Catalyst for catalyzing alkane dehydrogenation to synthesize olefin as well as preparation method and application of catalyst

A technology for catalyzing alkanes and catalysts, which is applied in the field of catalysts for catalyzing alkane dehydrogenation to synthesize alkenes and their preparation, and can solve the problems of environmental pollution, development limitation of chromium oxide-based catalysts, and low ethylene selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

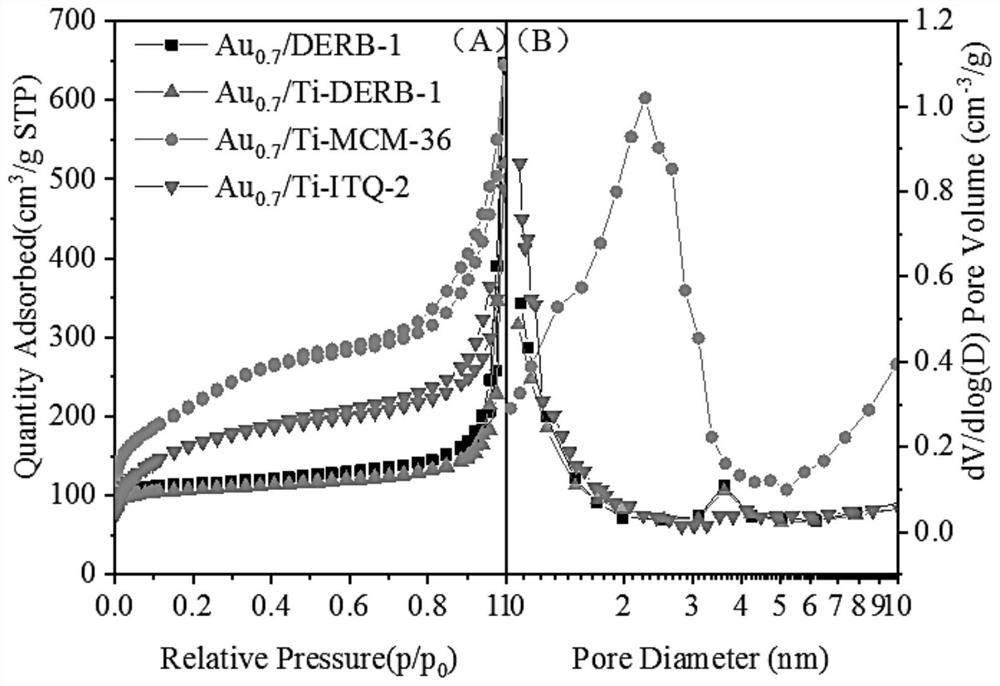

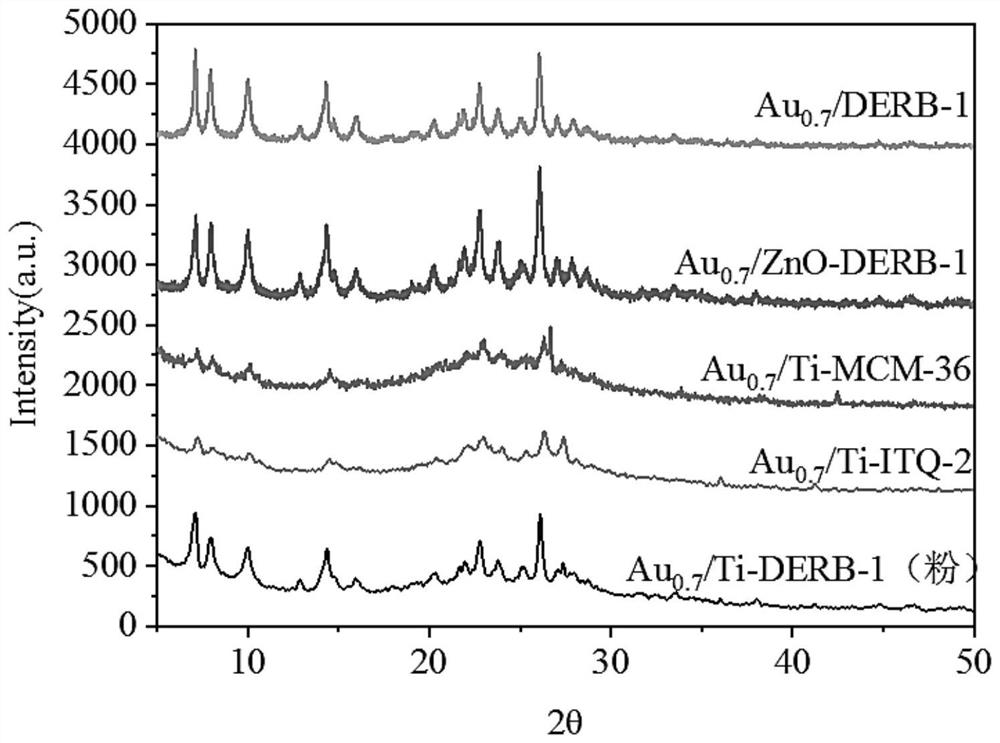

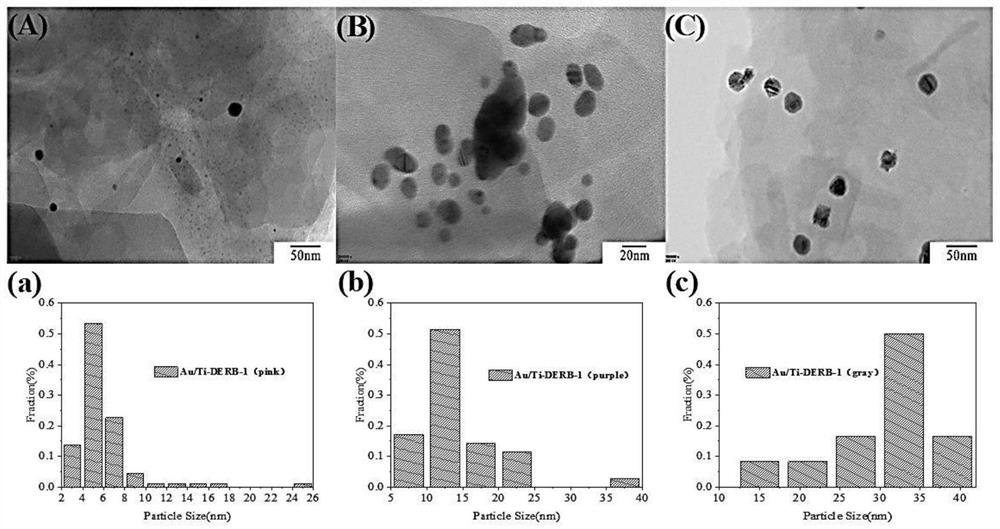

[0063] Preparation of Au / Ti-ITQ-2 catalysts. AuCl 3 ·HCl·4H 2 O was dissolved in deionized water, and after stirring evenly, 0.1 mol / L AuCl was obtained 3 solution. Take the above AuCl 3 0.4ml of the solution was dissolved in 25ml of deionized water, stirred for 20min, and adjusted to pH 9.23 with 0.1mol / L NaOH solution. The duration of this process was 5.5h. After pH adjustment, 0.56g of Ti-ITQ-2 carrier was added and stirred. After homogenization, the pH was adjusted to 10 with 0.3 mol / L NaOH solution. The duration of this process was 2.5 h. The obtained mixture was centrifuged. The separated solid was vacuum-dried at 70 °C for 10 h, and then calcined at 250 °C for 3 h. , you can get C 2 H 6 Dehydrogenation to C 2 H 4 The catalyst, the mass fraction of gold in the catalyst is 0.7%, denoted as Au 0.7 / Ti-ITQ-2.

Embodiment 2

