Accelerator pedal arm supporting seat bottom face finish machining machine tool

A technology of accelerator pedal and support seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

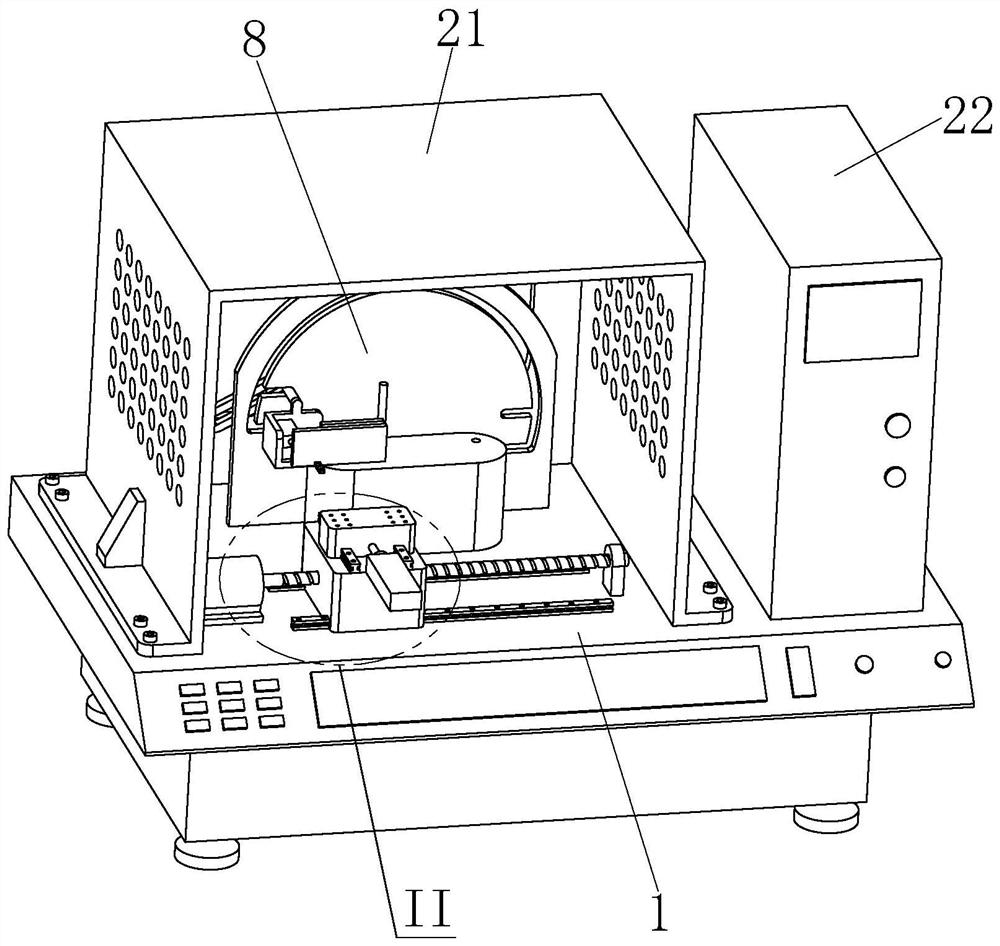

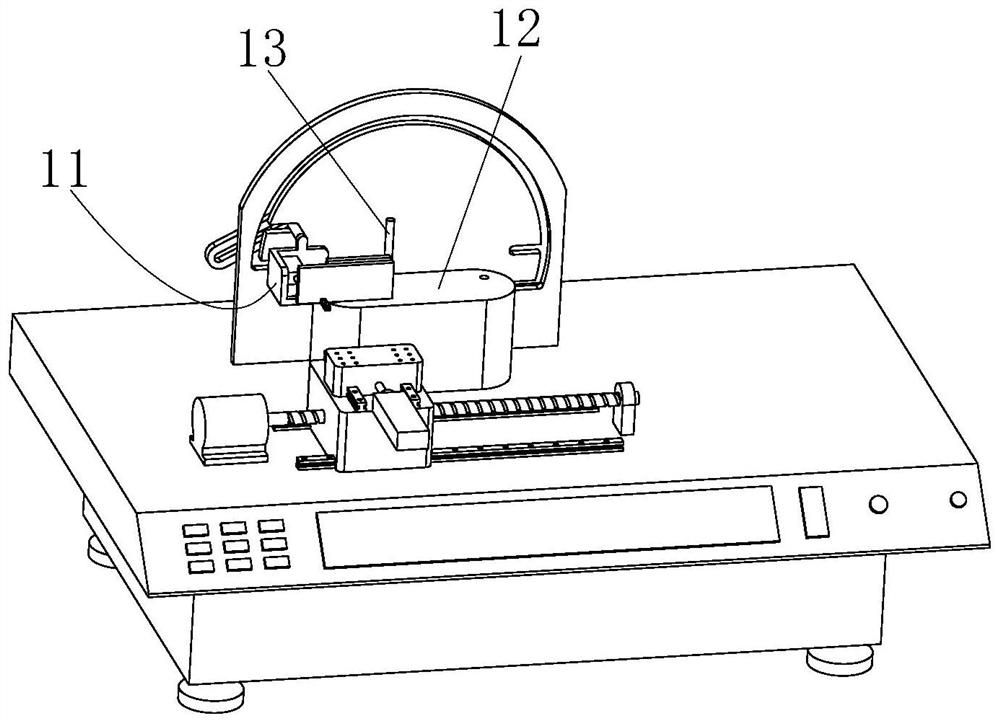

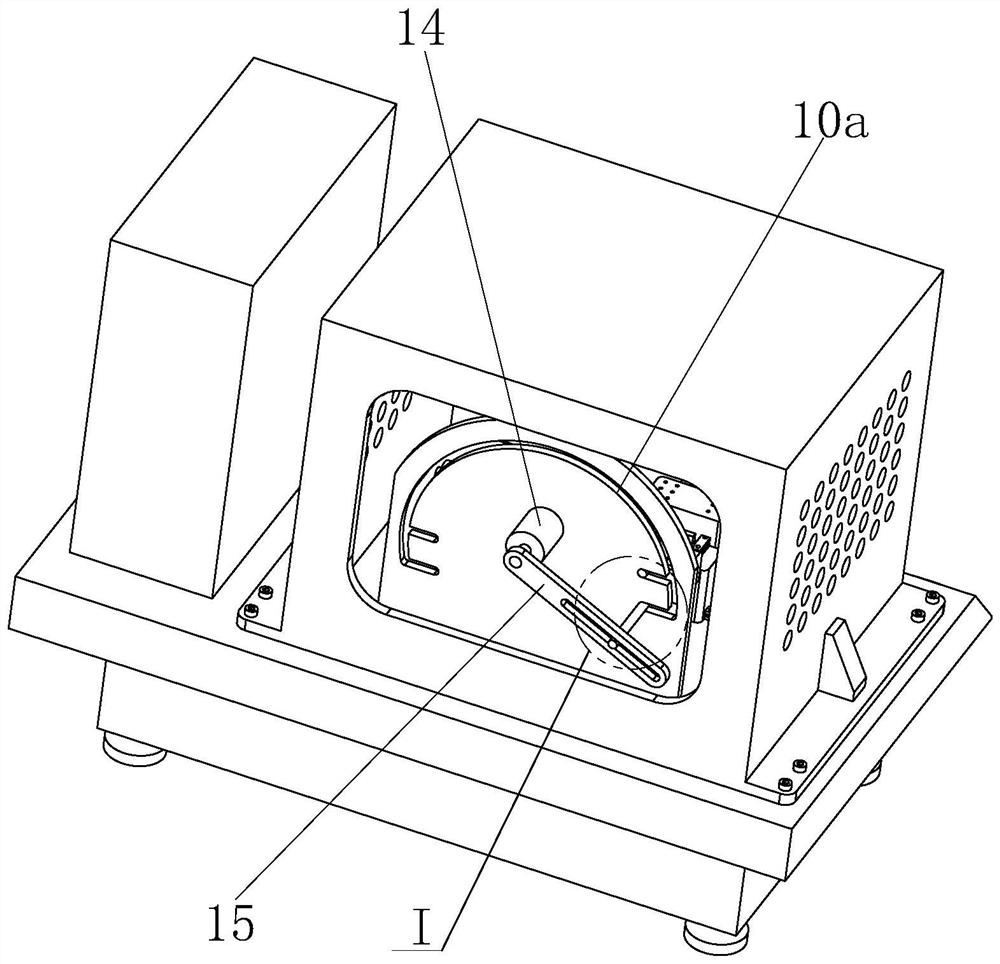

[0035] like Figure 1 to Figure 7 As shown in the figure, the bottom surface of the accelerator pedal arm support base is a finishing machine tool, and a host table 1 is provided. The upper and front part of the host table 1 is installed with a two-degree automatic moving mechanism, and the two-automatic moving mechanism is connected with the main mounting seat 2; The rear part is respectively provided with a positioning assembly, a clamping assembly and a clamp-changing moving assembly; the clamping-changing moving assembly includes a rail placement plate 8 installed on the main table 1, and the rail placement plate 8 is slidably fitted with I-type connecting rods 9 and II-type connecting rods respectively. The connecting rod 10; the clamping assembly includes a three-sided load frame 11 which is connected to the I-type connecting rod 9 and the II-type connecting rod 10 by welding.

[0036] like figure 1 As shown, an outer cover 21 and an electric control box 22 are respecti...

Embodiment 2

[0047] The present invention also further proposes a working method, specifically:

[0048] In the initial state, the I-type connecting rod 9 and the II-type connecting rod 10 are respectively located at the right limit positions of the two horizontal grooves 10b on the left side.

[0049] Before use, the external finishing equipment is manually installed on the main mounting seat 2 .

[0050] The specific use steps are as follows:

[0051] Step one, as Figure 8 The illustrated accelerator pedal arm support is placed on the pad 12 with the bottom facing forward, and the shaft hole on the workpiece is matched with the positioning pin 13, and the left end of the bottom of the workpiece is abutted with the fixed clamping plate 18.

[0052] Step 2. The air cylinder 16 pulls the movable clamping plate 19 back, and clamps the bottom left end of the workpiece. The clamped state is as follows: Figure 9 shown.

[0053] Step 3: Process the right half of the bottom surface of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com