Split type heat dissipation bearing seat with overheating prevention function

A split type, bearing seat technology, applied in the direction of shaft and bearing, bearing cooling, bearing components, etc., can solve the problems of dust damage, lack of shaft shaking, effective suppression of operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

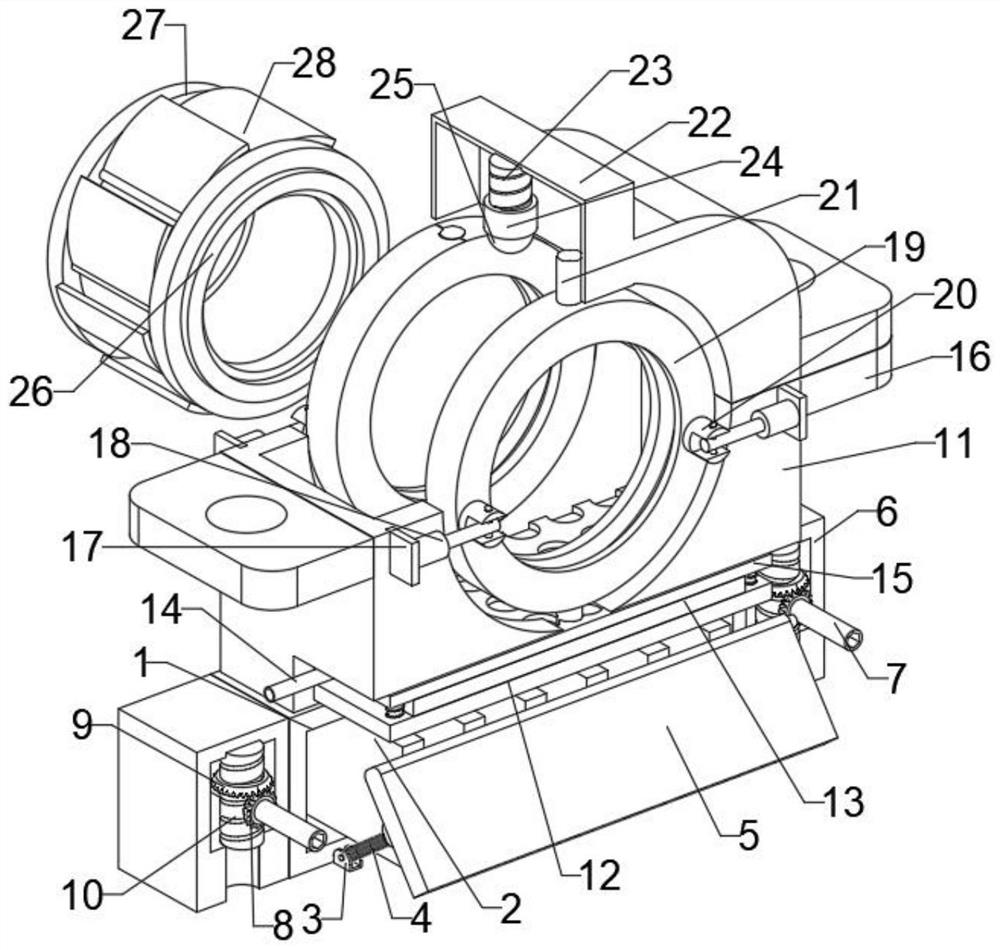

[0033] Please refer to Figure 1 to Figure 10 :

[0034] The present invention proposes a split heat dissipation bearing seat with overheating prevention, including: a base 1, the main body of the base 1 is a box structure, and the interior of the base 1 is installed in a linear array with heat sinks 2, and the interior of the base 1 is fixedly connected with a mounting seat 3. A temperature sensing tube 4 is hinged inside the mounting base 3. The temperature sensing tube 4 is a telescopic structure, and the interior of the temperature sensing tube 4 is filled with thermal expansion liquid. The front and rear sides of the base 1 are hinged with baffles 5. The baffles 5 together form a closed structure. The inner bottom end surface of the support base B22 is provided with an adjusting rod 23. The adjusting rod 23 is a screw rod structure, and the bottom side of the adjusting rod 23 is screwed to the buzzer 24, and the bottom of the buzzer 24 is screwed. A pressure sensor 25 is...

