System for monitoring pressure in cavity in medicine granulation process

A monitoring system and internal pressure technology, applied in the direction of measuring the pressure difference between multiple valves, measuring fluid pressure, making medicines into special physical or taking forms, etc., can solve the problem of affecting the drying effect, dead zone, Problems such as uneven air distribution, to achieve the effect of speeding up efficiency and quality of finished products, avoiding blockage, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

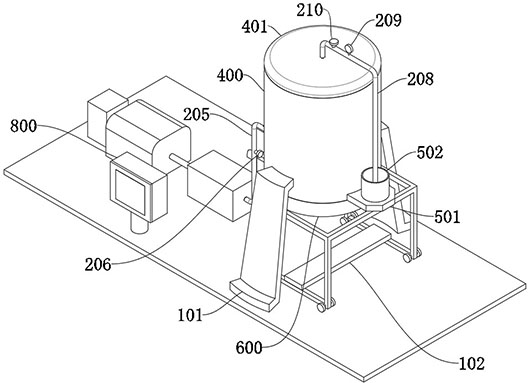

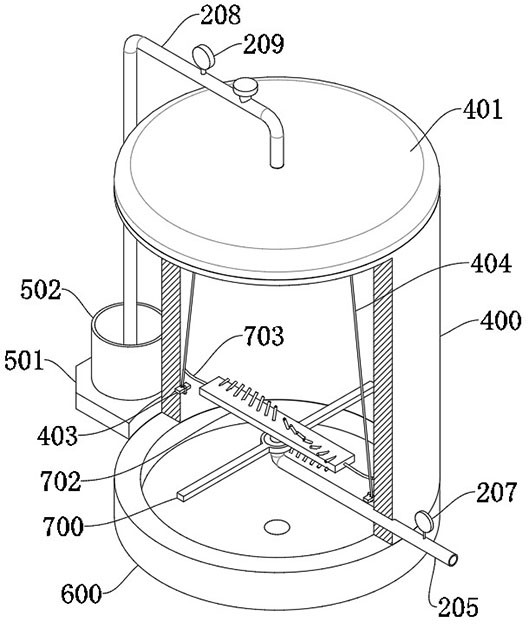

[0048] like Figure 1-Figure 8 As shown, the present invention provides an intra-cavity pressure monitoring system in the process of drug granulation, including: a drying tank 400, the drying tank 400 is used to provide an environment for drying and granulating liquid drugs;

[0049] Air supply mechanism, the air supply mechanism is used to deliver high temperature and high pressure gas to the inside of the drying tank 400;

[0050] The intake air pressure monitoring sensor 207, the intake air pressure monitoring sensor 207 is used to monitor the intake air pressure when the air supply mechanism sends gas to the drying tank 400;

[0051] The outlet air pressure monitoring sensor 209; the outlet air pressure monitoring sensor 209 is used to monitor the pressure when the drying tank 400 is exhausted;

[0052] The controller 802 calculates the current internal air velocity of the drying tank 400 in real time according to the pressure values transmitted by the inlet air pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com