Method for coating positive electrode material precursor with tin base and positive electrode material precursor

A cathode material and precursor technology, applied in the field of lithium battery cathode materials, can solve problems such as hindering the migration rate of lithium ions, decreasing the electrochemical performance of cathode materials, and increasing the resistivity of cathode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

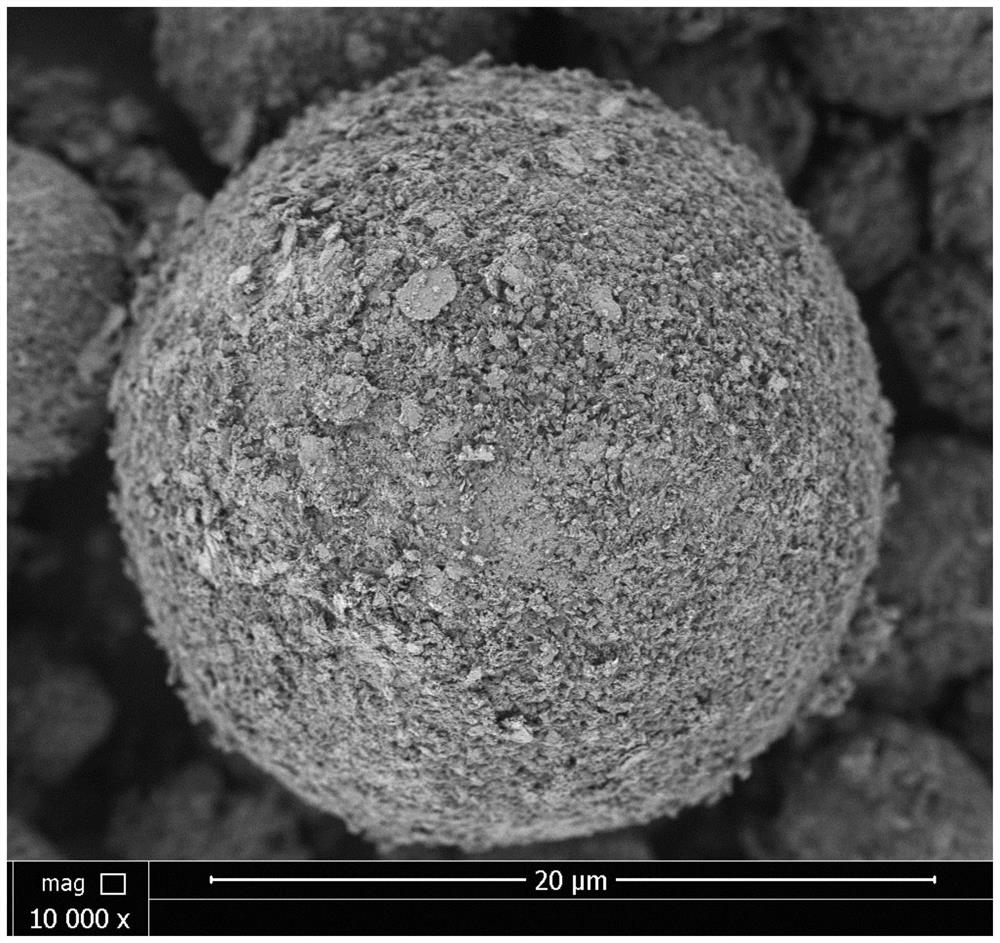

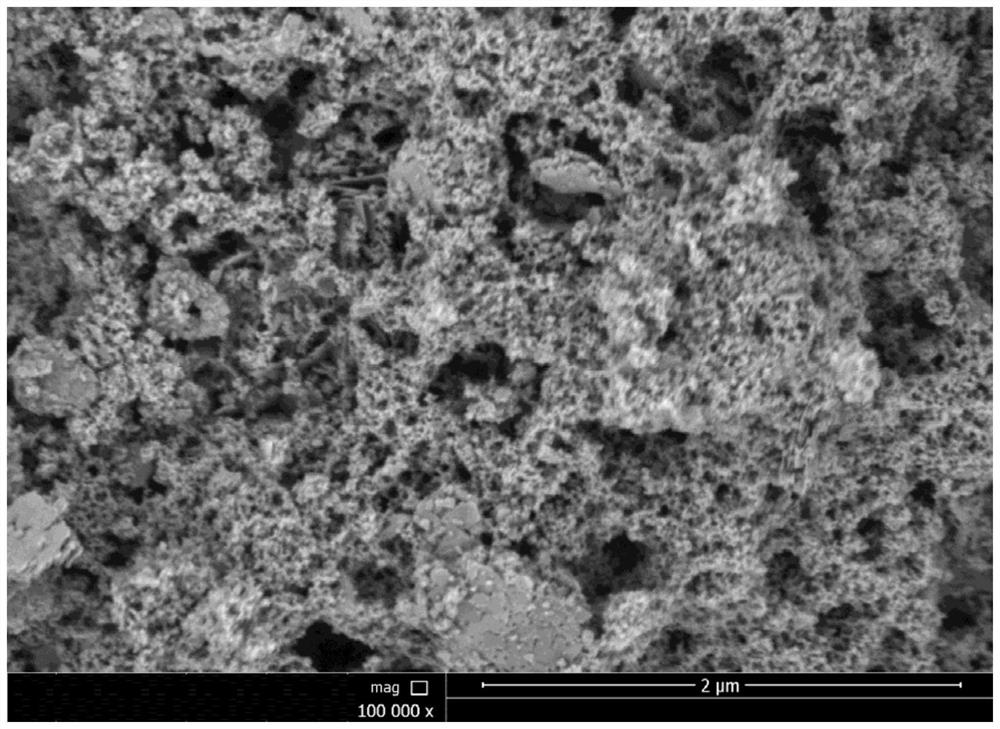

Image

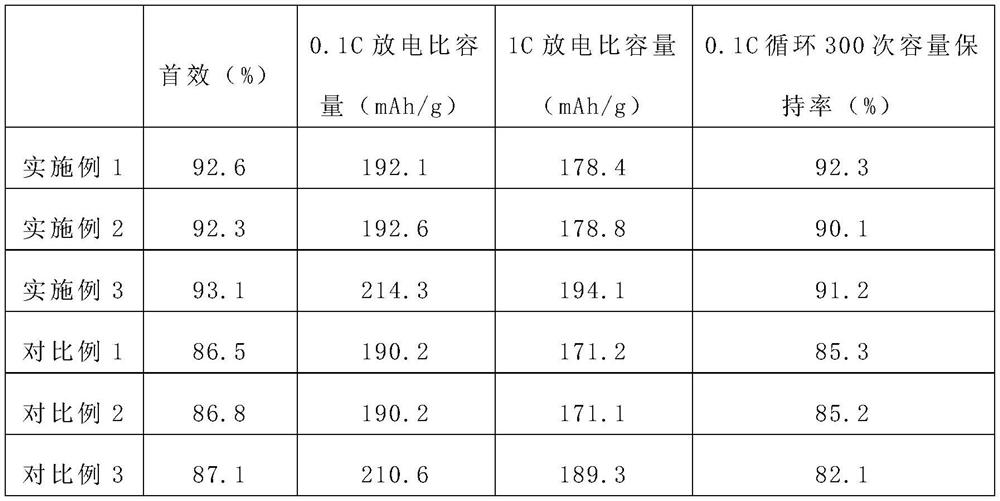

Examples

Embodiment 1

[0047] A method for tin-based coating of a positive electrode material precursor, comprising the following steps:

[0048] S1. prepare a stannous chloride solution with a concentration of 0.5 mol / L;

[0049] S2. prepare the mixed solution of sodium carbonate and sodium sulfide, wherein the sodium carbonate concentration is 0.5mol / L, and the sodium sulfide concentration is 0.5mol / L;

[0050] S3. The nickel cobalt manganese hydroxide (molecular formula: Ni 0.62 Mn 0.2 Co 0.18 (OH) 2 ) is added to the mixed solution prepared in step (2) according to the solid-to-liquid ratio 1g:3mL;

[0051] S4. under the constant stirring that the stirring speed is 300r / min, the stannous chloride solution prepared in step (1) is added dropwise to the mixed solution, and the dropping rate is 35mL / h;

[0052] S5. When it is detected that the pH of the mixed solution is 8-9, the reaction is stopped, and solid-liquid separation is carried out to obtain a wet material;

[0053] S6. According to...

Embodiment 2

[0058] A method for tin-based coating of a positive electrode material precursor, comprising the following steps:

[0059] S1. prepare a stannous chloride solution with a concentration of 0.01 mol / L;

