Image sensor forming method and image sensor

A technology of image sensor and photosensitive area, which is applied in the field of image sensor formation and image sensor, which can solve the problems of difficult isolation, high electric field strength, and difficult extraction, and achieve the effect of reducing complicated procedures, uniform electric field distribution, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

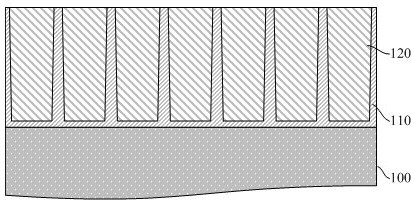

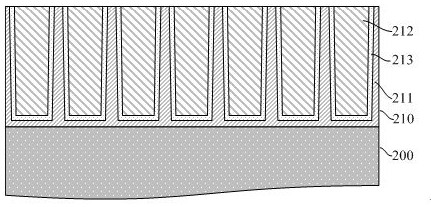

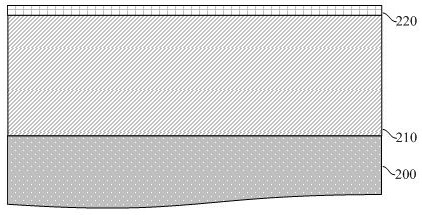

[0085] The invention provides a method for forming an image sensor. The lateral PN junction is formed by means of etching and epitaxy, and an isolation region and a photosensitive region are formed on a semiconductor substrate.

[0086] In an embodiment of an image sensor forming method of the present invention, the following steps are included:

[0087] Step S110: Before forming the gate of the image sensor, a first lateral PN junction is formed by at least one etching process and at least one epitaxy process.

[0088] The formed first lateral PN junction is used for isolation between each pixel unit of the image sensor. Wherein, the present invention does not limit the sequence and specific times of the epitaxy process in the etching process, but in the process of forming the image sensor under the idea of the present invention, at least one etching process and one epitaxy process are required to form the image sensor. The lateral PN junction, that is, the PN junction bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com