Square sleeve circular hollow interlayer steel pipe concrete column and steel beam joint internally provided with PBL ribs

A technology of steel pipe concrete columns and round steel pipes, which is applied in the direction of construction and building construction, can solve the problems of strength reduction, joint shear damage, etc., and achieve high bearing capacity, increased stiffness and deformation resistance, and clear force transmission paths Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

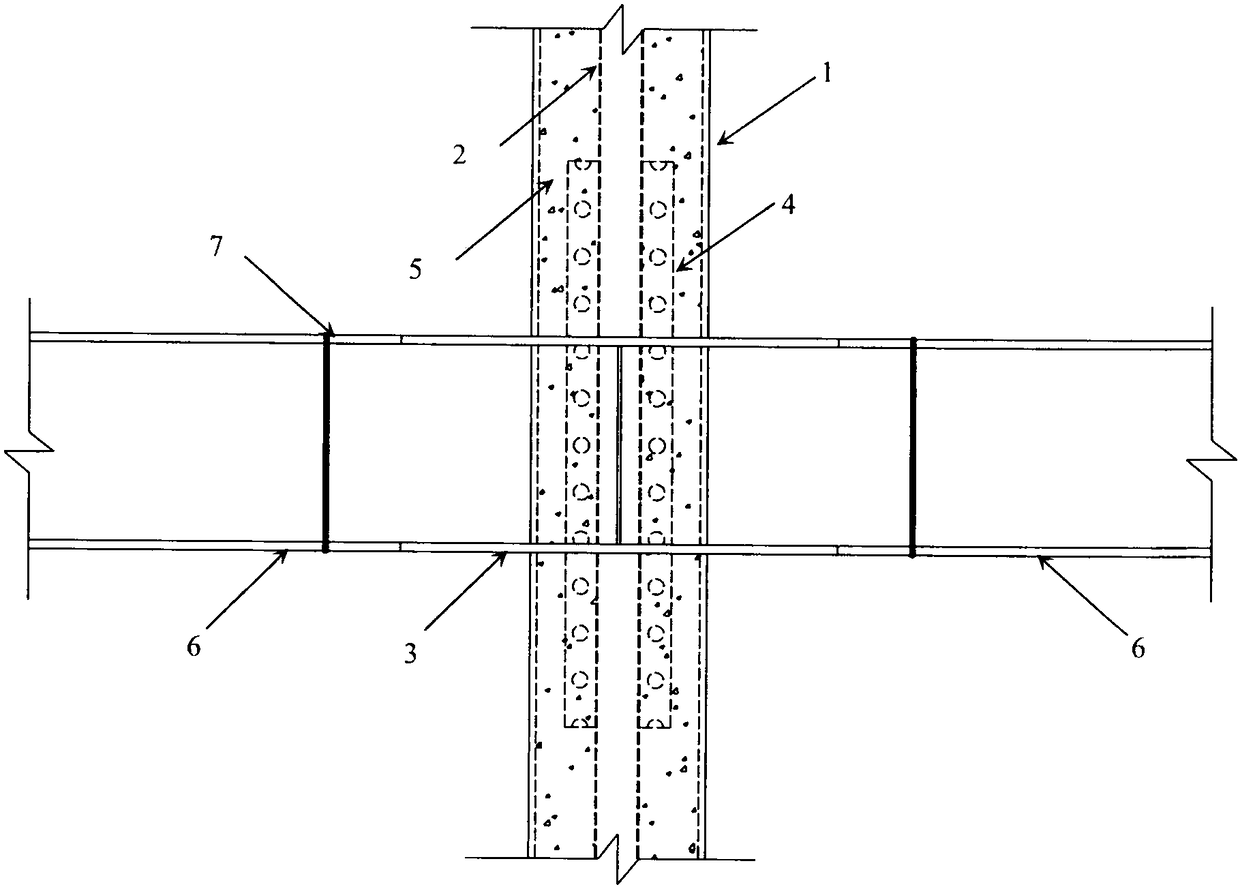

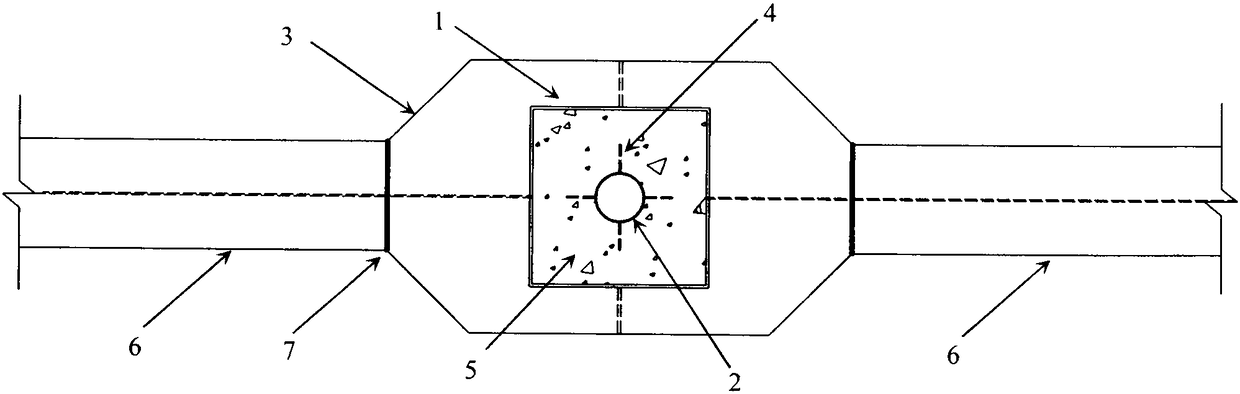

[0015] Such as figure 1 with figure 2 As shown, process the outer square steel pipe, the inner steel pipe, the PBL rib, the outer reinforcing ring and the steel beam according to the design size; weld the PBL rib 4 on the inner steel pipe 2 according to the design position, and the stiffener 4 is distributed symmetrically up and down In the node domain, the square sleeve circle hollow interlayer reinforcement ring 3 is vertically welded to the design position of the outer square steel pipe 1, the circle inner steel pipe 2 and the circle sleeve circle hollow interlayer outer steel pipe 1 are concentrically arranged to form a cavity, and then poured into the cavity For dense concrete, when the concrete curing reaches the design strength value, the steel beam 6 and the reinforcing ring 3 are connected by welding to form a joint with a PBL rib square sleeve and a hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com