Thin, transparent and flash anti-shrinkage top-coat as well as preparation method and use method of thin, transparent and flash anti-shrinkage top-coat

An anti-shrinkage, clear topcoat technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor stability, affecting transparency and gloss retention, organic matter escape, etc., to achieve excellent gloss and hardness, Excellent transparency and gloss retention, environmental protection and health optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

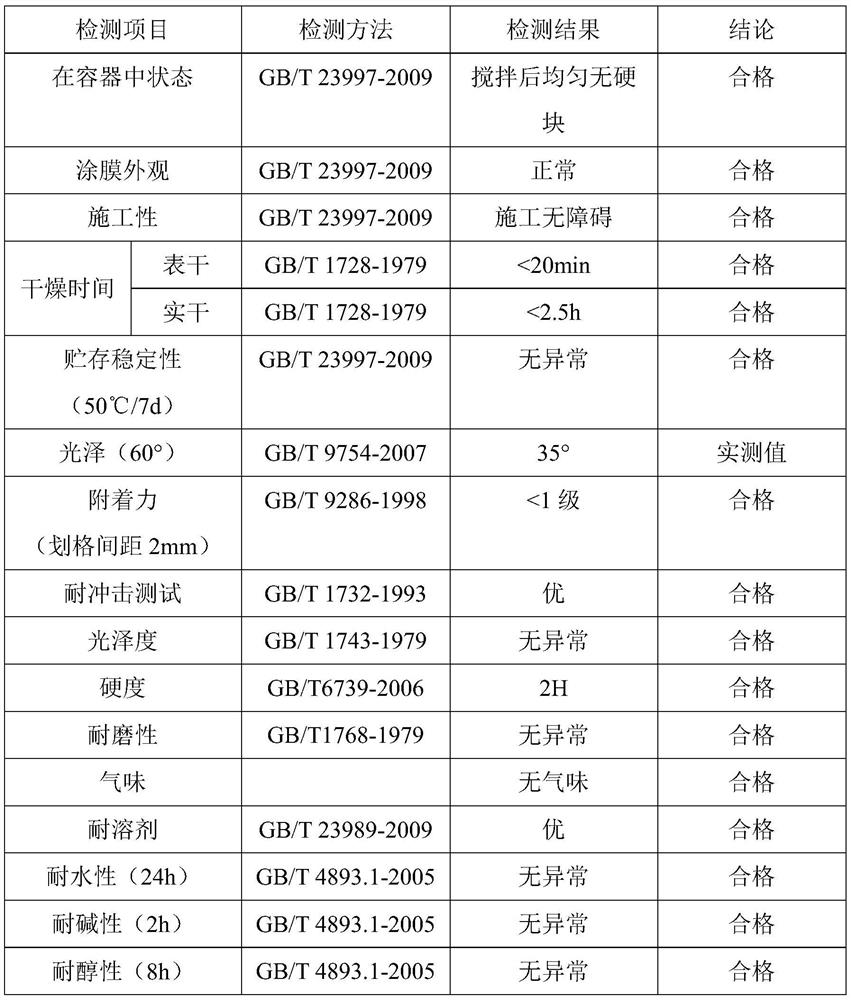

Examples

Embodiment 1

[0072] A thin, transparent, anti-shrinkage clear topcoat, the preparation raw materials include A component and B component, and the weight ratio of A component and B component is 1:0.5;

[0073] The raw materials for the preparation of the A component, by weight percentage, include: 40% of acrylic resin, 20% of cellulose organic acid ester, 12% of auxiliary agents, 3% of fillers, and solvent supplementary balance to 100%.

[0074] The raw materials for the preparation of the B component, in terms of weight percentage, include: 30% solvent, 0.5% dehydrating agent, and curing agent supplementary balance to 100%.

[0075] Described acrylic resin is hydroxy acrylic resin, model 7313-1-60, purchased from Changxing, Taiwan, China;

[0076] Described cellulose organic acid ester is cellulose acetate;

[0077] The filler is silica, the porosity of the silica is 1.8mL / g, model: ED-2, purchased from Grace Company;

[0078] The auxiliary agent includes a dispersant, a defoaming agent,...

Embodiment 2

[0095] A thin, transparent, anti-shrinkage clear topcoat, the preparation raw materials include A component and B component, and the weight ratio of A component and B component is 1:0.5;

[0096] The raw materials for the preparation of the A component, by weight percentage, include: 35% of alkyd resin, 15% of cellulose organic acid ester, 8% of auxiliary agents, 3% of fillers, and solvent supplementary balance to 100%.

[0097] The raw materials for the preparation of the B component, in terms of weight percentages, include: 25% solvent, 0.2% dehydrating agent, and curing agent supplementary balance to 100%.

[0098] Described alkyd resin model 3807-B-65 was purchased from Changxing, Taiwan, China;

[0099] Described cellulose organic acid ester is cellulose acetate;

[0100] The filler is silica, the porosity of the silica is 1.8mL / g, model: ED-2, purchased from Grace Company;

[0101] The auxiliary agent includes a dispersant, a defoaming agent, a leveling agent, and a ha...

Embodiment 3

[0115] A thin, transparent, anti-shrinkage clear topcoat, the preparation raw materials include A component and B component, and the weight ratio of A component and B component is 1:0.2;

[0116] The raw materials for the preparation of the A component, by weight percentage, include: 45% of acrylic resin, 25% of cellulose organic acid ester, 15% of auxiliary agents, 8% of fillers, and solvent supplementary balance to 100%.

[0117] The raw materials for the preparation of the B component, in terms of weight percentage, include: 35% solvent, 0.8% dehydrating agent, and curing agent supplementary balance to 100%.

[0118] Described acrylic resin is hydroxy acrylic resin, model 7313-1-60, purchased from Changxing, Taiwan, China;

[0119] Described cellulose organic acid ester is cellulose acetate;

[0120] The filler is silica, the porosity of the silica is 1.8mL / g, model: ED-2, purchased from Grace Company;

[0121] The auxiliary agent includes a dispersant, a defoamer, a leve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com