Novel nano calcium silicate hydrate polycarboxylic acid early strength agent and preparation method thereof

A technology of calcium silicate polycarboxylic acid and calcium silicate hydrate, which is applied in the field of concrete admixtures, can solve the problems affecting the early strength and later performance of concrete, particle size and dispersion stability that affect the concrete promotion effect. Reunion and other problems, to shorten the production cycle, the preparation method is simple and feasible, and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

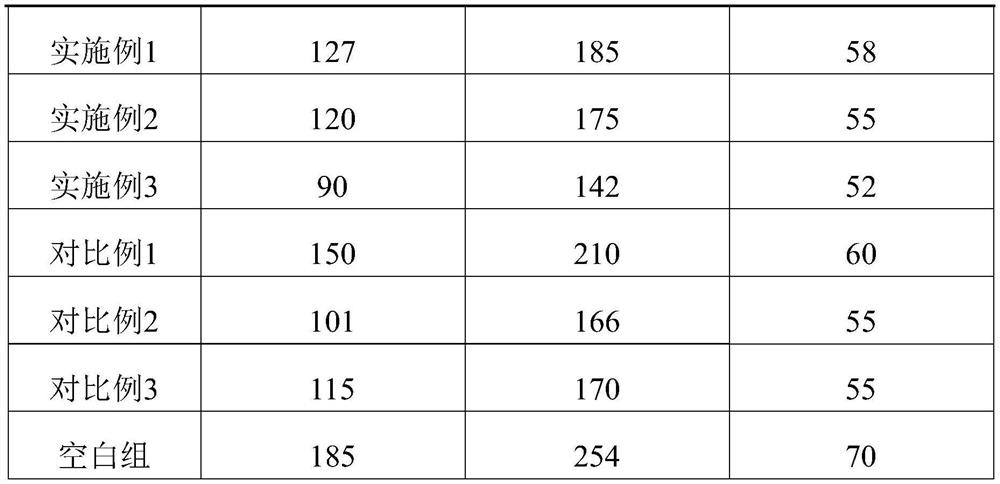

Examples

Embodiment 1

[0026] A preparation method of a novel early-strength agent of nano-calcium silicate hydrate polycarboxylic acid, comprising the following steps:

[0027] (1) Dissolve calcium nitrate tetrahydrate in deionized water, prepare a calcium nitrate solution with a mass percentage concentration of 40%, dissolve sodium silicate nonahydrate in deionized water, and prepare a sodium silicate solution with a mass percentage concentration of 30% , the polycarboxylate water-reducing agent is dissolved in water to make the mass fraction of the polycarboxylate water-reducing agent as 4% of the reaction bottom liquid, and the pH of the reaction bottom liquid is adjusted by sodium hydroxide to 12;

[0028] (2) the reaction bottom liquid obtained in step (1) is added to the reactor, heated to 60° C., then insulation and stirring are carried out, and the stirring speed is 600 rpm, and then calcium nitrate solution and sodium silicate solution are added dropwise simultaneously using a peristaltic p...

Embodiment 2

[0032] A preparation method of a novel early-strength agent of nano-calcium silicate hydrate polycarboxylic acid, comprising the following steps:

[0033](1) Dissolve calcium nitrate tetrahydrate in deionized water, prepare a calcium nitrate solution with a mass percentage concentration of 40%, dissolve sodium silicate nonahydrate in deionized water, and prepare a sodium silicate solution with a mass percentage concentration of 30% , the polycarboxylate water-reducing agent is dissolved in water to make the mass fraction of the polycarboxylate water-reducing agent as 4% of the reaction bottom liquid, and the pH of the reaction bottom liquid is adjusted by sodium hydroxide to 12;

[0034] (2) the reaction bottom liquid obtained in step (1) is added to the reactor, heated to 60° C., then insulation and stirring are carried out, and the stirring speed is 600 rpm, and then calcium nitrate solution and sodium silicate solution are added dropwise simultaneously using a peristaltic pu...

Embodiment 3

[0038] A preparation method of a novel early strength agent of nano calcium silicate hydrate polycarboxylate, comprising the following steps:

[0039] (1) calcium nitrate tetrahydrate is dissolved in deionized water, the preparation mass percentage concentration is 40% calcium nitrate solution, in the calcium nitrate solution, adding quality is the regulator of calcium nitrate quality 0.5%, the regulator is 1 by mass ratio : 2 polyethylene glycol and sodium cocoyl glutamate; dissolving sodium silicate nonahydrate in deionized water, preparing a sodium silicate solution with a mass percentage concentration of 30%, dissolving the polycarboxylate water reducing agent in The mass fraction of the polycarboxylate superplasticizer made in water was 4% of the reaction bottom liquid, and the pH of the reaction bottom liquid was adjusted to 12 by using sodium hydroxide; the polycarboxylate superplasticizer was the same as that in Example 2;

[0040] (2) the reaction bottom liquid obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com