Mass concrete and preparation method thereof

A technology of mass concrete and machine-made sand, which is applied in the field of concrete preparation to achieve the effect of shortening the transmission path, reducing the temperature difference and enhancing the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

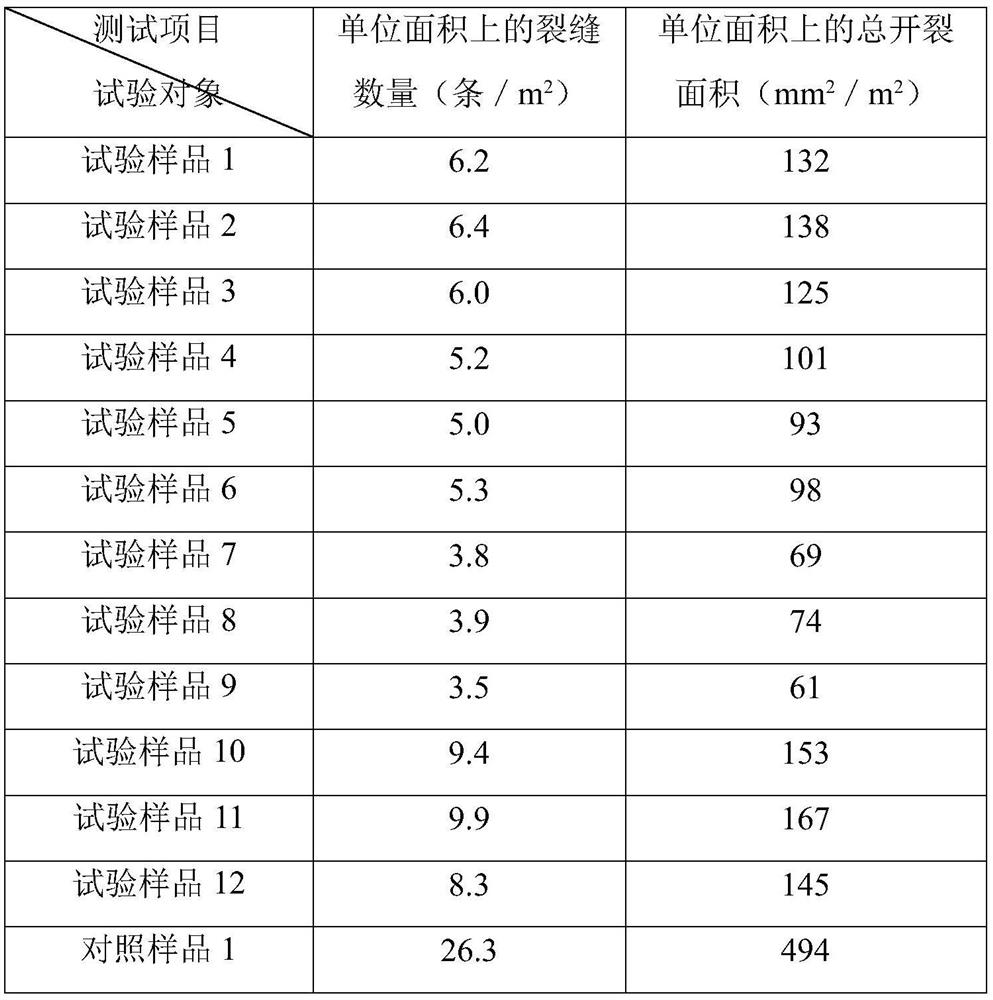

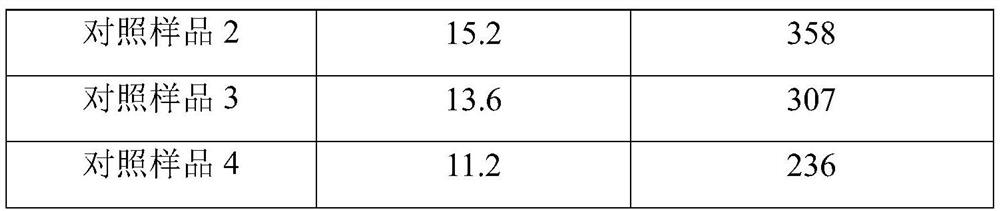

Examples

Embodiment 1

[0046] A mass concrete is made from the following raw materials by weight:

[0047] 27kg of cement, 85kg of machine-made sand, 95kg of crushed stone, 12kg of fly ash, 5.0kg of mineral powder, 1.0kg of water reducing agent, 2.0kg of thermally conductive silica gel powder, 1.5kg of lithium carbonate solution and 15kg of water; the particle size of thermally conductive silica gel powder is 20um; The lithium carbonate solution is a saturated solution at a temperature of 25°C, and the mass fraction of the lithium carbonate solution is 25.7%.

[0048] Mass concrete is prepared by the following steps:

[0049] S1: Mix cement, machine-made sand, crushed stone, fly ash, mineral powder, thermally conductive silica gel powder and water, and stir for 30s to obtain a ready-mixed mixture;

[0050] S2: Mix the water reducing agent, the lithium carbonate solution and the ready-mixed mixture, and stir for 90s to obtain mass concrete.

Embodiment 2

[0052] A mass concrete is made from the following raw materials by weight:

[0053] 30kg of cement, 89kg of machine-made sand, 93kg of crushed stone, 11kg of fly ash, 4.0kg of mineral powder, 0.9kg of water reducing agent, 2.3kg of thermally conductive silica gel powder, 1.8kg of lithium sulfate solution and 16kg of water; the particle size of thermally conductive silica gel powder is 35um; The lithium sulfate solution is a saturated solution at a temperature of 25°C, and the mass fraction of the lithium sulfate solution is 25.7%.

[0054] Mass concrete is prepared by the following steps:

[0055] S1: Mix cement, machine-made sand, crushed stone, fly ash, mineral powder, thermally conductive silica gel powder and water, and stir for 45s to obtain a ready-mixed mixture;

[0056] S2: Mix the water reducing agent, the lithium sulfate solution and the ready-mixed mixture, and stir for 80s to obtain mass concrete.

Embodiment 3

[0058] A mass concrete is made from the following raw materials by weight:

[0059] 32kg of cement, 92kg of machine-made sand, 90kg of crushed stone, 10kg of fly ash, 3.0kg of mineral powder, 0.8kg of water reducing agent, 2.5kg of thermally conductive silica gel powder, 2.0kg of lithium carbonate solution and 18kg of water; the particle size of thermally conductive silica gel powder is 50um; The lithium carbonate solution is a saturated solution at a temperature of 25°C, and the mass fraction of the lithium carbonate solution is 25.7%.

[0060] Mass concrete is prepared by the following steps:

[0061] S1: Mix cement, machine-made sand, crushed stone, fly ash, mineral powder, thermally conductive silica gel powder and water, and stir for 60s to obtain a ready-mixed mixture;

[0062] S2: Mix the water reducing agent, the lithium carbonate solution and the ready-mixed mixture, and stir for 60s to obtain mass concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com