Hierarchical pore metal organic framework material as well as preparation method and application thereof

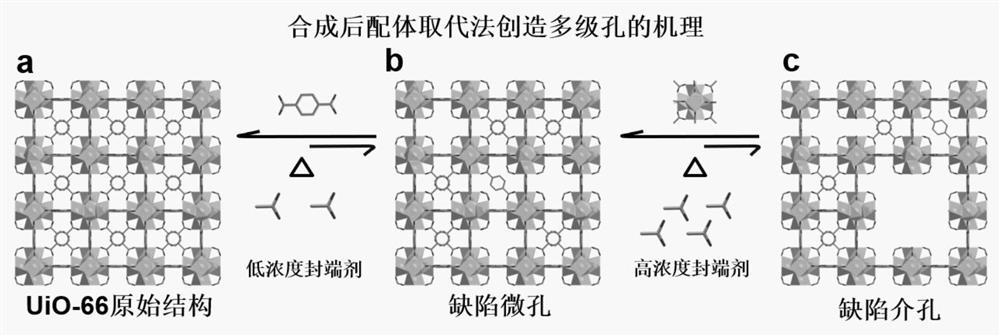

A metal-organic framework and hierarchical pore technology, which is applied in the fields of organic chemistry, chemical instruments and methods, and reductive alkylation preparation, etc., can solve the problems of difficult to control the etching/destruction of the parent MOF structure, and achieve the effect of a simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

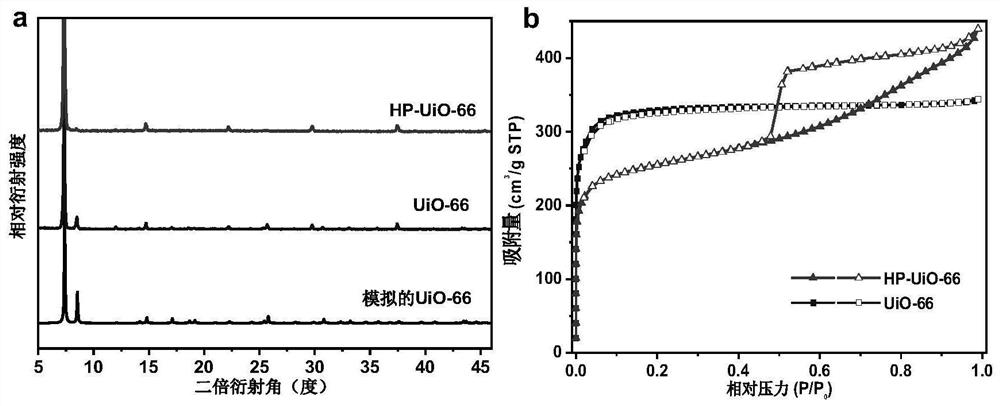

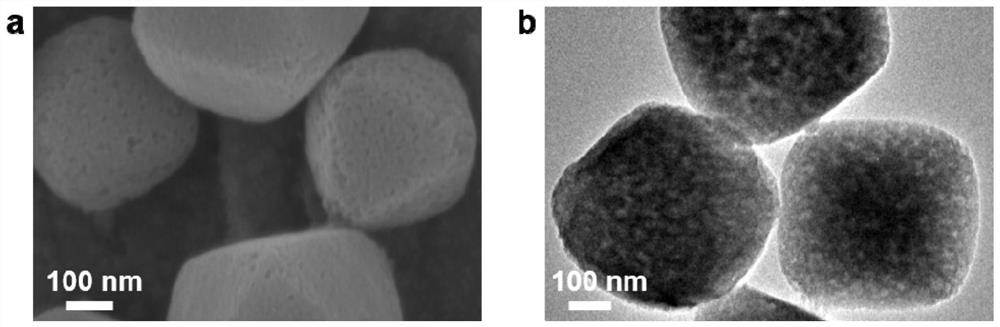

[0088] The preparation of HP-UiO-66 by a reflux-assisted post-synthesis ligand replacement method is carried out as follows:

[0089] 1.1 Put 35 mg of ZrCl 4 Dissolved by sonication into 10 mL of DMF, followed by the addition of 25 mg of H 2 BDC. After the reaction solution was sonicated for 20 minutes, 0.7 mL of acetic acid was added, and then packaged into a 20 mL glass reaction vial, and reacted at 120° C. for 24 hours. After cooling to room temperature, the product was collected by centrifugation, washed with DMF and MeOH to remove unreacted raw materials, and then dried at 85°C for 12 hours for use.

[0090] 1.2 Add 656 mg of sodium acetate, 100 mg of PVP K30 and 20 mL of deionized water into a 100 mL round-bottomed flask, and ultrasonically dissolve it fully. Immediately, 100 mg of UiO-66 was dispersed therein, and the reactant was heated to 100° C. and refluxed with stirring for 12 hours. After cooling to room temperature, the product was collected by centrifugation...

Embodiment 2

[0095] The large-scale synthesis of HP-UiO-66 by a reflux-assisted post-synthesis ligand replacement method was carried out as follows (see appendix). Figure 4 ):

[0096] 2.1 Add 1 mL of concentrated hydrochloric acid and 150 mL of DMF to a 250 mL round-bottomed flask, and then add 2.33 g of ZrCl 4, 1.82g of H 2 BDC, 24.4 g of benzoic acid. The reaction solution was sonicated for 20 minutes to be fully dissolved, and then the reaction solution was heated and stirred at 120° C. for 2 to 3 days. After cooling to room temperature, the product was collected by centrifugation, washed with DMF and MeOH to remove unreacted raw materials, and then dried at 85°C for 12 hours for use. Synthesize in five batches and collect 10 g of UiO-66.

[0097] 2.2 Add 32g of sodium acetate, 4g of PVP K30 and 800mL of deionized water to a 1L round-bottomed flask, and stir to dissolve it fully. Then 10 g of the above UiO-66 was dispersed into it, and the reactant was heated to 100° C., stirred ...

Embodiment 3

[0102] The preparation of Pt@HP-UiO-66 by a reflux-assisted post-synthesis ligand replacement method was carried out as follows:

[0103] 3.1 Put 0.5mL of H with a concentration of 100mg / mL 2 PtCl 6 The solution and 222 mg of PVP (MW: 55000) were added to a round bottom flask containing 20 mL of ethylene glycol. The reaction was carried out at 180°C for 10 minutes. After cooling to room temperature, the product was collected by centrifugation, washed with n-hexane and acetone, and the obtained Pt NPs were dispersed in 20 mL of DMF for use.

[0104] 3.2 51 mg of ZrCl 4 Dissolved by sonication into 5 mL of DMF, and another 66.5 mg of H 2 BDC was sonicated into 5 mL of DMF. The above solution, 1 mL of DMF solution containing Pt NPs (1.0 mg / mL) and 1.2 mL of acetic acid were added to a 20 mL glass reaction flask, and reacted at 120° C. for 24 hours. After cooling to room temperature, the product Pt@UiO-66 was collected by centrifugation, washed with DMF and MeOH to remove un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com