Manipulator for grabbing and placing oral instrument

A technology of manipulators and instruments, applied in the field of manipulators, can solve the problems of difficult sorting, small space between instruments, and low work efficiency, and achieve the effects of saving storage space costs, improving packaging efficiency, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

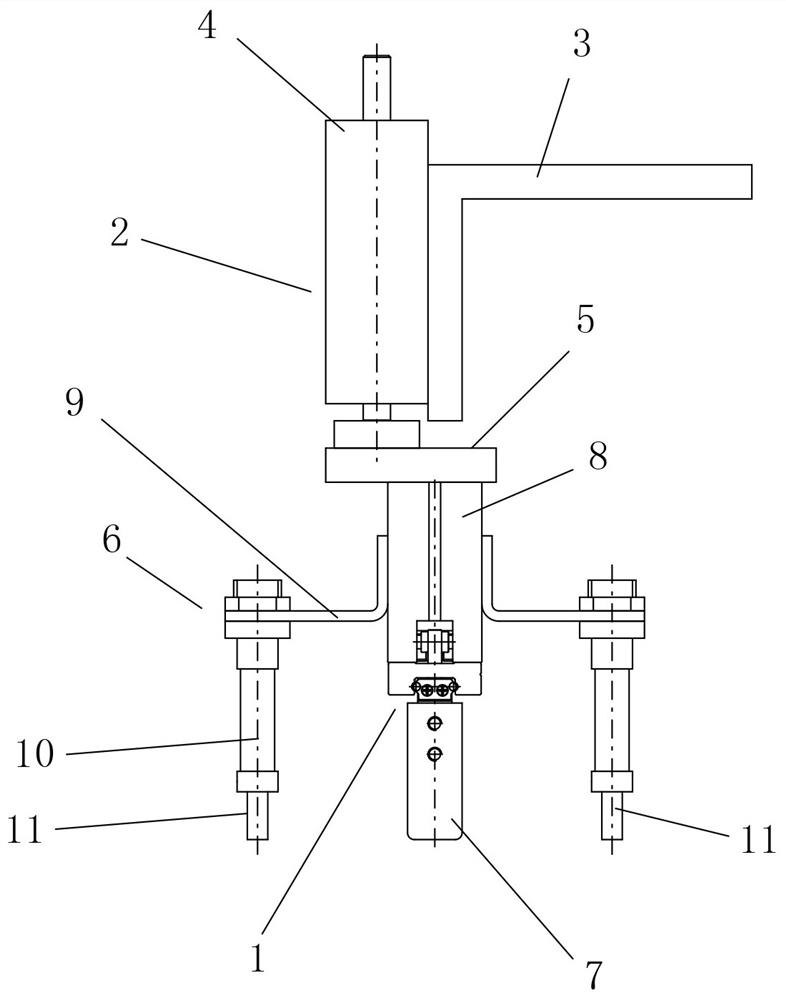

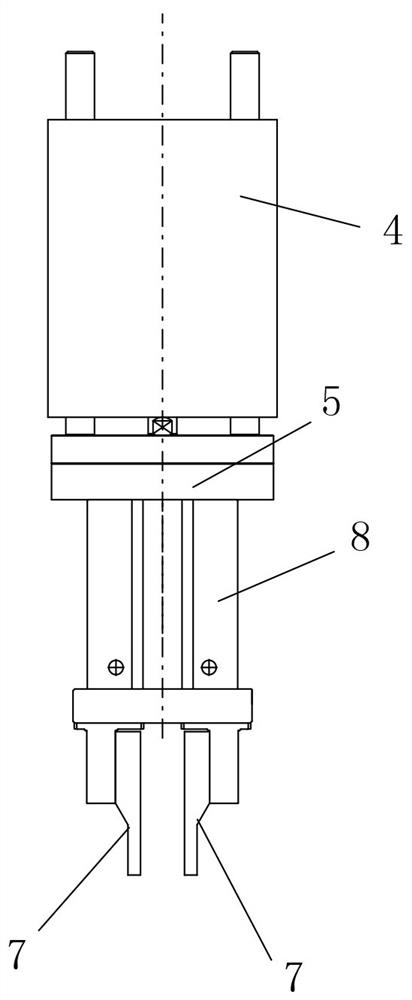

[0023] according to figure 1 , figure 2 In this embodiment, a manipulator for grasping and placing oral instruments includes a clamping assembly 1 for clamping a single oral instrument. Above the clamping assembly 1 is a device that can drive the clamping assembly 1 to move up and down. The lifting assembly 2 is provided with a mounting and fixing plate 3 on one side of the lifting assembly 3 .

