Preparation method of large-diameter 6061 aluminum alloy extruded pipe for hydrogen storage of new energy automobile

A new energy vehicle and aluminum alloy technology, which is applied in the field of aluminum alloy profile processing, can solve the problems such as the inability to meet the technical requirements of lightweight and high hydrogen storage density of new energy vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of large-diameter 6061 aluminum alloy extruded pipe for large-diameter new energy vehicles, the state and specifications of the product are shown in Table 1,

[0034]

[0035] Including the following process flow:

[0036] (1) Alloy composition optimization: optimize the Mg / Si ratio and the ratio of other alloying elements in 6061 aluminum alloy, and control the content of impurity elements, in terms of weight percentage, among which: Si0.65%, Fe0.18%, Cu0.3 %, Mn0.15%, Mg0.86%, Zn0.18%, Ti0.14%, Cr0.17%, Ni0.05%, the balance is Al, the content of Pb and Bi≤0.003%;

[0037] (2) Smelting: Select high-purity ingots of various other alloying elements, metal additives and intermediate alloys, and then put them into an electric furnace with a furnace temperature of 900 °C, the melting temperature is 725 °C, and the temperature to be smelted to 730 °C When slag removal, magnesium ingots and various additives are added, the magnesium ingots must be add...

Embodiment 2

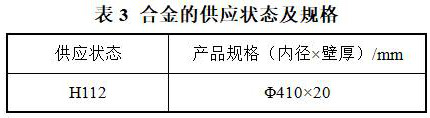

[0049] A preparation method of large-diameter 6061 aluminum alloy extruded pipe for large-diameter new energy vehicles, the state and specifications of the product are shown in Table 3:

[0050]

[0051] Including the following process flow:

[0052] (1) Alloy composition optimization: optimize the Mg / Si ratio and the ratio of other alloying elements in 6061 aluminum alloy, and control the content of impurity elements, in terms of weight percentage, among which: Si0.60%, Fe0.16%, Cu0.3 %, Mn0.17%, Mg0.90%, Zn0.20%, Ti0.15%, Cr0.18%, Ni0.05%, the content of Pb and Bi is ≤0.003, and the balance is Al;

[0053] (2) Smelting: Select high-purity ingots of various other alloying elements, metal additives and intermediate alloys, and then put them into an electric furnace with a furnace temperature of 900 °C, the melting temperature is 735 °C, and the temperature to be smelted to 730 °C When slag removal, magnesium ingots and various additives are added, the magnesium ingots must...

Embodiment 3

[0065] A preparation method of large-diameter 6061 aluminum alloy extruded pipe for large-diameter new energy vehicles, the state and specifications of the product are shown in Table 5:

[0066]

[0067] Including the following process flow:

[0068] (1) Alloy composition optimization: optimize the Mg / Si ratio and the ratio of other alloying elements in 6061 aluminum alloy, and control the content of impurity elements, in terms of weight percentage, among which: Si0.69%, Fe0.19%, Cu0.35 %, Mn0.20%, Mg0.90%, Zn0.25%, Ti0.15%, Cr0.18%, Ni0.05%, the content of Pb and Bi is ≤0.003, and the balance is Al;

[0069] (2) Smelting: Select high-purity ingots of various other added alloying elements, metal additives and intermediate alloys, and then put them into an electric furnace with a furnace temperature of 890 °C, the melting temperature is 735 °C, and the temperature to be smelted to 730 °C When slag removal, magnesium ingots and various additives are added, the magnesium ingo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com