An "l" type partially prefabricated composite beam and its construction method and application

A technology of composite beams and prefabricated slabs, which is applied to long-strip structural components used for load-bearing, buildings, building components, etc., can solve the problems of not paying enough attention to the connection between beams and floors, only paying attention to the main performance of beam structures, and personal safety threats , to achieve the effect of ensuring normal use and carrying capacity, improving the restraint effect, and enhancing the restraint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

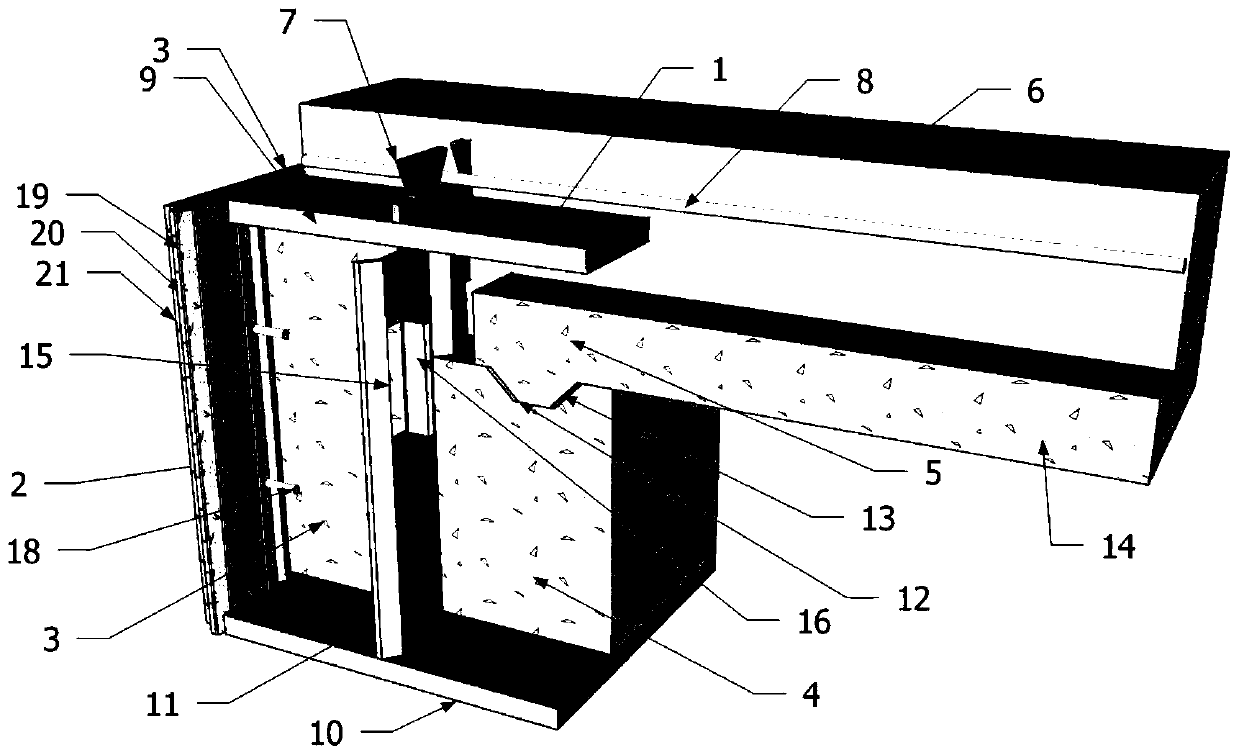

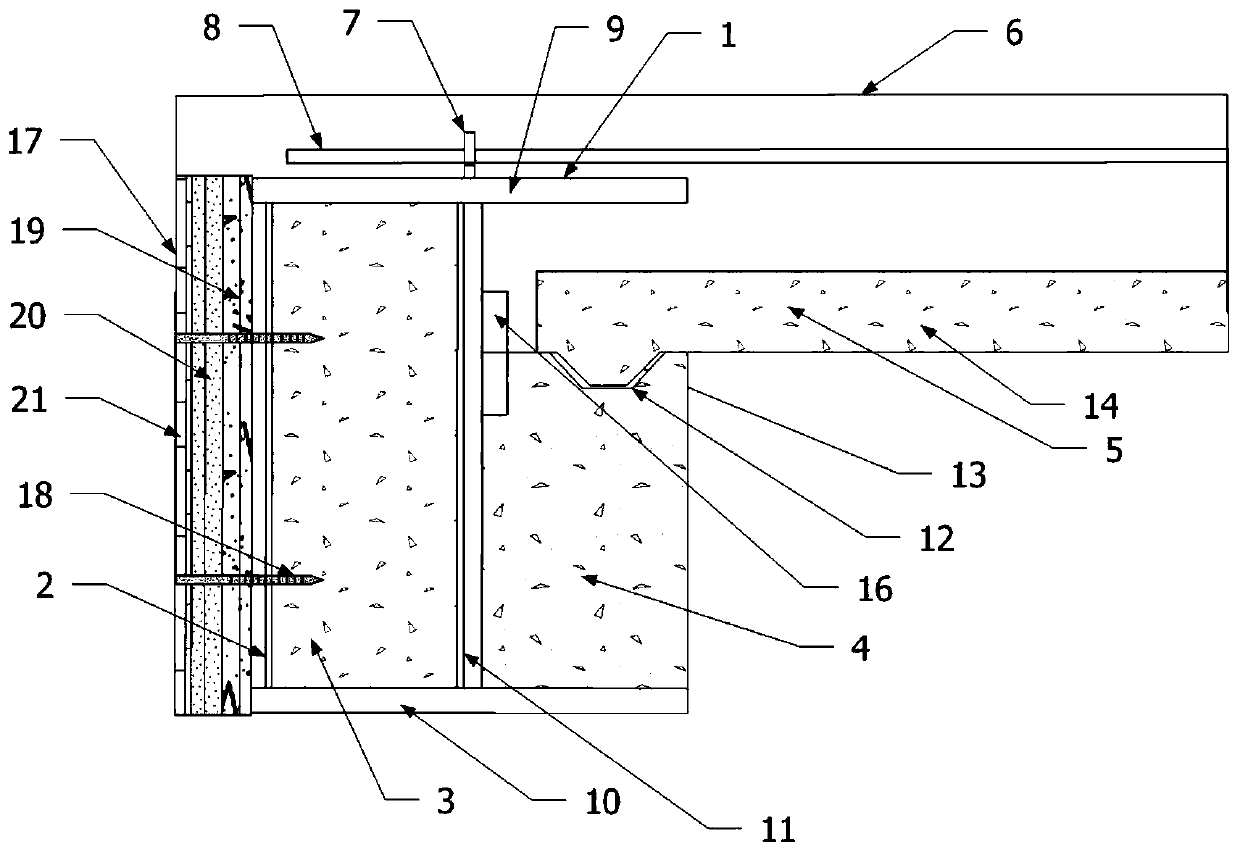

[0065] Example 1: An "L"-shaped partially prefabricated composite beam

[0066] Such as Figure 1-2 , an "L"-shaped partially prefabricated composite beam includes H-shaped steel 1, panel 2, first precast concrete 3, second precast concrete 4, precast concrete floor slab 5, cast-in-place concrete 6, connector 7 and longitudinal reinforcement 8;

