Intelligent normal-pressure far infrared drying method for frozen grains

A grain drying and far-infrared technology, applied in the direction of drying and preserving seeds, to achieve the effects of reducing energy consumption, increasing work efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

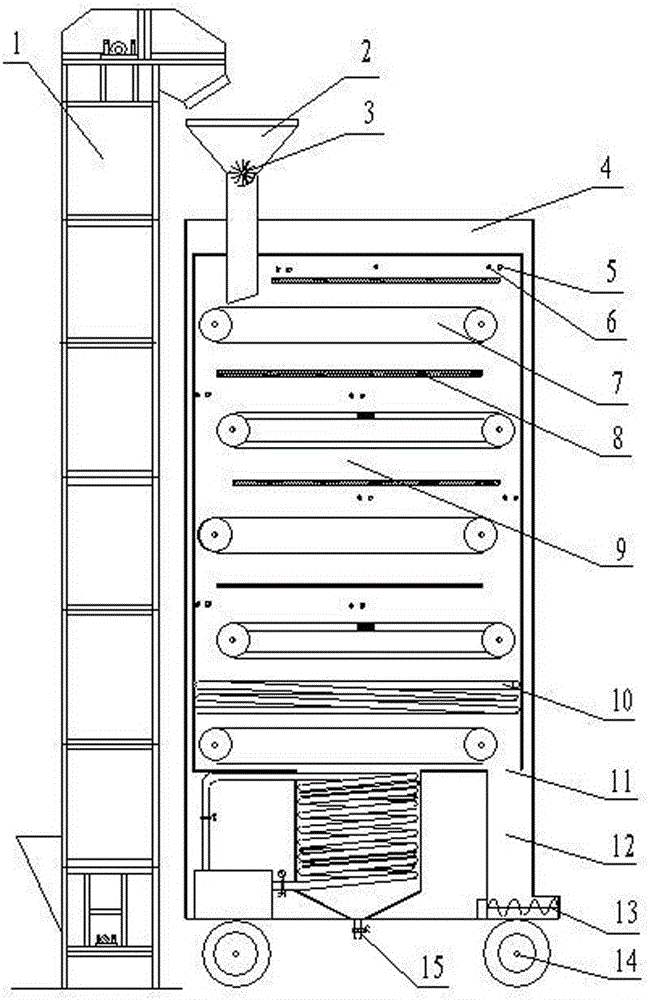

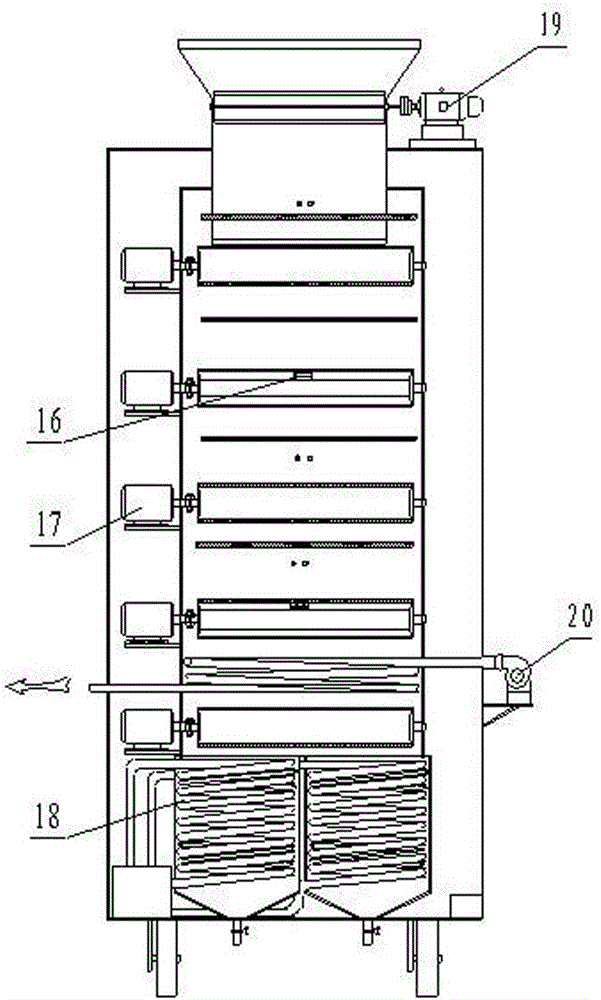

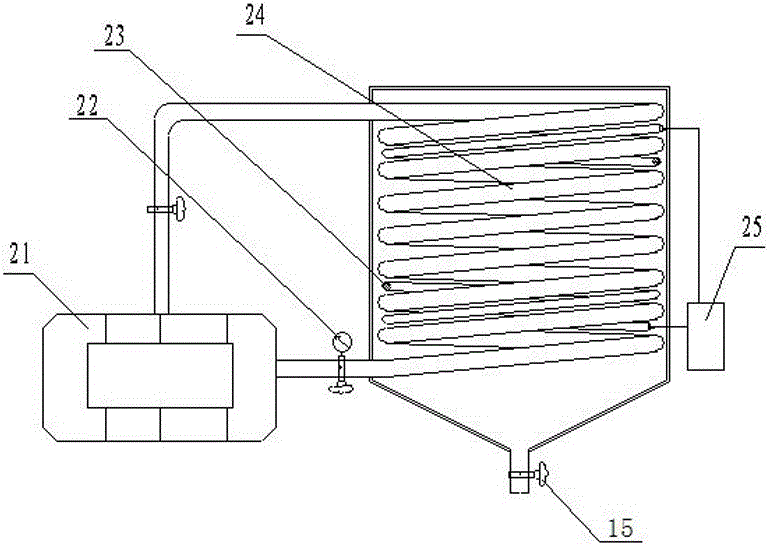

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

[0030] combine Figure 4 , Figure 5 , Figure 6 As shown, this intelligent normal-pressure far-infrared freezing grain drying method:

[0031] The frozen grain is raised from the elevator to the top of the dryer, and is precisely controlled by the impeller flow device at the bottom of the feed hopper 2 to enter the material conveyor belt and spread evenly;

[0032] With the operation of the material conveyor belt 7, through the multi-level far-infrared radiation heating method, the temperature sensor 5, the humidity sensor 6 and the weight sensor 16 in the dryer are used for real-time monitoring, and the radiation power of the far-infrared heating plate and the material conveyor belt 7 are adjusted in real time. Speed, optimized to realize the intelligent control of the whole process of grain drying; in the process of freeze-drying grain at atmospheric pressure, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com