Automatic efficient spring manufacturing production line and process

A production line and spring chamber technology, which is applied in the field of automatic and efficient production of springs and processes, can solve the problems of unreasonable design of the spring pulling connection, high technical requirements of people, low degree of automation, etc., and achieves compact structure, low cost, The effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

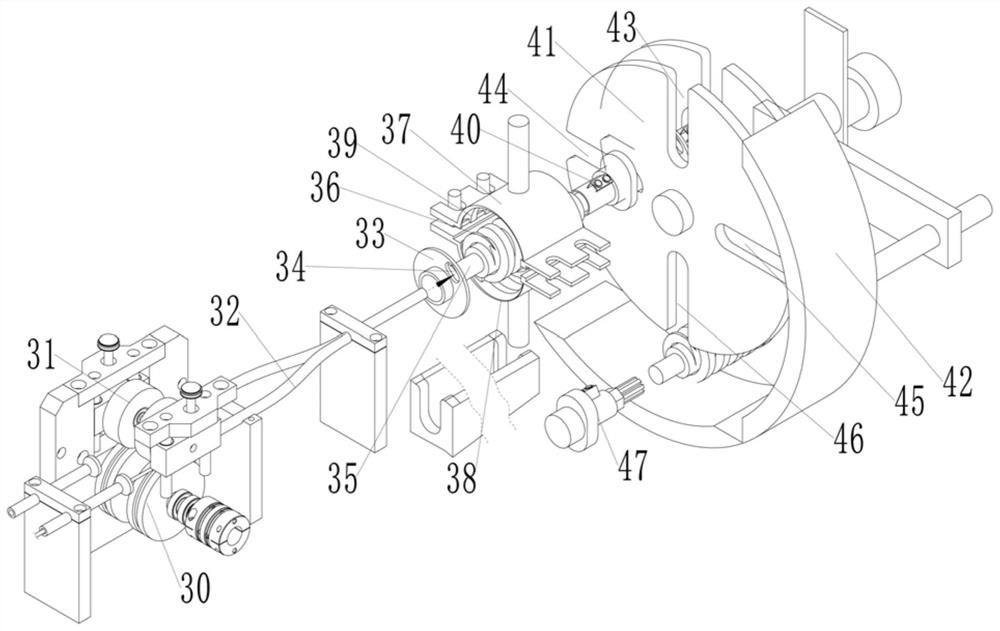

[0068] like Figure 1-5 As shown, in the spring product of this embodiment, the spring product 61 includes a helical shaped spring 62; the shaped spring 62 has two ends, and a first end cap 63 and a second end cap are respectively connected to the two ends of the shaped spring 62 end cap 64;

[0069] The first end cap 63 and / or the second end cap 64 has a hollow hole and a connecting flange; the hollow hole is welded to the end of the formed spring 62, and the connecting flange is used to connect the corresponding pulling member.

