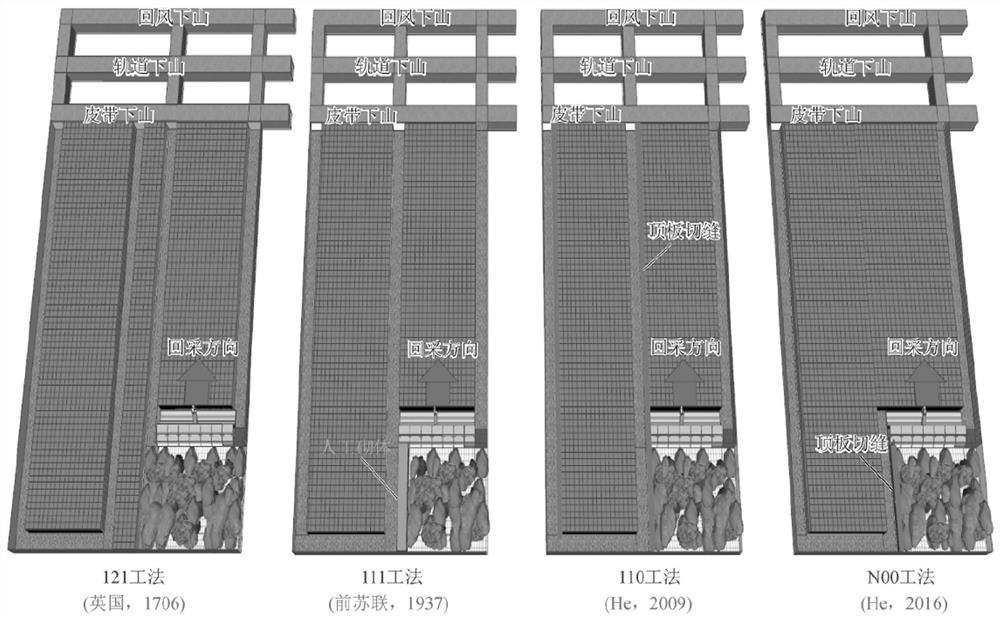

Thin coal seam N00 construction method mining, cutting and anchoring system

A thin coal seam and construction method technology, applied in the field of thin coal seam N00 construction method mining and cutting anchor system, can solve the problems of unfavorable roadway and rapid roadway formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

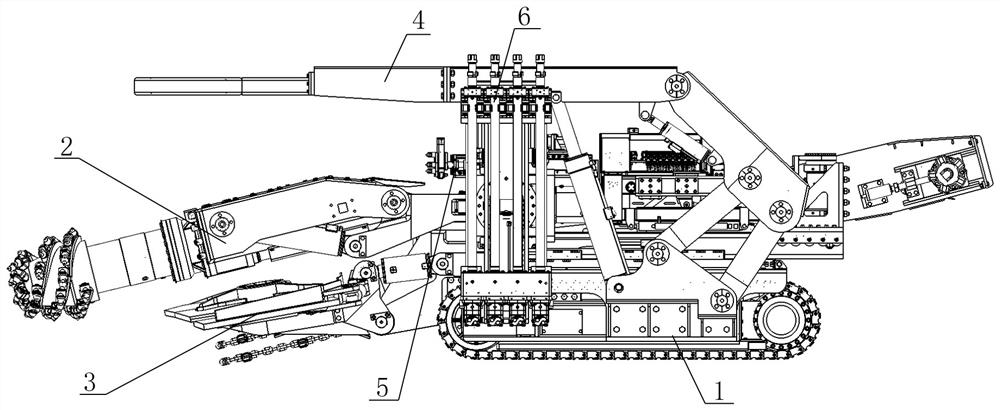

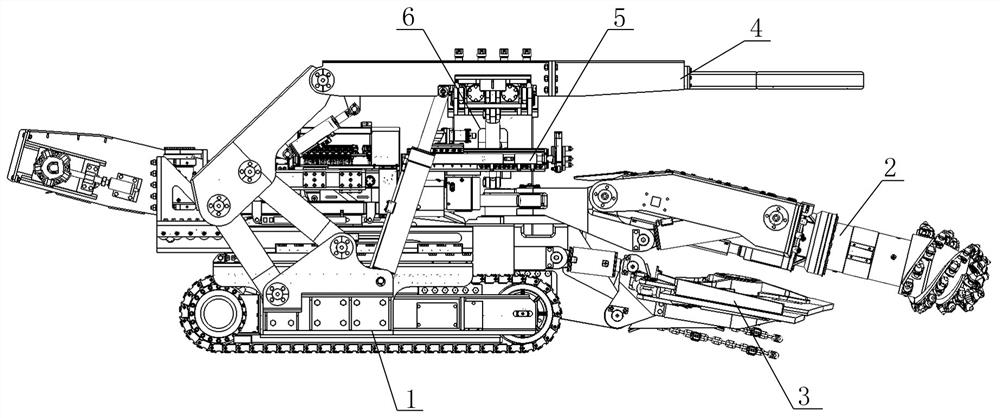

[0041] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0042] like Figure 2 to Figure 8 As shown, the front view, rear view, left view, right view, top view, bottom view and three-dimensional view of the thin coal seam N00 method mining and cutting anchor system of the present invention are respectively given. The cutting mechanism 2, the shovel plate mechanism 3, the supporting mechanism 4, the bolt mechanism 5, the slitting mechanism 6 and the transport mechanism 7 are constituted. , the shovel plate mechanism 3 is located below the cutting mechanism 2, and is used to collect the falling coal mines. The support mechanism 4 is located above the traveling mechanism 1, and is used to temporarily support the support belt supporting the top wall and / or side wall of the roadway. The number of bolt mechanisms 5 is two, and two bolt mechanisms 5 are provided. The two sides above the traveling mechanism are used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com