Application of solid acid as carbon nanotube dopant and doping method

A carbon nanotube thin film and dopant technology, applied in chemical instruments and methods, conductive layers on insulating carriers, carbon compounds, etc. Optical performance and other issues, to achieve the effect of low preparation cost, good transparent conductivity, and reduce square resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] According to a preferred embodiment of the present invention, the polyacid clusters and heteropolyacid clusters are selected from phosphomolybdic acid H 3 PMo 12 O 40 , Silicomolybdic acid H 4 SiMo 12 O 40 , phosphotungstic acid H 3 PW 12 O 40 , phosphotungstic acid H 6 P 2 W 18 O 62 , arsenic acid H 3 AsW 12 O 40 , arsenic acid H 6 As 2 W 18 O 62 , silicotungstic acid H 4 SiW 12 O 40 and borotungstic acid H 3 BW 12 O 40 one or more of them.

[0032] According to a further preferred embodiment of the present invention, the polyacid clusters and heteropolyacid clusters are selected from phosphotungstic acid H 3 PW 12 O 40 , silicotungstic acid H 4 SiW 12 O 40 and phosphomolybdic acid H 3 PMo 12 O 40 one or more of them. The inventors found that the above-mentioned polyacid clusters and heteropolyacid clusters are selected as dopants for carbon nanotube films, which have the best effect on improving the conductivity of carbon nanotube film...

Embodiment 11

[0099] Example 1 1.0g / mL phosphotungstic acid aqueous solution doped carbon nanotube film

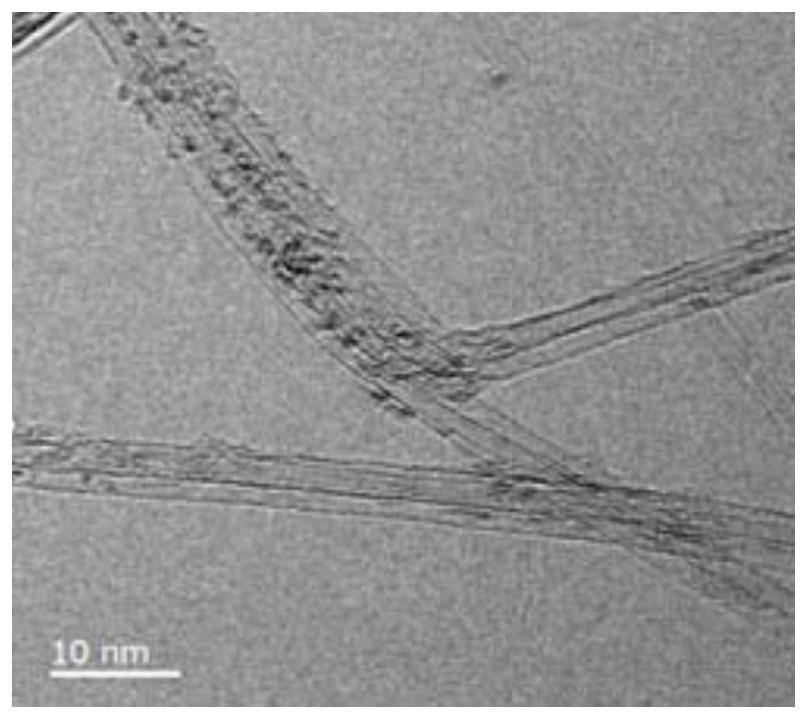

[0100] Weigh 7.0gH 3 PW 12 O 40 Dissolve in 7mL of ultrapure water, soak the carbon nanotube film supported on the glass substrate in the aqueous solution of phosphotungstic acid, the carbon nanotube film will fall off the glass substrate and float on the liquid surface. After soaking for 12 hours, carefully remove the carbon nanotube film on the liquid surface with a glass slide, gently rinse off the excess phosphotungstic acid remaining on the glass slide with ultrapure water, and gently dry it with argon. During the whole process, care should be taken not to damage the integrity of the carbon nanotube film.

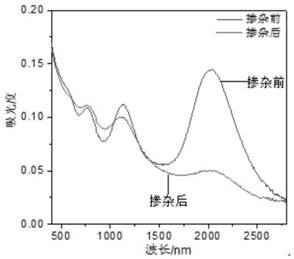

[0101]The square resistance of carbon nanotube films and its transmittance at 550nm wavelength were tested by four-probe square resistance meter and UV-visible-near-infrared absorption spectrometer. The square resistance of the carbon nanotube film before doping is 227Ω / sq.,...

Embodiment 2

[0102] Example 2 0.5g / mL phosphotungstic acid aqueous solution doped carbon nanotube film

[0103] The preparation process of Example 1 was repeated, except that the concentration of the aqueous phosphotungstic acid solution was 0.5 g / mL.

[0104] After testing, the square resistance of the carbon nanotube film before doping is 306Ω / sq., and the light transmittance is 91.76%; after doping, the square resistance of the carbon nanotube film is 198Ω / sq. The rate is 90.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com