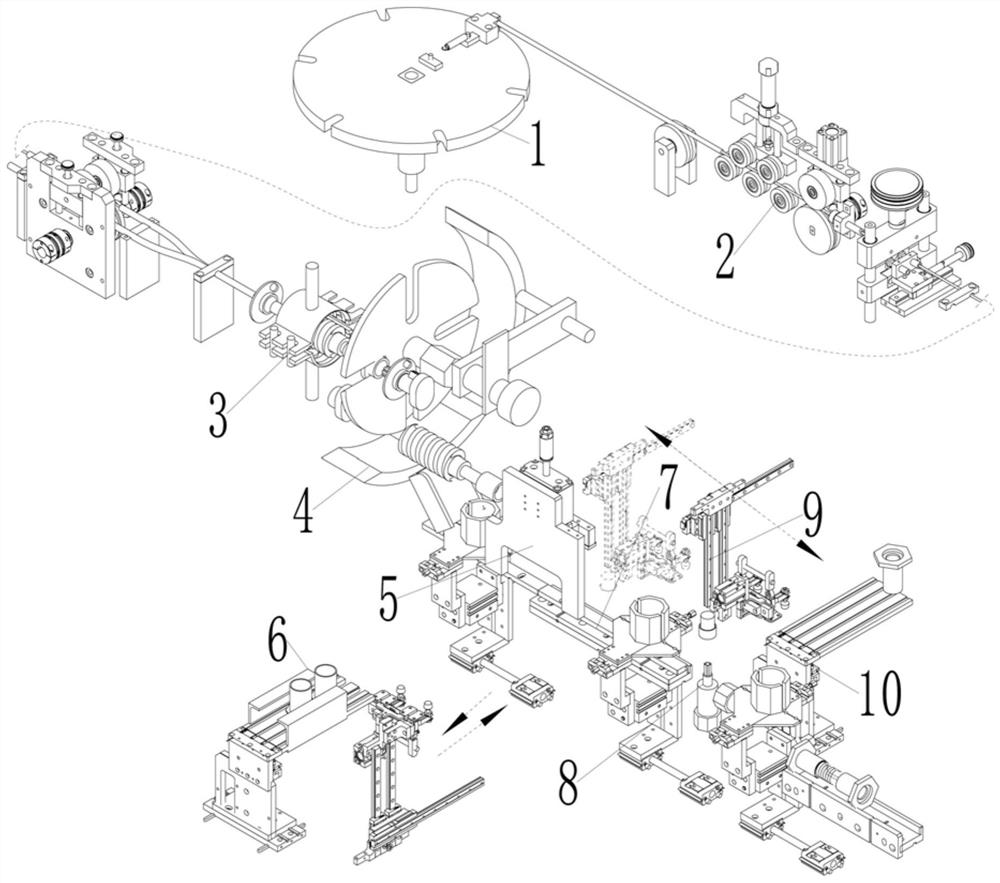

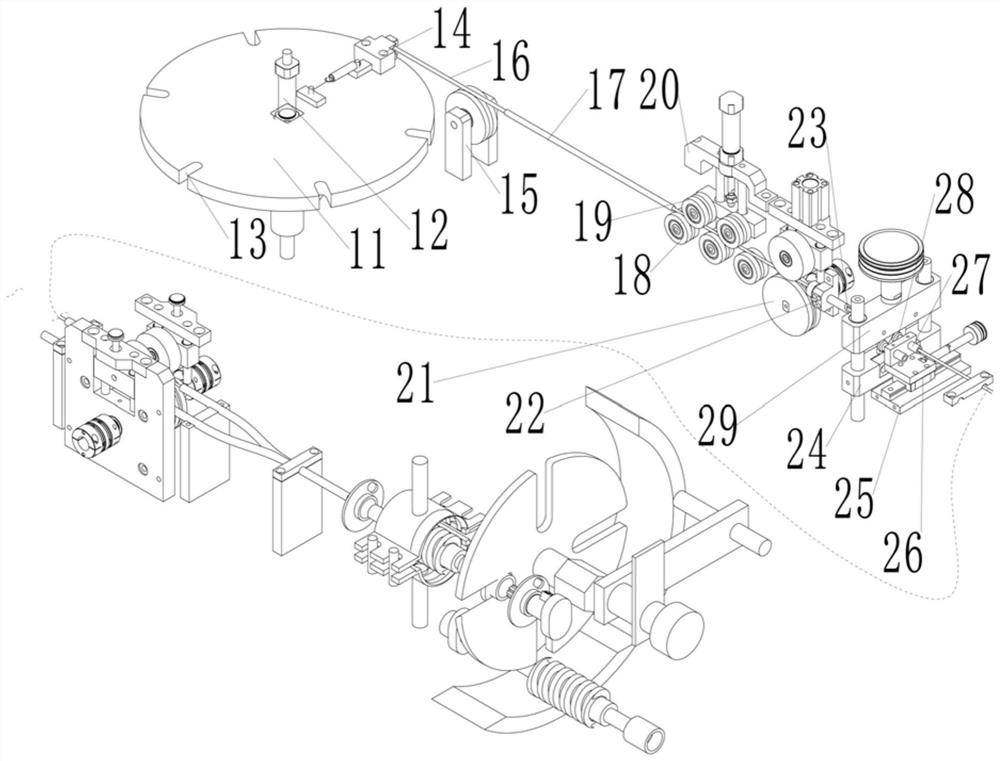

[0070] Automated processing equipment includes

[0071] The spring chamber reel seat 1, on the spring chamber reel seat 1, is coiled with a spring wire 16, the spring chamber reel seat 1 drives the spring wire 16 to rotate or the spring wire 16 rotates on the spring chamber reel seat 1, so that the Spring wire 16 linear output;

[0072] The straightening assembly 2 receives the spring wire 16 output by the spring chamber reel seat 1, and straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com