Method for calcining cement clinker by using high-sulfur coal as fuel

A technology for cement clinker and high-sulfur coal is applied in the field of calcined cement clinker to achieve the effects of reducing process accidents and alleviating skin blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

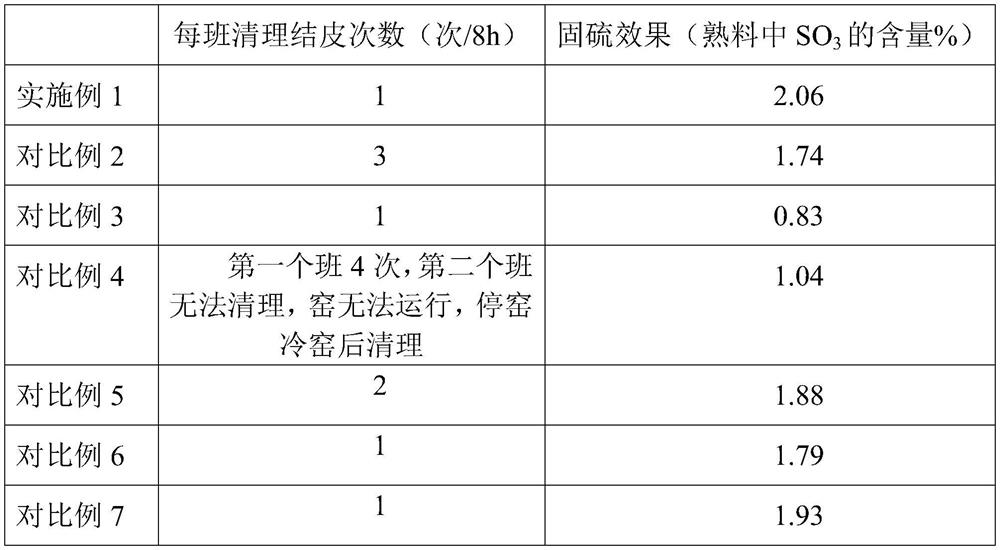

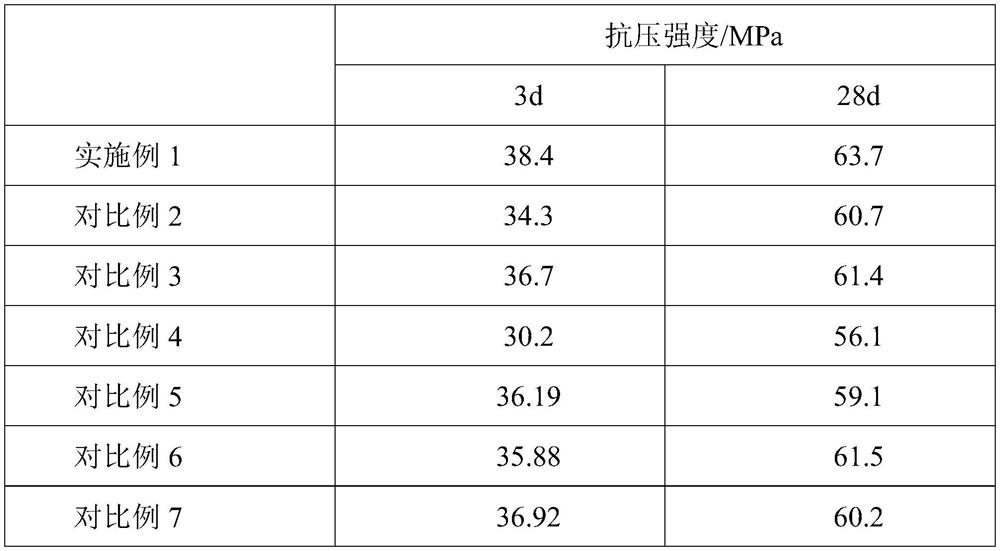

Examples

Embodiment 1

[0029] A method for calcining cement clinker with high-sulfur coal as fuel, adding discarded fluorite ore mining waste slag and lead-zinc slag as raw materials during raw meal preparation, and the specific production steps include:

[0030] Select fluorite ore mining waste slag as siliceous material for crushing, and select lead-zinc slag for crushing and standby;

[0031] In terms of mass percentage, 75% of limestone, 3% of siliceous material fluorite ore mining waste slag, 10% of aluminum material, and 1% of lead-zinc slag are mixed and ground to obtain raw meal for use; the CaO content of the fluorite ore mining waste slag exceeds 30% calcareous material as cement ingredient; the fluorite mine mining waste slag SiO 2 Content up to 90%, CaF 2content of 3%; the aluminum material is shale; the raw meal composition should meet the requirements of the design three rate values of calcined cement clinker, namely, KH=1.020±0.02, n=2.6±0.1, p=1.5 ±0.1; CaF in the raw meal 2 The...

Embodiment 2

[0034] A method for calcining cement clinker with high-sulfur coal as fuel, adding discarded fluorite ore mining waste slag and lead-zinc slag as raw materials during raw meal preparation, and the specific production steps include:

[0035] Select fluorite ore mining waste slag as siliceous material for crushing, and select lead-zinc slag for crushing and standby;

[0036] In terms of mass percentage, 85% of limestone, 7% of siliceous material fluorite ore mining waste slag, 15% of aluminum material, and 4% of lead-zinc slag are mixed and ground to obtain raw meal for use; the CaO content of the fluorite ore mining waste slag exceeds 30% calcareous material as cement ingredient; the fluorite mine mining waste slag SiO 2 Content up to 90%, CaF 2 content of 3%; the aluminum material is clay; the raw meal composition should meet the requirements of the design three-rate value of calcined cement clinker, that is, KH=1.020±0.02, n=2.6±0.1, p=1.5± 0.1; CaF in the raw meal 2 The c...

Embodiment 3

[0039] A method for calcining cement clinker with high-sulfur coal as fuel, adding discarded fluorite ore mining waste slag and lead-zinc slag as raw materials during raw meal preparation, and the specific production steps include:

[0040] Select fluorite ore mining waste slag as siliceous material for crushing, and select lead-zinc slag for crushing and standby;

[0041] In terms of mass percentage, 85% of limestone, 3% of siliceous material fluorite ore mining waste slag, 15% of aluminum material, and 1% of lead-zinc slag are mixed and ground to obtain raw meal for use; the CaO content of the fluorite ore mining waste slag exceeds 30% calcareous material as cement ingredient; the fluorite mine mining waste slag SiO 2 Content up to 90%, CaF 2 content of 3%; the aluminum material is one or more of shale and clay; the raw meal composition should meet the requirements of the design third rate value of calcined cement clinker, that is, KH=1.020±0.02, n=2.6±0.1, p=1.5±0.1; CaF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com