[0065] Preparation of Au / DERB-1 catalyst. AuCl 3 ·HCL·4H 2 O was dissolved in deionized water, and after stirring evenly, 0.1 mol / L AuCl was obtained 3 solution. Take the above AuCl 3Dissolve 0.5ml of the solution in 25ml of deionized water, stir for 20min, and adjust the pH to 9.12 with 0.1mol / L NaOH solution. The duration of this process is 5h. Then use 0.3mol / L NaOH solution to adjust the pH to 10, the duration of this process is 2.5h, the obtained mixture is centrifuged, the separated solid is vacuum-dried at 70°C for 10h, and then calcined at 250°C for 3h. get C 2 H 6 Dehydrogenation to C 2 H 4 The catalyst, the mass fraction of gold in the catalyst is 0.7%, denoted as Au 0.7 / DERB-1.

Embodiment 3

[0067] Preparation of Au / Ti-MCM-36 catalyst. 0.1g AuCl 3 ·HCL·4H 2 O was dissolved in deionized water, and after stirring evenly, 0.05mol / L AuCl was obtained 3 solution. Take the above AuCl 3 0.4ml of the solution was dissolved in 25ml of deionized water, stirred for 20min, and adjusted to pH 6.23 with 0.1mol / L NaOH solution. The duration of this process was 5h. After pH adjustment, 0.56g of Ti-MCM-36 carrier was added, and after stirring evenly , and then adjusted the pH to 9 with 0.1 mol / L NaOH solution. The duration of this process was 2.5 h. The obtained mixture was centrifuged. The solid obtained by separation was vacuum dried at 70 °C for 10 h, and then calcined at 250 °C for 3 h, that is, available C 2 H 6 Dehydrogenation to C 2 H 4 The catalyst, the mass fraction of gold in the catalyst is 0.7%, denoted as Au 0.7 / Ti-MCM-36.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com