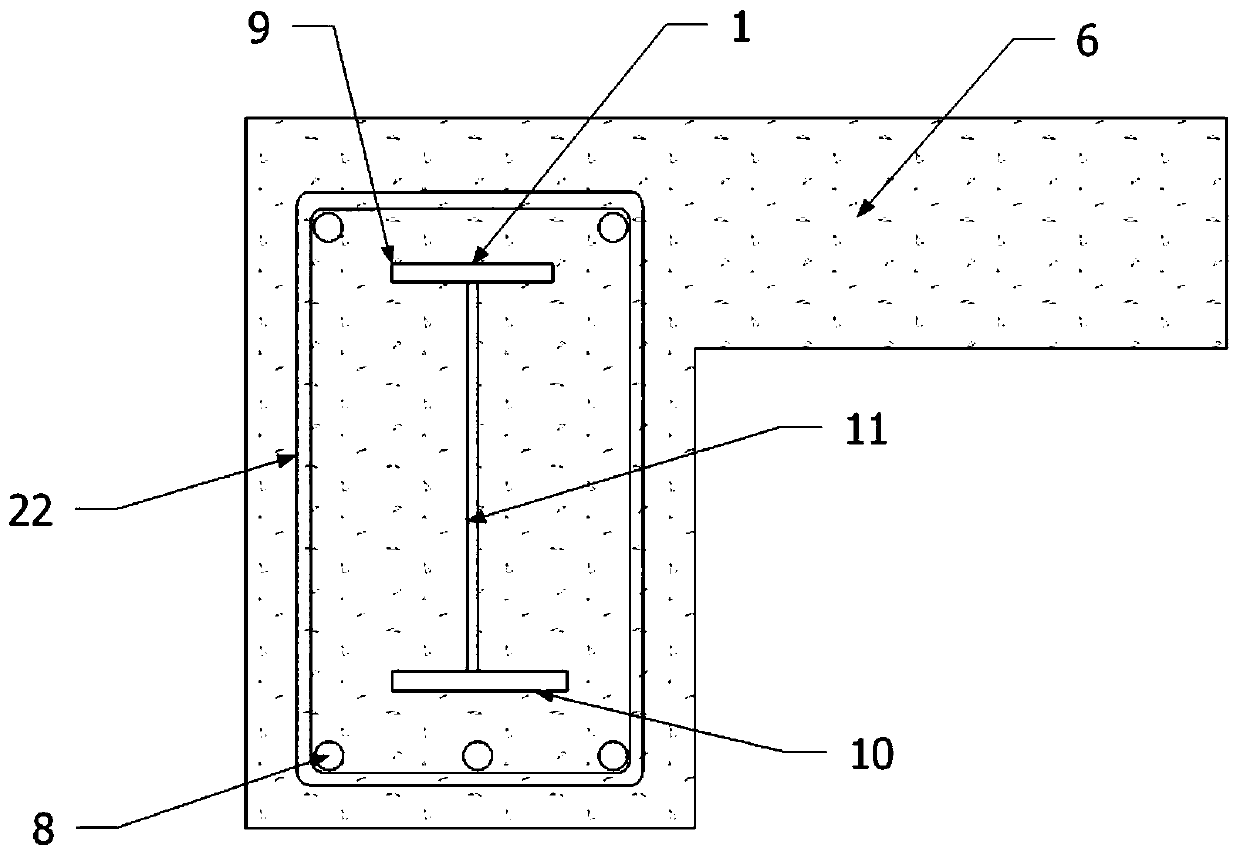

[0067] The H-shaped steel 1 includes an upper flange plate 9, a lower flange plate 10 and a web 11;

[0068] The trim plate 2 is located on one side of the H-shaped steel 1 and the two ends of the trim plate 2 are respectively connected to the upper flange plate 9 and the lower flange plate 10 of the H-shaped steel 1;

[0069] The first precast concrete 3 is filled in the cavity formed by the upper flange plate 9, the lower flange plate 10, the web plate 11 and the trim plate 2 of the H-shaped steel 1;

[0070] The second prefabricated concrete 4 is located on the other side of the H-shaped steel 1 that is not connected to the panel...

Embodiment 2

[0094] Example 2: A construction method for "L"-shaped partially prefabricated composite beams

[0095] Specific steps are as follows:

[0096] (1) According to the design, three-sided punching is carried out on the web 11 of the H-shaped steel 1, and the punched part is bent to obtain the H-shaped steel 1 provided with the opening 15 and the shear key 16; It is welded between the upper flange plate 9 and the lower flange plate 10 of the H-shaped steel 1, and the connecting piece 7 is welded above the upper flange plate 9 to obtain the steel frame; the prefabricated plate 17 is fixed to the trim plate by bolts 18 2, the first precast concrete 3 is poured in the cavity formed by the upper flange plate 9, the lower flange plate 10, the web 11 and the trim plate 2 of the H-shaped steel 1, and the second precast concrete 4 is poured in the H-shaped steel Between the upper flange plate 9 and the lower flange plate 10 of 1, a prefabricated part A is obtained;

[0097] (2) Accordin...

Embodiment 3

[0099] Example 3: Detection of an "L"-shaped partially prefabricated composite beam

[0100] Specific steps are as follows:

[0101] A "L" type partial prefabricated composite beam:

[0102] The size of the upper flange plate is 200mm×6mm; the size of the lower flange plate is 200mm×8mm; the height of the web plate is 416mm and the thickness is 4mm; the size of the side plate is 416mm×3mm and the specification is W94×20×2; the opening The size of the shear key is 200mm×20mm, the distance between the symmetry axis parallel to the longitudinal direction of the beam and the lower flange plate is 292mm; the size of the single-row hole steel plate shear connector is 25mm×4mm, and the hole is trapezoidal , the side lengths of the upper bottom and the lower bottom are 15mm and 30mm respectively; the steel plates are all made of Q235; the diameter of the longitudinal reinforcement is 8mm, and the steel bar of HRB335 grade is used; the diameter of the self-tapping bolt is 10mm, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com