Seal welding device for quartz crystal resonator wafer

A quartz crystal and resonator technology, applied in the field of quartz crystal resonator wafer processing, can solve the problems of sealing and welding quality impact, metal debris scattering, metal debris splashing, etc., to achieve the effect of ensuring the quality of removal and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

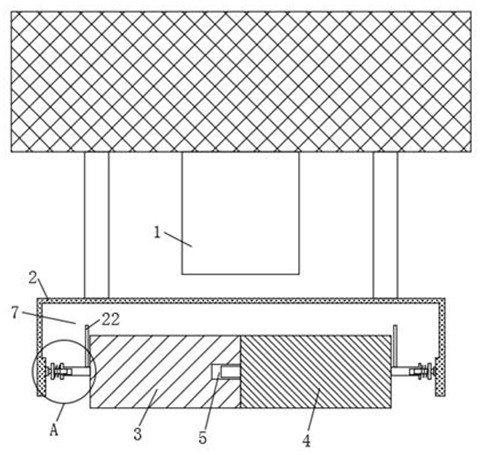

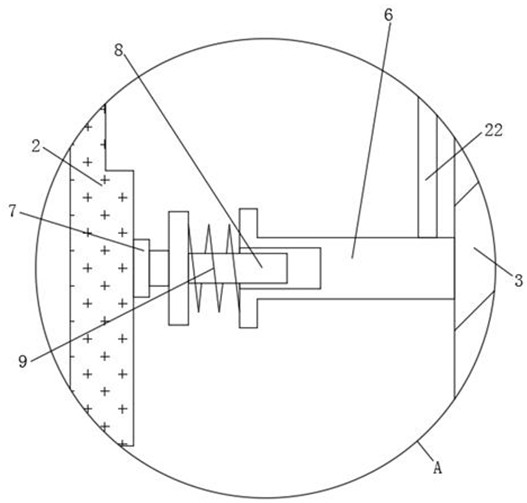

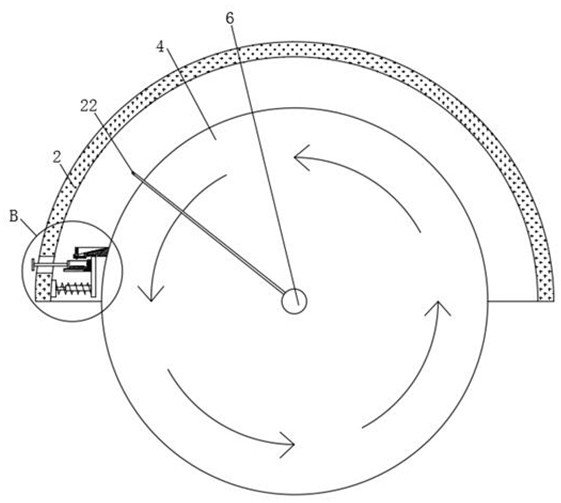

[0038] refer to Figure 1-Figure 10, a sealing and welding device for a quartz crystal resonator chip, comprising a sealing and welding device body 1, a fixed shell 2 is fixedly installed at the lower end of the sealing and welding device body 1, and a sticking roller 3 is provided on the left side of the fixed shell 2. The sticking roller There is a sticking roller 24 on the right side of the first 3, and the middle part of the right end of the sticking roll 1 3 is provided with a slot 5 corresponding to the sticking roll 2 4. The two rollers 4 are attached, and the ends of the sticking rollers 1 3 and the sticking rollers 2 4 are fixedly installed with the rotating shaft 6, and the one end of the rotating shaft 6 that is far away from each other is inserted with an insert rod 8, and the end of the sticking rod 8 that is far away from each other is inserted. Bearings 7 are fixedly installed, and the ends of the bearings 7 away from each other are fixedly installed on the fixe...

Embodiment 2

[0040] refer to Figure 1-Figure 10 , In this embodiment, it is basically the same as the first embodiment, and it is more optimized that a clearing plate 10 is provided on the front side of the sticking roller one 3 and sticking roller two 4, and the clearing plate 10 is connected with sticking roll one 3 and sticking roll two 4. The lower end of the clearing plate 10 is fixedly installed with a connecting plate 11, the front end of the connecting plate 11 is symmetrically fixed with a telescopic rod 12, the front end of the telescopic rod 12 is fixedly installed on the fixed shell 2, and the telescopic rod 12 is fixed on the A spring two 13 is sleeved, and the front and rear ends of the spring two 13 are fixedly installed on the fixed shell 2 and the connecting plate 11 respectively. There is a baffle 15, the lower end of the clearing plate 10 is fixedly installed with a limit clip 16 corresponding to the baffle 15, and the baffle 15 runs through the limit clip 16, and the b...

Embodiment 3

[0042] refer to Figure 1-Figure 10 , in this embodiment, it is basically the same as the first embodiment, and it is more optimized that a plurality of air outlet holes 23 are opened inside the cleaning plate 10, and one end of the connection pipe 24 is fixedly installed at the lower end of the air outlet hole 23, and the other end of the connection pipe 24 is installed. An air cylinder 25 is communicated with, the air cylinder 25 is fixedly installed on the support plate 19, the rear end of the air cylinder 25 is inserted with a piston 26, and the rear end of the piston 26 is fixedly installed on the pressing plate 20; during use, and the pressing plate 20 moves forward. It will drive the piston 26 to move forward, and the piston 26 squeezes the gas in the gas cylinder 25 out through the connecting pipe 24 and the gas outlet 23. The debris is accumulated inside the cleaning plate 10 , so that the debris can be easily discharged from the discharge opening 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com