Polyether-ether-ketone multi-element nano lubricating composite material as well as preparation method and application thereof

A technology of polyether ether ketone and composite materials, which is applied in the field of solid lubrication of composite materials, can solve problems such as weak bonding force of friction pairs, difficult lubrication effect, poor matrix compatibility, etc., achieve good mechanical properties, reduce friction coefficient and wear rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Preparation of silver-loaded hexagonal boron nitride nanosheets:

[0070] S1-1: Weigh 10g of hexagonal boron nitride nanosheets and 10g of sodium oleate respectively, add them into 500ml of dimethylformamide, and ultrasonically disperse for 30min to obtain a dispersion;

[0071] S1-2: Weigh 5 mol of AgNO prepared with a mass fraction of 10% 3 The solution was added to the dispersion obtained by 10 g of S1-1, and then ultrasonically dispersed for 90 min to obtain a dispersion;

[0072] S1-3: The dispersion obtained in step S1-2 is heated at 40° C. for 1 h. After the reaction, the precipitate is collected by filtration, washed, and dried to obtain silver-loaded hexagonal boron nitride nanosheets, which are marked as Ag / BN.

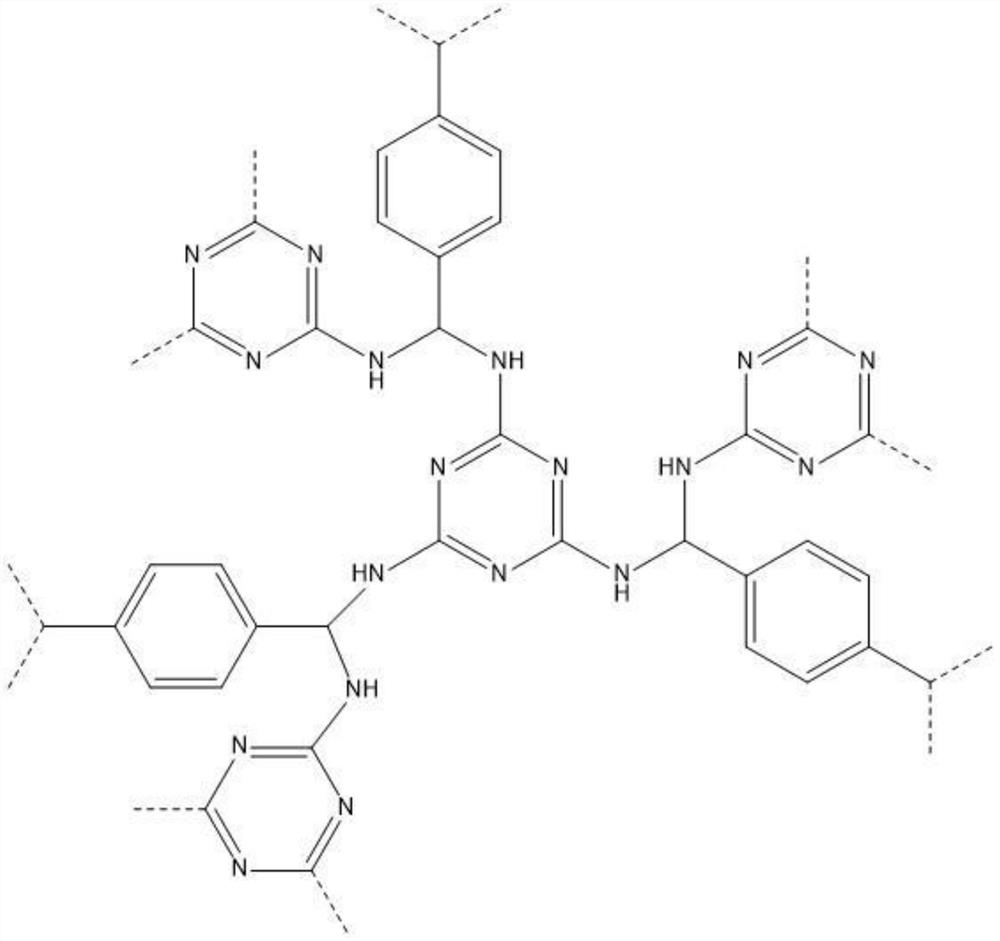

[0073] (2) Preparation of Ag / BN modified by covalent organic framework nanomaterials (COF)

[0074] 100g of COF and 50g of Ag / BN were added to isopropanol, then ultrasonicated for 30min to obtain a dispersion, the dispersion was centrifuged to c...

Embodiment 2

[0080] (1) Preparation of silver-loaded hexagonal boron nitride nanosheets:

[0081] S1-1: Weigh 15g of hexagonal boron nitride nanosheets and 18g of sodium oleate respectively, add them into 500ml of dimethylformamide, and ultrasonically disperse for 50min to obtain a dispersion;

[0082] S1-2: Weigh 10 mol of AgNO prepared with a mass fraction of 10% 3 The solution was added to the dispersion obtained by 10g of S1, and then ultrasonically dispersed for 90min to obtain a dispersion;

[0083] S1-3: The dispersion obtained in step S1-2 is heated at 50° C. for 1 h. After the reaction, the precipitate is collected by filtration, washed, and dried to obtain silver-loaded hexagonal boron nitride nanosheets, which are labeled as Ag / BN.

[0084] (2) Preparation of Ag / BN modified by covalent organic framework nanomaterials (COF)

[0085] 100g of COF and 70g of Ag / BN were added to isopropanol, then ultrasonicated for 40min to obtain a dispersion, the dispersion was centrifuged to col...

Embodiment 3

[0092] (1) Preparation of silver-loaded hexagonal boron nitride nanosheets:

[0093] S1-1: Weigh 20g of hexagonal boron nitride nanosheets and 18g of sodium oleate respectively, add them into 600ml of dimethylformamide, and ultrasonically disperse for 70min to obtain a dispersion;

[0094] S1-2: Weigh 20mol of AgNO prepared with a mass fraction of 10% 3 The solution was added to the dispersion obtained by 10g of S1, and then ultrasonically dispersed for 90min to obtain a dispersion;

[0095] S1-3: The dispersion obtained in step S1-2 was heated at 50° C. for 2 h, and after the reaction was completed, the precipitate was collected by filtration, washed, and dried to obtain silver-loaded hexagonal boron nitride nanosheets, marked as Ag / BN.

[0096] (2) Preparation of Ag / BN modified by covalent organic framework nanomaterials (COF)

[0097] 100g of COF and 80g of Ag / BN were added to isopropanol, then ultrasonicated for 50min to obtain a dispersion, the dispersion was centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com