no. 2 example

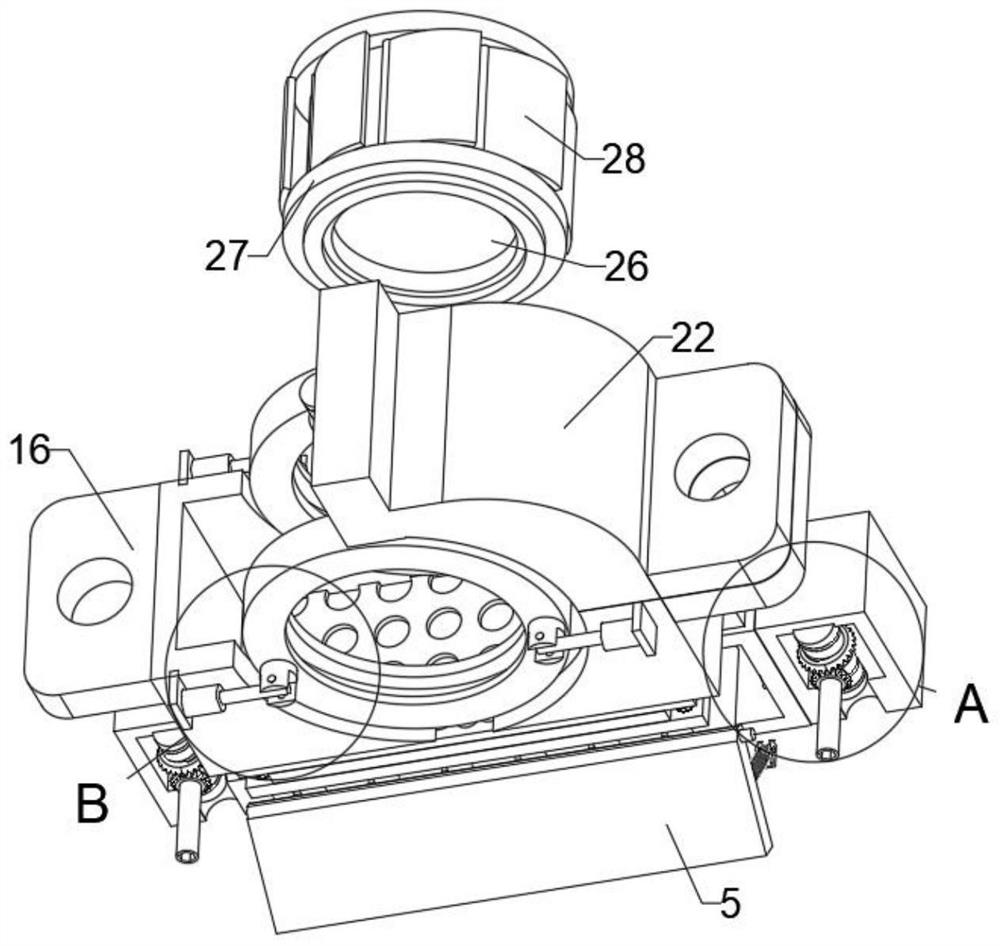

[0043] Based on the split-type heat dissipation bearing seat with overheating prevention provided by the first embodiment, the mounting block 6 , the clamping rod 7 , the helical gear A8 , the helical gear B9 and the ejector rod 10 can realize the installation seat 3 in a relatively narrow space. The internal quick assembly operation is carried out, but in practical application, it is still impossible to quickly inject grease into the bearing seat and the inside of the bearing for lubricating operation when the bearing seat is in use, and there are limitations. In order to solve the above problems, The device is also provided with a base 1, a heat sink 2, a mounting seat 3, a temperature sensing tube 4, a baffle 5, a support seat A11, a bottom plate 12, a liquid storage bag 13, a connecting pipe 14 and a spray plate 15. The heat sink 2 in the base 1 introduces the excessive temperature into the liquid in the temperature sensing tube 4 through the heat-conducting metal, so that ...

