Method for improving quality of pyrolytic oil by pretreating biomass raw material by using freeze-thaw assisted low cosolvent and application of method

A technology for pretreatment of biomass and biomass raw materials, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, special forms of dry distillation, etc., to achieve the effects of enrichment, simple operation and improvement of pyrolysis oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

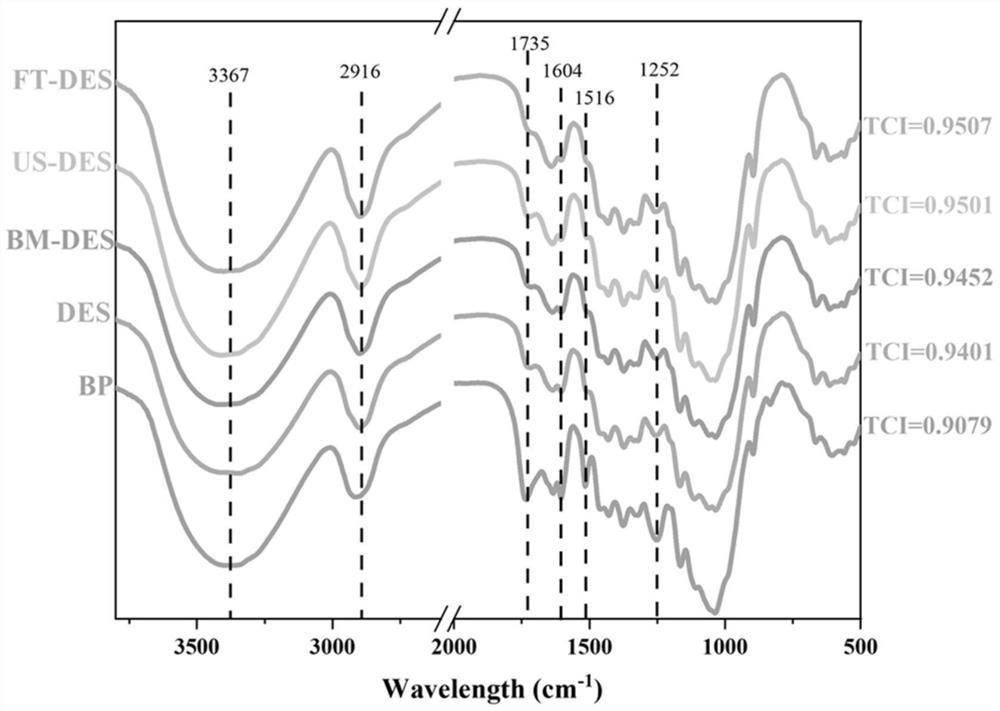

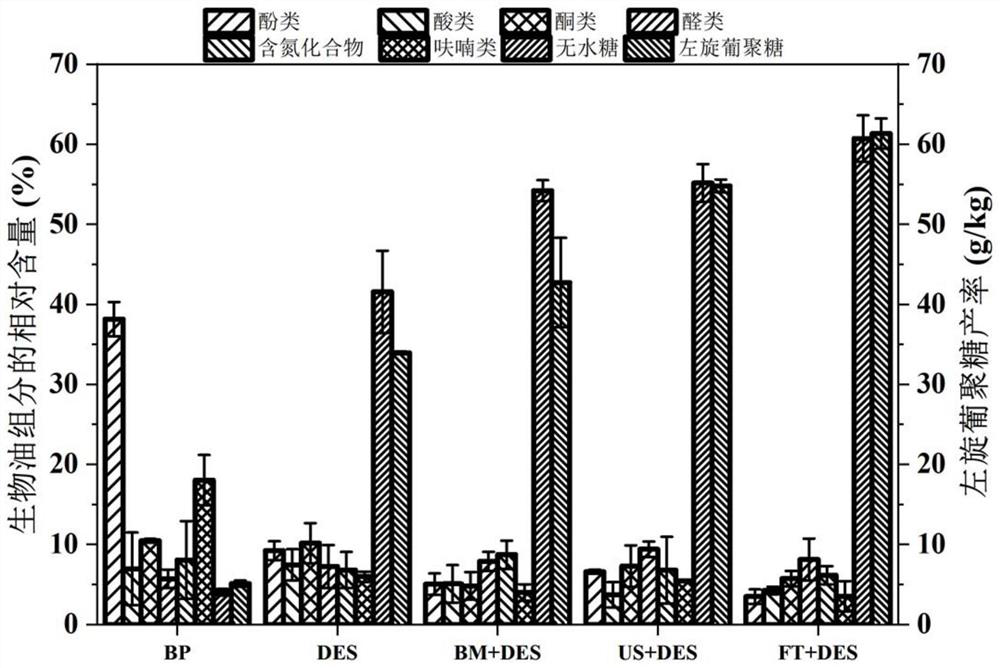

Method used

Image

Examples

Embodiment 1

[0053] (1) Freeze-thaw (FT) pretreatment of bagasse raw materials: mix bagasse powder (BP) and distilled water at a ratio of 1:15 (g / mL) solid-liquid ratio, place them in a centrifuge tube, and continuously shake (300r / mL) min stirring 5min) to promote the uniform dispersion of bagasse in water. Then, the centrifuge tube containing the bagasse solution was hoisted into a liquid nitrogen tank (-196° C.) and frozen for 1 hour. After the freezing time, the centrifuge tube was taken out and thawed at room temperature. Finally, the freeze-thawed bagasse was vacuum filtered and washed with (50%, v / v) alcohol solution until the filtrate was colorless and transparent, and dried in an oven at 105° C. for 24 hours.

[0054] (2) Preparation of imidazole-deep eutectic solvent system: Weigh 39.50 g of imidazole and 40.50 g of choline chloride in a thick-walled pressure bottle, place them in an oil bath at 125°C, heat and stir at 300 r / min The speed reaction was carried out for 30 min unti...

Embodiment 2

