Self-balancing pulse detonation engine

A pulse detonation, engine technology, applied in combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve problems such as inability to practical applications, and achieve reasonable design results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

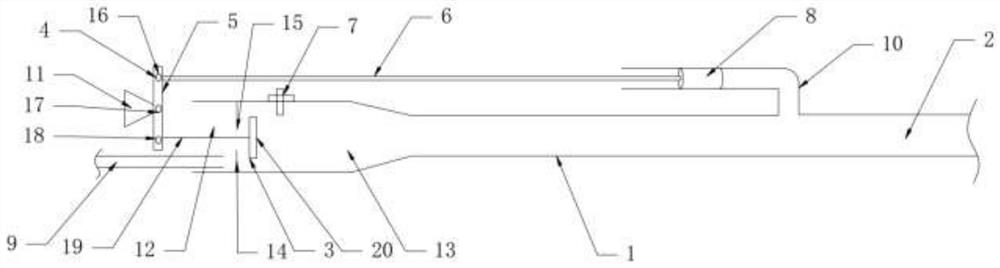

[0016] A self-balancing pulse detonation engine of the present invention will be further described in detail below with reference to the accompanying drawings.

[0017] combined with figure 1 , the present invention is introduced in detail.

[0018] A self-balancing pulse detonation engine includes an engine body 1, the engine body 1 includes a body 2, a valve 3, a hinge 4, a connecting rod 5, a top rod 6, a spark plug 7, a piston 8, an intake pipe 9, a self-balancing compensation Trachea 10, fulcrum 11;

[0019] The body 2 includes a chamber 12 and a combustion chamber 13, the chamber 12 is arranged on the left side of the body 2, and the combustion chamber 13 is arranged on the right side of the body 2; baffle plate 14, the baffle plate 14 is provided with an intake hole 15, one end of the valve 3 is arranged in the combustion chamber 13, and the other end is connected to the hinge 4 through the intake hole 15;

[0020] The hinge 4 includes a first hinge 16, a second hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com