Pressure-stabilizing switchable multi-section fuel injection system and method

A fuel injection and switching technology, applied in the direction of fuel injection device, fuel injection control, charging system, etc., can solve the problems of inability to control combustion well, lack of coherence and continuity, and increase the injection time, etc. The effect of improving fuel combustion efficiency, improving combustion efficiency, and expanding the volume of high-pressure oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

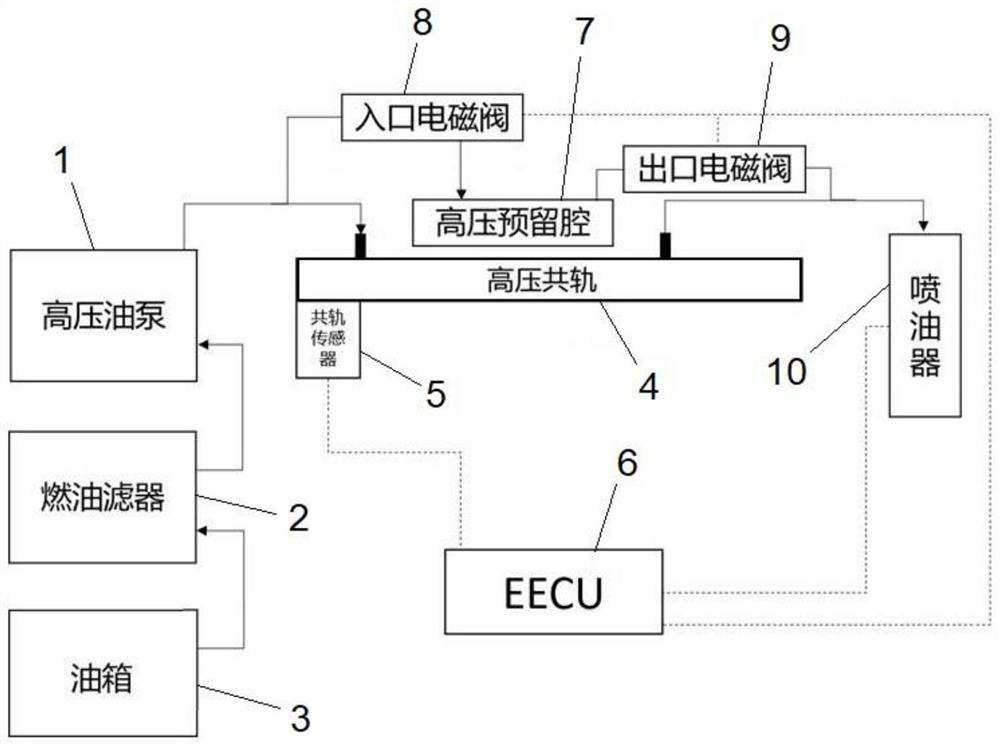

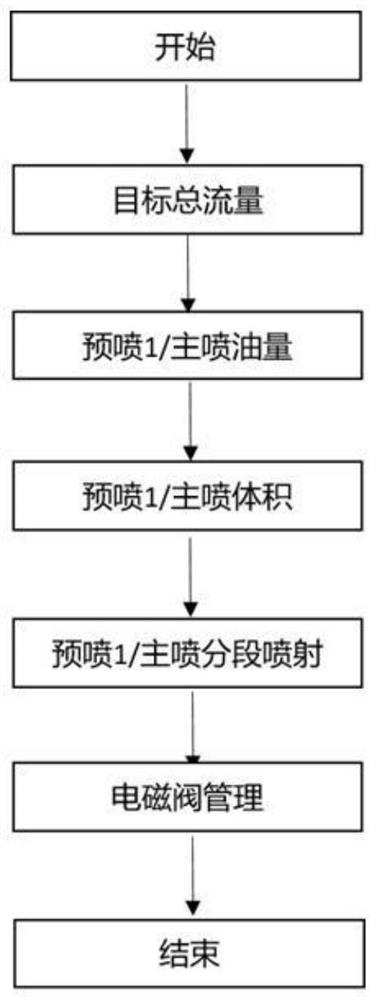

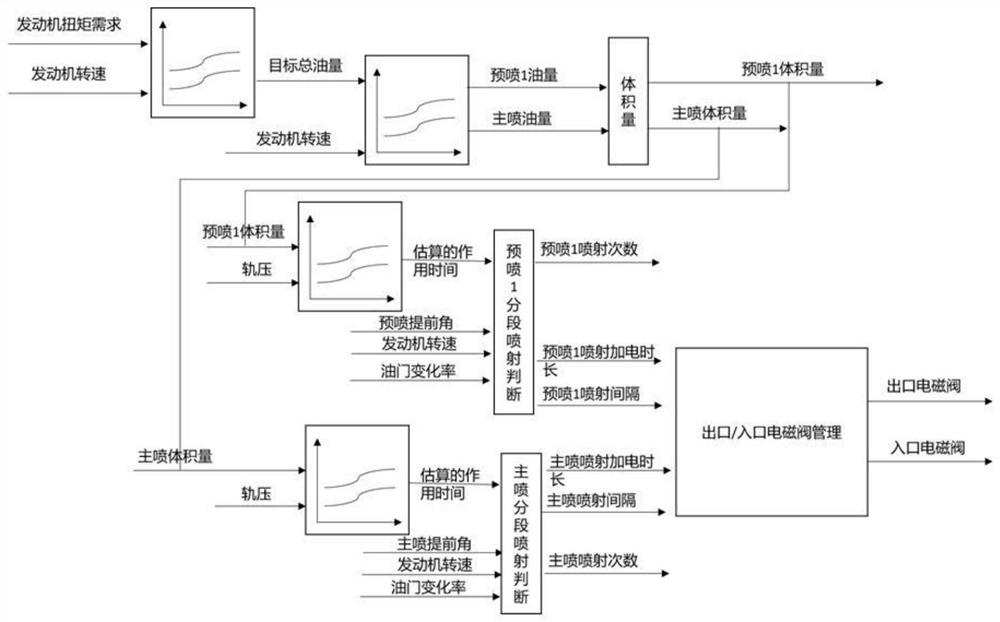

[0042] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help the understanding of the present invention, but do not constitute a limitation of the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as there is no conflict with each other.

[0043] Where "including", "having" and "comprising" are used as described in this specification, unless otherwise used, there may be another part or other parts, and the terms used may generally be singular but may also refer to the plural.

[0044] The features of the various embodiments of the present invention may be combined or spliced with each other, in part or in whole, and may be implemented in various configurations as will be well understood by those skill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com