Light-resistant thermochromic fabric and preparation method thereof

A temperature-induced discoloration and fabric technology, applied in the field of material science, can solve the problems of poor light fatigue resistance, high technical requirements, and fading of microcapsules, and achieve the effect of good ultraviolet absorption performance, broad application prospects, and slow color fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

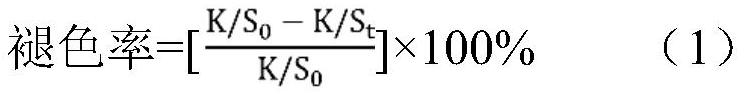

Image

Examples

Embodiment 1

[0042] A method for preparing light-resistant thermochromic fabric, comprising the steps of:

[0043] (1) Preparation of UV-absorbing polymers:

[0044] 24.924g methyl methacrylate and 1.876g 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2-methacrylate (the mass ratio of the two is 93 : 7) Dissolved in 40 g of toluene, and slowly added dropwise 0.32 g of benzoyl peroxide, then heated to 80 ° C, and reacted for 5 h, after the reaction was completed, the product was extracted with methanol, and dried to obtain a UV-absorbing polymer;

[0045] (2) Preparation of thermochromic fabric:

[0046] Mix 10g of blue thermochromic dye (fluoran dye, the discoloration temperature is 30°C), 15g of printing adhesive DM-5128, 22g of water and 3g of thickener DM-5221G, and then stir until viscous to obtain a printing paste; Evenly apply 8g printing paste to 100cm 2On cotton fabrics, thermochromic fabrics were obtained after baking at 120°C for 10 minutes;

[0047] (3) Preparation of lig...

Embodiment 2

[0050] Adjust 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2-methacrylate in step (1) of Example 1 to 2-hydroxy-4-allyl Oxybenzophenone; adjust the blue thermochromic dye in step (2) of Example 1 to be a red thermochromic dye (fluoran dye, the discoloration temperature is 30°C), and the others are consistent with those in Example 1, to obtain the lightfast thermochromic fabric.

Embodiment 3

[0052] Adjust 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl]ethyl 2-methacrylate in step (1) of Example 1 to 2-hydroxy-4-propene base benzophenone; others are the same as those in Example 1, and the light-resistant thermochromic fabric is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com