Vertical cavity surface emitting laser and preparation method thereof

A vertical cavity surface emission and laser technology, applied in the field of lasers, can solve the problems of free carrier absorption and self-heating, and achieve the effects of reducing absorption and self-heating, improving heat dissipation performance, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe in detail the technical content, structural features, and achieved effects of the present invention, detailed descriptions are given below with reference to the embodiments and the accompanying drawings.

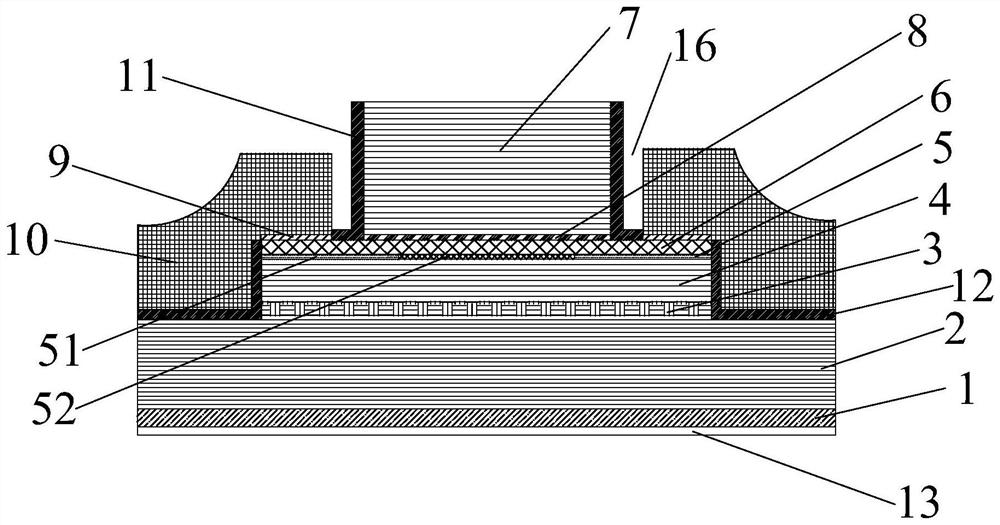

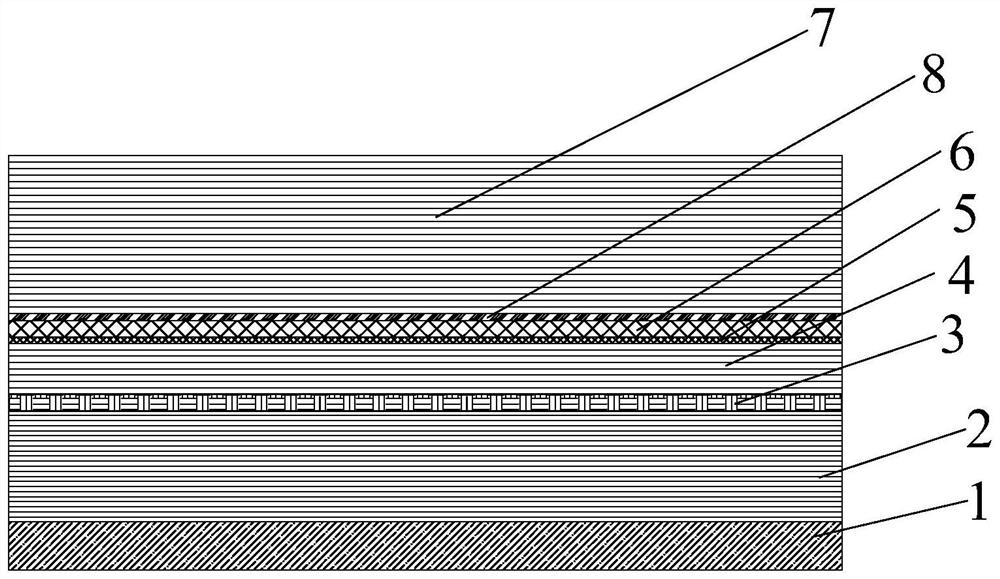

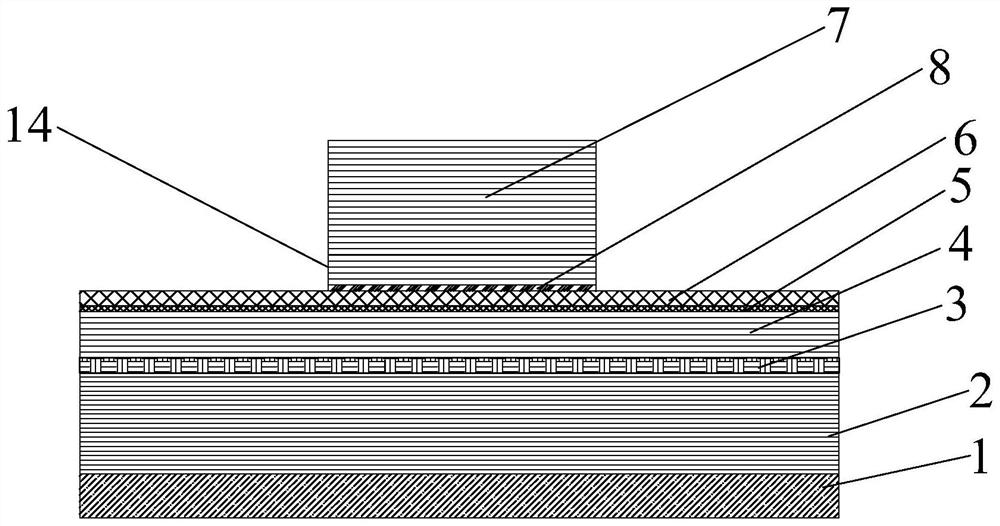

[0027] like figure 1 As shown in the figure, a vertical cavity surface emitting laser according to an embodiment of the present invention includes a substrate 1, a lower grating layer 2, an active layer 4, a contact layer 6 and an upper grating layer 7 which are sequentially arranged from bottom to top. 7 is protruded in the middle of the contact layer 6 and a first step portion 14 is formed between the outer peripheral wall of the upper grating layer 7 and the contact layer 6, and the contact layer 6 and the active layer 4 are protruded from the lower part. A second step portion 15 is formed in the middle of the grating layer 2 and between the contact layer 6 and the outer peripheral wall of the active layer 4 and the lower grating layer 2 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com