Efficient production system for glass containers

A production system and glass container technology, applied in glass production, glass molding, glass manufacturing equipment, etc., can solve problems such as handle seam defects and low efficiency of wine dispensers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is further described in detail by specific embodiments:

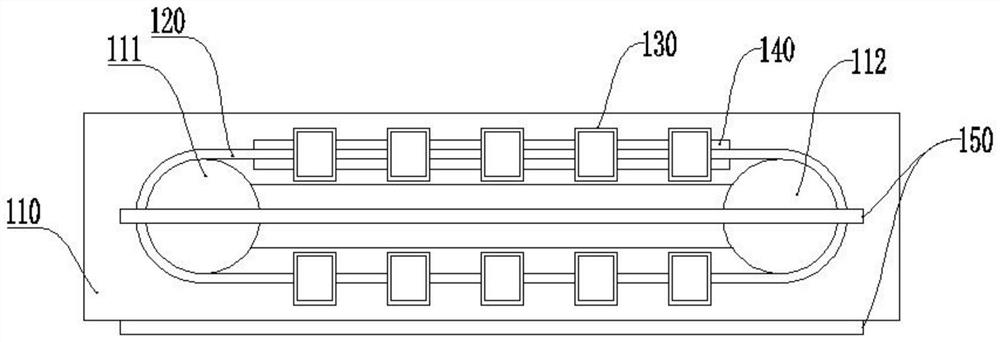

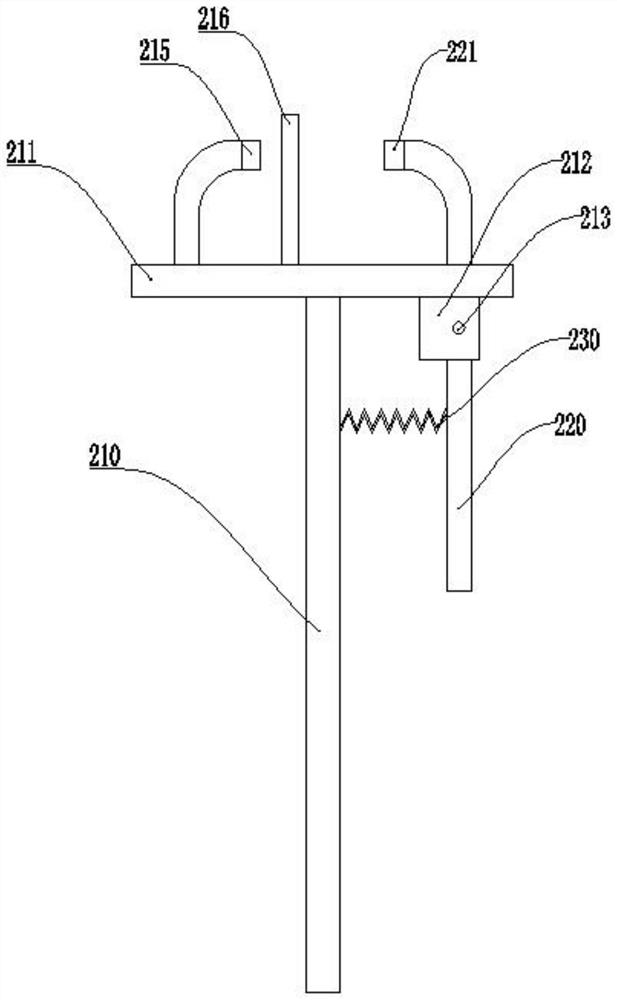

[0035] Reference numerals in the accompanying drawings include: intermediate material conveyor 1, machine base 110, driving sprocket 111, driven sprocket 112, chain 120, placing table 130, limit block 140, support rod 150, transfer fixture 2 , handle 210, support plate 211, bottom block 212, pin 213, fixed clamp arm 215, stopper 216, movable block 220, movable clamp arm 221, spring 230, handle bonding table 3, base 310, bracket 320, Support plate 321, support rod 322, reinforcement block 323, material receiving chute 330, water tank 340, torch 350, forming tool 4, base 41, support column 42, loading seat 43, blocking rod 44, baffle 45, gas pipe 46 , Support rod 47 , exhaust hole 48 , forming die 5 , pallet 51 , die base 52 , forming base 53 , positioning rod 54 , positioning groove 55 , forming groove 56 .

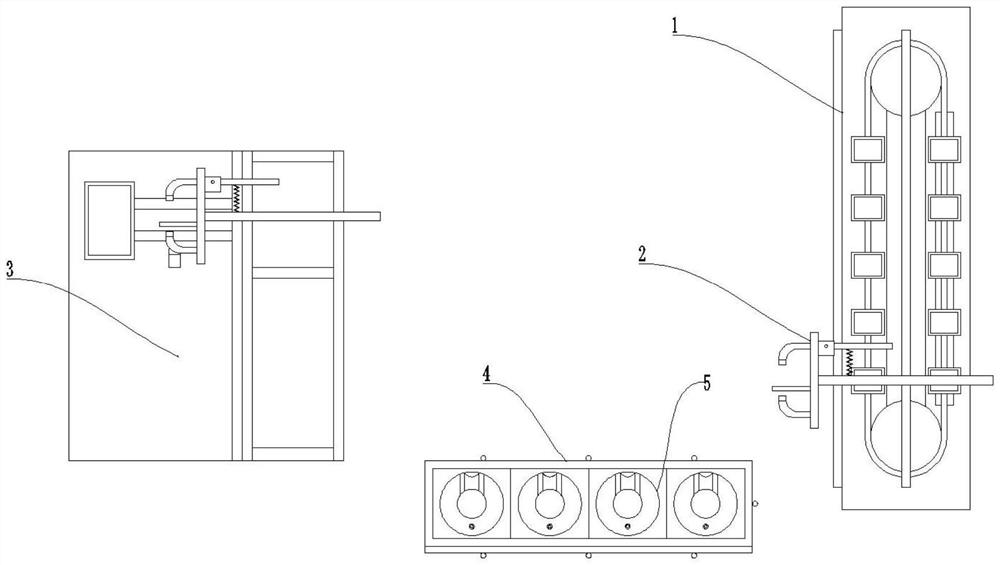

[0036] The example is basically as attached figure 1 Shown: An efficient production system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com