[0058] (1) Freeze-thaw pretreatment of bagasse raw materials: mix bagasse powder (BP) and distilled water in a ratio of 1:15 (g / mL) solid-liquid ratio, place in a centrifuge tube, and continuously shake (300r / min for 5min) ) to promote the uniform dispersion of bagasse in water. Then, the centrifuge tube containing the bagasse solution was hoisted into a liquid nitrogen tank (-196° C.) and frozen for 2 hours. After the freezing time, the centrifuge tube was taken out and thawed at room temperature. Finally, the freeze-thawed bagasse was vacuum filtered and washed with (50%, v / v) alcohol solution until the filtrate was colorless and transparent, and dried in an oven at 105° C. for 24 hours.

[0059] (2) Preparation of imidazole-deep eutectic solvent system: Weigh 39.50 g of imidazole and 40.50 g of choline chloride in a thick-walled pressure bottle, place them in an oil bath at 125°C, heat and stir at 300 r / min The speed reaction was carried out for 30 min until the mixed reag...

Embodiment 3

[0063] (1) Freeze-thaw pretreatment of bagasse raw materials: mix bagasse powder (BP) and distilled water at a ratio of 1:15 (g / mL) solid-liquid ratio and place them in a centrifuge tube, then add 30 mL of distilled water, and shake continuously ( 300r / min stirring for 5min) to promote the uniform dispersion of bagasse in water. Then, the centrifuge tube containing the bagasse solution was hung into a liquid nitrogen tank (-196° C.) and frozen for 3 hours. After the freezing time, the centrifuge tube was taken out and thawed at room temperature. Finally, the freeze-thawed bagasse was vacuum filtered and washed with (50%, v / v) alcohol solution until the filtrate was colorless and transparent, and dried in an oven at 105° C. for 24 hours.

[0064] (2) Preparation of imidazole-deep eutectic solvent system: Weigh 39.50 g of imidazole and 40.50 g of choline chloride in a thick-walled pressure bottle, place them in an oil bath at 125°C, heat and stir at 300 r / min The speed reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com