[0024] The clamping assembly 1 includes a pair of clamping blocks 7 and a clamping cylinder 8 that drives the clamping blocks 7 to clamp or loosen. The clamping blocks 7 are fixed on the output end below the clamping cylinder 8 . , the upper end of the clamping cylinder 8 is connected with the lifting assembly 2 .

[0025] Specifically, the lifting assembly 2 includes a lifting cylinder 4, the output end of the lifting cylinder 4 is connected to the upper end of the clamping cylinder 8 through the first connecting plate 5, and the lifting cylinder 4 is fixed on the installation fix...

Embodiment 2

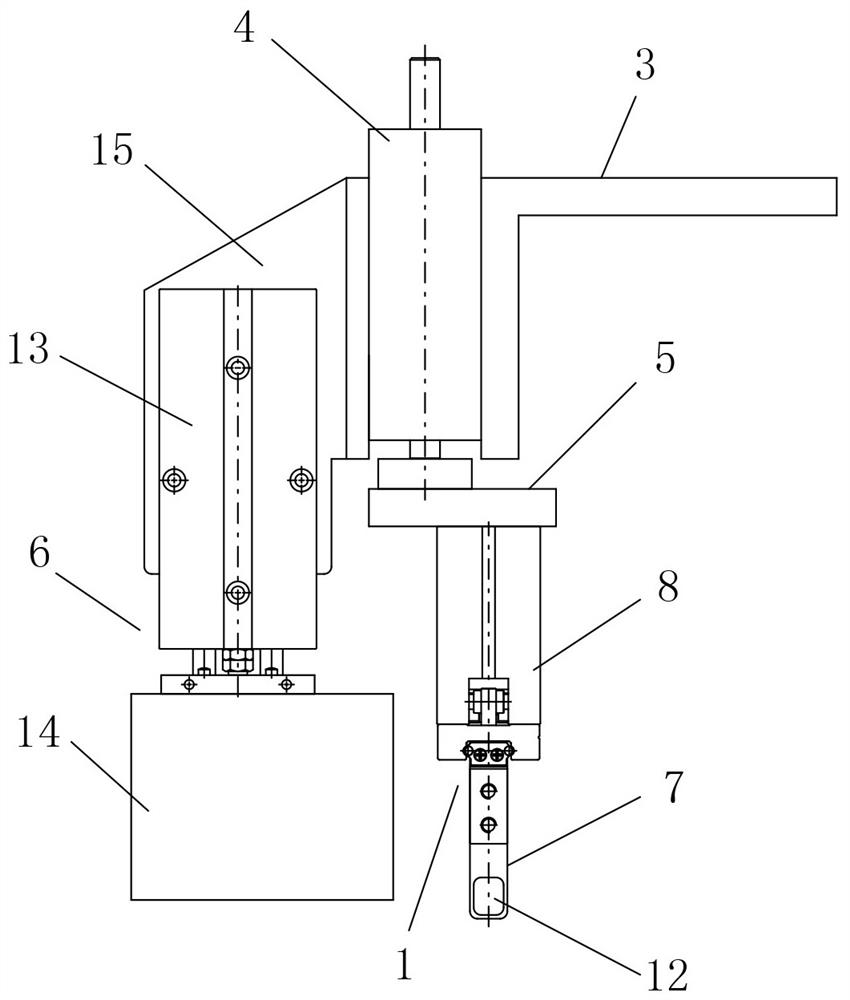

[0030] according to image 3 , Figure 4 , Different from the first embodiment, the inner side of the lower end of the clamping block 7 in this embodiment is provided with a rubber block 12, the rubber block 12 is used to increase the frictional force of the clamping surface and prevent the equipment from grasping and moving fall off. The pressing member 6 is a lifting and pressing block assembly. The lifting and pressing block assembly includes a pressing cylinder 13 , a pressing block 14 and a second connecting plate 15 . The pressing block 14 is fixed on the bottom of the pressing cylinder 13 . At the output end of the lower end, the bottom surface of the pressing block 14 is an isosceles triangle or an isosceles trapezoid, and the bottom surface of the pressing block 14 is used to press other oral instruments that do not need to be clamped to prevent the oral instruments from being clamped. stick to each other. The material pressing cylinder 13 is connected with the lif...

Embodiment 3

[0034] according to Figure 5 , Image 6 , and the difference from the first embodiment is that the inner side of the lower end of the clamping block 7 of the clamping assembly 1 is provided with a triangular protrusion 16; the rest of the structure is the same as that of the first embodiment. When the triangular protrusion 16 is used for clamping a polygonal probe or mouth mirror, the wrapping surface is increased to prevent it from falling off during grasping and movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com