no. 3 example

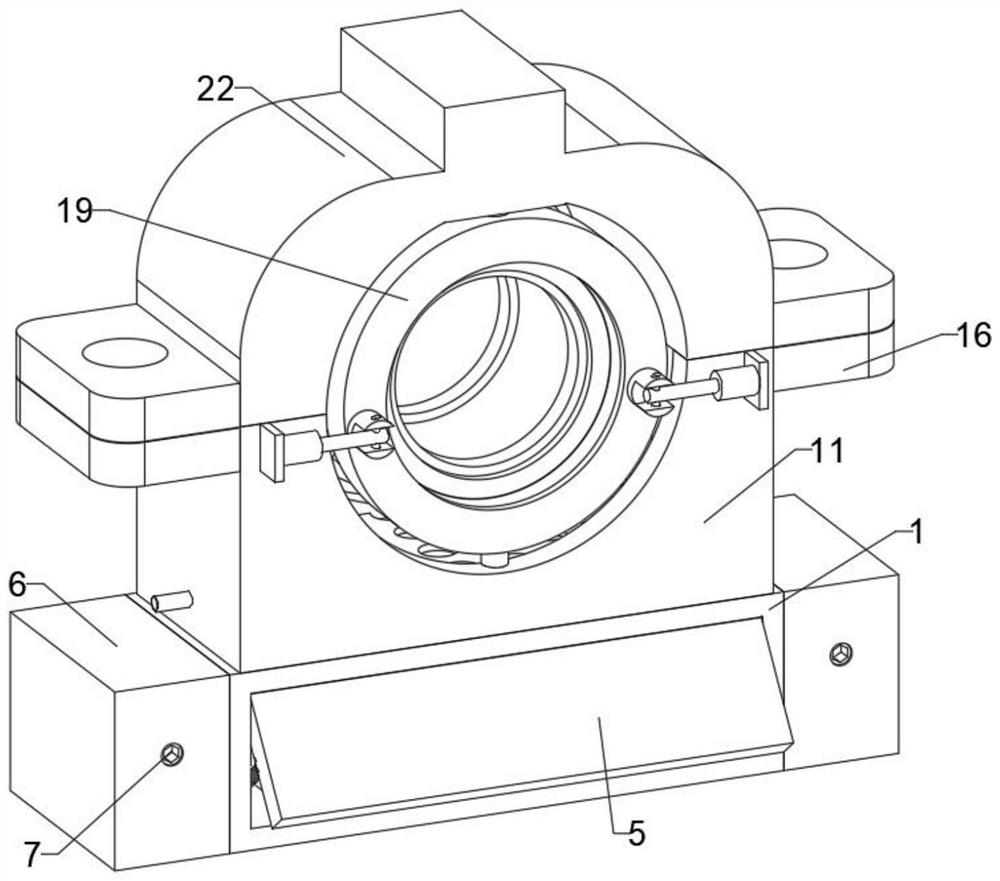

[0053] Based on the split heat dissipation bearing seat with overheating prevention provided by the second embodiment, the base 1 , the heat sink 2 , the mounting seat 3 , the temperature sensing tube 4 , the baffle 5 , the support seat A11 , the bottom plate 12 , and the liquid storage bag 13 are used. , Take over 14 and spray plate 15 can realize fast automatic lubrication operation, but it still cannot realize automatic detection and traction operation of the drive shaft in practical application, and it is easy to cause damage to the bearing seat due to the deflection of the drive shaft , in order to solve the above problems, the device is also provided with a side plate 17, a traction push rod 18, a bearing seat 19, a limit seat 20, a connecting rod 21, a support seat B22, an adjustment rod 23, a buzzer 24, and a pressure sensor 25. , inner ring 26 , guide ring 27 and guide plate 28 .

[0054] Furthermore, according to embodiments of the present invention, such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com