[0060] S2. prepare a mixed solution of sodium carbonate and sodium sulfide, wherein the sodium carbonate concentration is 0.1 mol / L, and the sodium sulfide concentration is 0.1 mol / L;

[0061] S3. The hydroxide of nickel cobalt manganese (molecular formula: Ni 0.62 Mn 0.2 Co 0.18 (OH) 2 ) is added to the mixed solution prepared in step (2) according to the solid-to-liquid ratio 1g:1mL;

[0062] S4. Under the constant stirring that the stirring speed is 200r / min, the stannous chloride solution prepared in step (1) is added dropwise to the mixed solution, and the dropping rate is 25mL / h;

[0063] S5. When it is detected that the pH of the mixed solution is 8-9, the reaction is stopped, and solid-liquid separation is carried out to obtain a wet material;

[0064] S6. Accordin...

Embodiment 3

[0069] A method for tin-based coating of a positive electrode material precursor, comprising the following steps:

[0070] S1. prepare a stannous sulfate solution with a concentration of 1 mol / L;

[0071] S2. prepare the mixed solution of sodium carbonate and sodium sulfide, wherein the sodium carbonate concentration is 1.0mol / L, and the sodium sulfide concentration is 1.0mol / L;

[0072] S3. The hydroxide of nickel cobalt manganese (molecular formula: Ni 0.85 Mn 0.08 Co 0.7 (OH) 2 ) is added to the mixed solution prepared in step (2) according to the solid-to-liquid ratio 1g:5mL;

[0073] S4. Under the constant stirring that the stirring speed is 500r / min, the stannous sulfate solution prepared in step (1) is added dropwise to the mixed solution, and the dropping rate is 50mL / h;

[0074] S5. When it is detected that the pH of the mixed solution is 8-9, the reaction is stopped, and solid-liquid separation is carried out to obtain a wet material;

[0075] S6. According to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com