Method for extracting castor silk fibroin by using modified block copolymer and calcium chloride

A technology of block copolymer and silk fibroin, which is applied in the field of protein extraction, can solve the problems of high toxicity, great harm to human body, and does not conform to green health, etc., and achieves the effects of mild working conditions, resource saving and easy recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

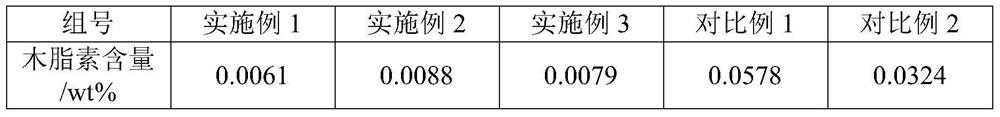

Examples

Embodiment 1

[0026] 1) Weigh 4.0g of castor cocoons and cut them open, place them in a clean beaker, wash away surface contaminants with ultrapure water, and dry.

[0027] 2) Weigh 0.14g of modified block copolymer, Na 2 CO 3 0.14g, Na 2 HPO 4 0.14 g, dissolved in 9 mL of ultrapure water, and sonicated at 30°C for 15 min to obtain a mixed solution. The castor silk was boiled for 35 min in the mixed solution at a liquor ratio of 1:100, and degummed for three times in total. The modified block copolymer is a block copolymer formed by the copolymerization of methyl propylene oxide and propylene oxide, followed by adding fatty alcohol polyoxyethylene ether; methyl propylene oxide, propylene oxide and fatty alcohol polyoxyethylene The molar ratio of vinyl ether was 3.2:1.1:0.6.

[0028] 3) After degumming, the castor silk was washed with ultrapure water, then rinsed with absolute ethanol, washed three times, and placed in a 60° C. oven to obtain dry silk fibroin fibers.

[0029] 4) Degu...

Embodiment 2

[0032] 1) Weigh 5.0g of castor cocoons and cut them open, place them in a clean beaker, wash off surface contaminants with ultrapure water, and dry.

[0033] 2) Weigh 0.15g of modified block copolymer, Na 2 CO 3 0.15g, Na 2 HPO 4 0.15 g, dissolved in 10 mL of ultrapure water, and sonicated at 30 °C for 15 min to obtain a mixed solution. The castor silk was boiled in the mixed solution at a liquor ratio of 1:98 for 38 min, and degummed for three times in total. The modified block copolymer is a block copolymer formed by the copolymerization of methyl propylene oxide and propylene oxide, followed by adding fatty alcohol polyoxyethylene ether; methyl propylene oxide, propylene oxide and fatty alcohol polyoxyethylene The molar ratio of vinyl ether was 3.6:1.3:0.7.

[0034] 3) After degumming, the castor silk was washed with ultrapure water, then rinsed with absolute ethanol, washed three times, and placed in a 62° C. oven to obtain dry silk fibroin fibers.

[0035] 4) Degu...

Embodiment 3

[0038] 1) Weigh 4.5g of castor cocoons and cut them open, place them in a clean beaker, wash off surface contaminants with ultrapure water, and dry.

[0039] 2) Weigh 0.16g of modified block copolymer, Na 2 CO 3 0.16g, Na 2 HPO 4 0.16 g, dissolved in 11 mL of ultrapure water, and sonicated at 30°C for 15 min to obtain a mixed solution. The castor silk was boiled in the mixed solution for 40 min at a liquor ratio of 1:95, and degummed for three times in total. The modified block copolymer is a block copolymer formed by the copolymerization of methyl propylene oxide and propylene oxide, followed by adding fatty alcohol polyoxyethylene ether; methyl propylene oxide, propylene oxide and fatty alcohol polyoxyethylene The molar ratio of vinyl ether was 3.6:1.7:0.8.

[0040] 3) After degumming, the castor silk was washed with ultrapure water, then rinsed with absolute ethanol, washed three times, and placed in a 65° C. oven to obtain dry silk fibroin fibers.

[0041] 4) Degum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com