Melting pipe connector sealing equipment for plastic mold production

A plastic mold and interface technology is applied in the field of melting pipe interface sealing equipment for plastic mold production, and achieves the effect of good pipe sealing effect and improved cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

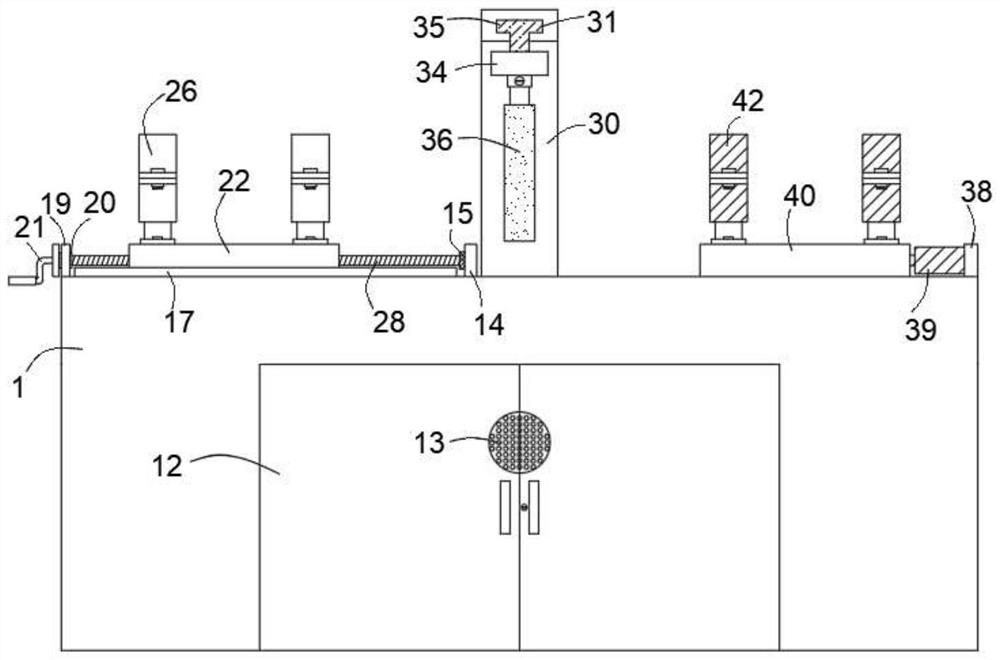

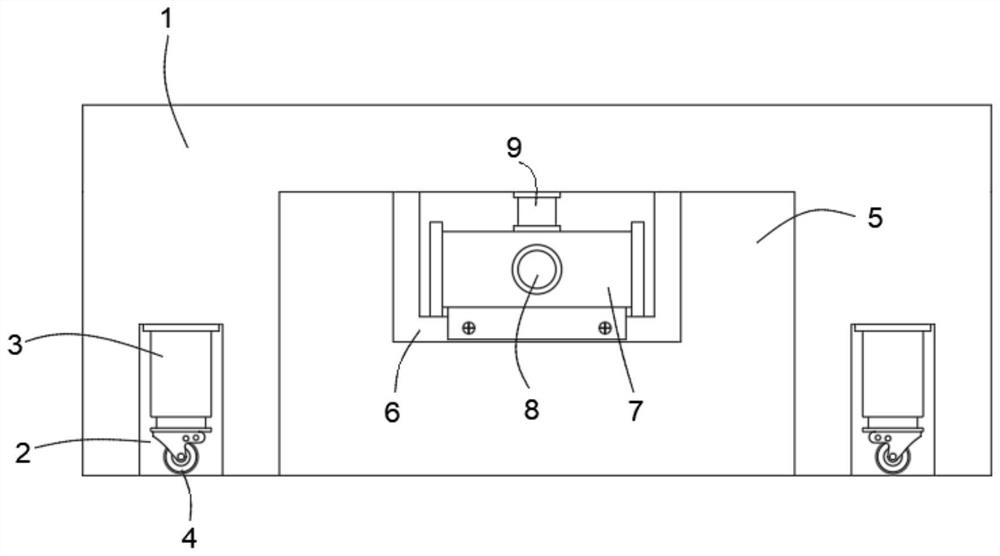

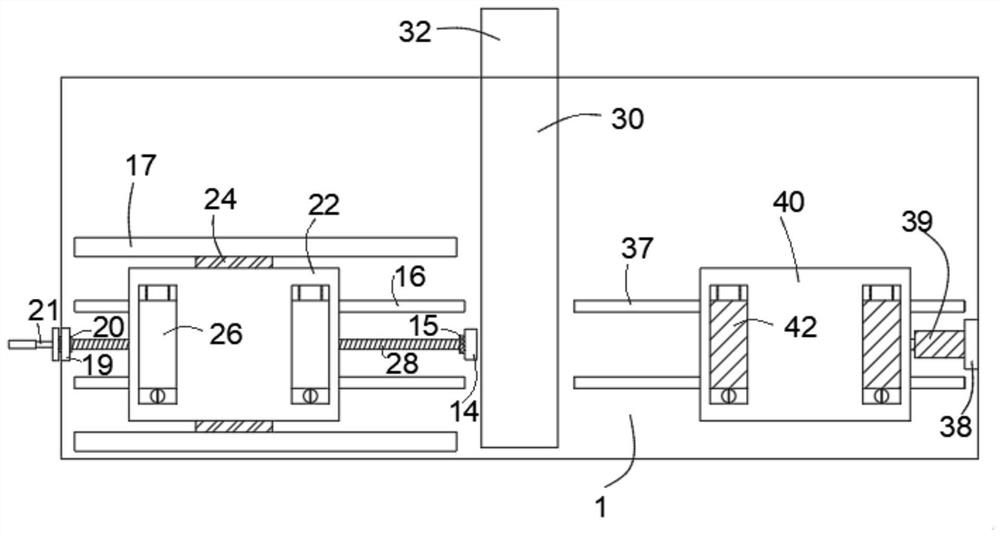

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. The embodiments described below with reference to the accompanying drawings are exemplary, only used to explain the present invention, and should not be construed as a limitation of the present invention.

[0038] The embodiments of the present invention will be described below based on the overall structure of the present invention.

[0039] A melting pipe interface sealing equipment for plastic mold production, such as Figure 1-11As shown, the air inlet duct 8 is installed on the front and rear sides of the air cooler 7, and the air outlet duct 9 is installed on the upper side of the air cooler 7, the top of the air outlet duct 9 penetrates the upper side of the workbench 1, and the upper side of the air outlet duct 9 is connected. There is a shunt pipe 10, and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com