Split-level discontinuous ribbed hollow interlayer concrete filled steel tubular column-steel beam joint

A technology for concrete-filled steel tubular columns and concrete, which is used in construction, building construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

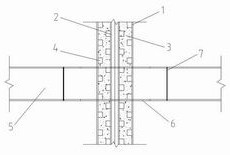

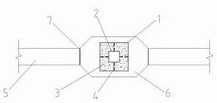

[0020] like figure 1 and figure 2 As shown, a split-level discontinuous ribbed hollow sandwich CFST column-steel beam joint component is processed according to the required design size: outer steel pipe, square inner steel pipe, split-level intermittent solid rib, outer reinforcement ring and steel beam; according to the design Positioned on the square outer steel pipe 1 and the inner square steel pipe 2, the staggered intermittent solid rib 4 is welded, and the staggered intermittent solid rib 4 is symmetrically distributed in the node area up and down, and the square sleeve square hollow sandwich reinforcement ring 6 is vertically welded to the outer steel pipe 1. Design location. The square outer steel pipe 1 and the square inner steel pipe 2 are arranged concentrically to form a cavity, and then the dense concrete 3 is poured into the cavity. When the concrete c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com