Special construction auxiliary device for tunnel double-side-wall pilot tunnel method

A technology of double side wall guide pit and auxiliary device, applied in tunnels, mining devices, tunnel lining and other directions, can solve problems such as threatening the life safety of workers, collapse of tunnel side walls, poor support effect, etc., to improve the support effect, avoid The effect of stress concentration and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

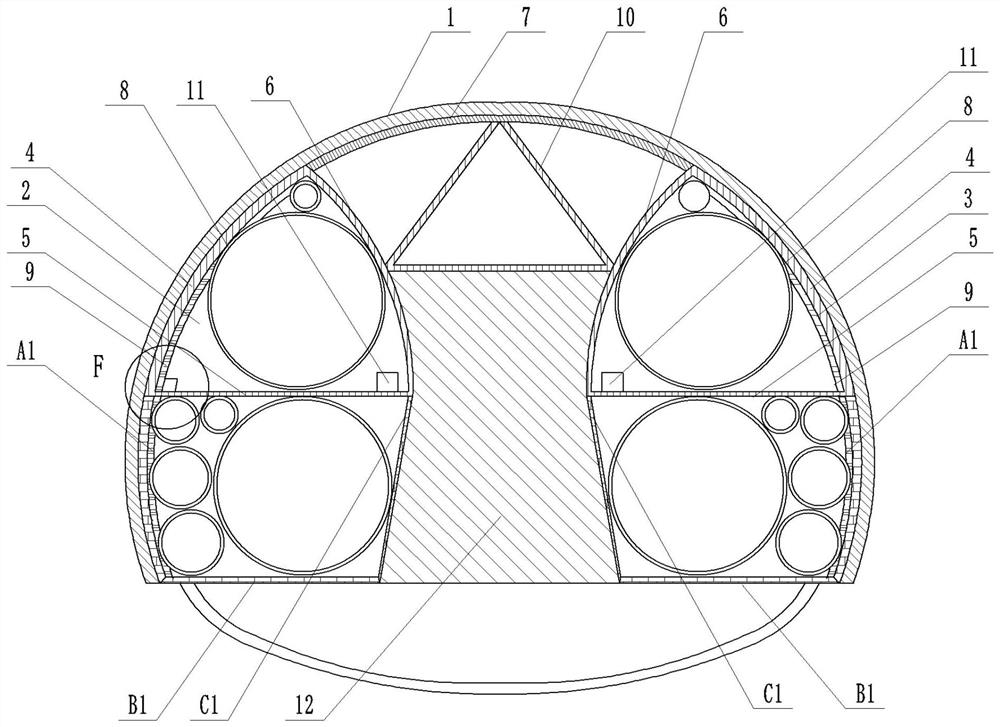

[0028] Example 1 is basically as attached figure 1 shown:

[0029] A special construction auxiliary device for tunnel 1 double side wall guide pit method, including upper support and lower support, and the upper support includes left side wall guide pit support 2, middle partition wall support 7 and right side wall guide pit support 3, the lower support includes the left lower step support and the right lower step support: the upper support and the lower support both include steel arches, the steel arches are provided with advanced conduits and steel mesh, and between the steel arches are provided with steel arches. Radial grouting pipe;

[0030] The shape of the left side wall guide pit support 2 and the right side wall guide pit support 3 is a triangle with an arc, and the left side wall guide pit support 2 and the right side wall guide pit support 3 include the first side 4 , the second side 5 and the third side 6; the first side 4 is in contact with the side wall of the ...

Embodiment 2

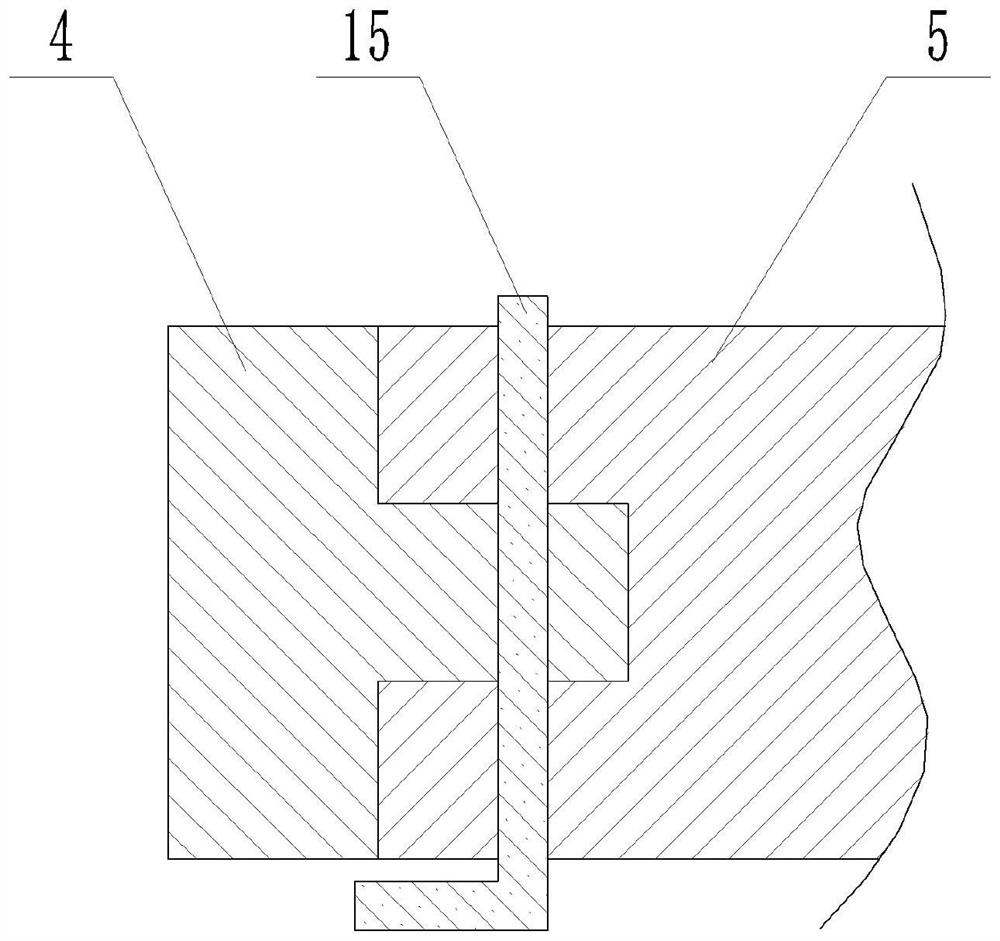

[0041] The difference between this embodiment 2 and the embodiment 1 is that, as shown in the appendix Figure 2-4 Shown: also includes a plug 15 and a heating device; the first side 4 and the second side 5 are connected in a detachable manner, the first side 4 is in a convex shape, and the second side 5 is provided with a The convex part of the strip edge 4 is matched with the groove. The first side 4 and the second side 5 are provided with through holes into which the plug 15 can be inserted. The plug 15 is L-shaped. The plug 15 includes a vertical side and a horizontal side connected by end faces. The horizontal side is located in the through hole. One side 4 and the second side 5 are fixed together, the vertical side is in contact with the heating device, the other end of the heating device is in contact with the wall of the tunnel 1, the heating device includes the first layer and the second layer, the first layer and the second layer Through the film connection, the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com