Method for cleaning spiral-wound membrane for water treatment

A roll membrane, water treatment technology, applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, membrane technology, etc., can solve the problem that the performance of membrane elements cannot be effectively restored, the service life of membrane elements is affected, and the production load is affected. problems, to achieve the effect of shortening the cleaning time, reducing the consumption of cleaning chemicals, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

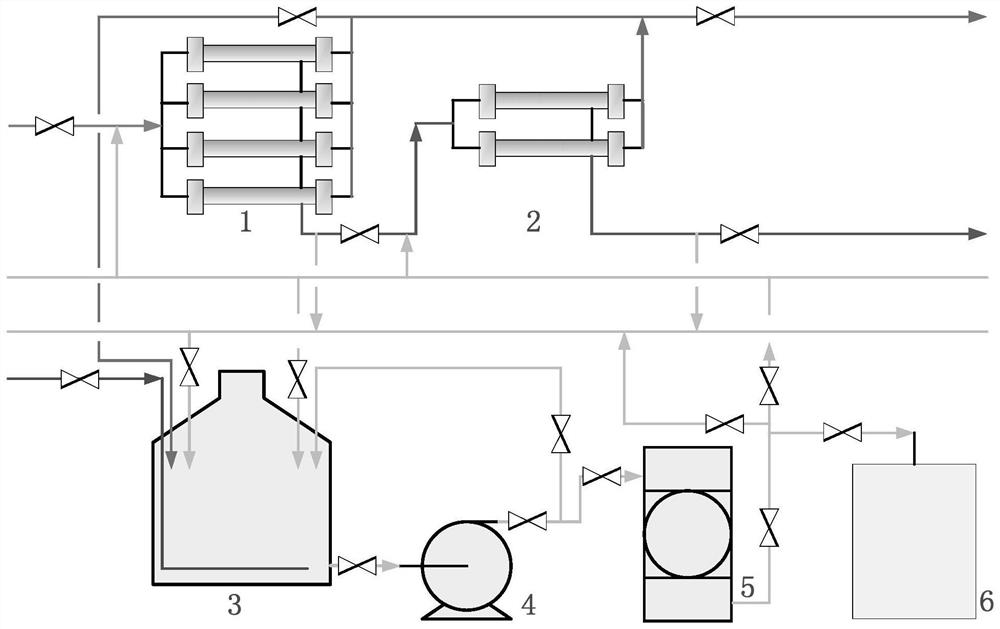

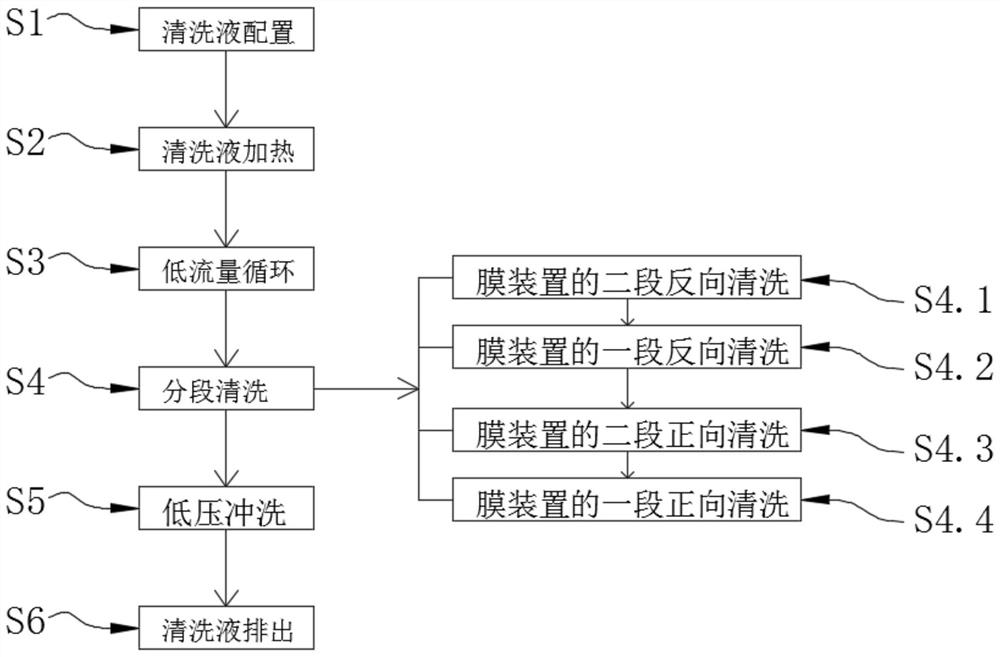

[0038] see Figure 1-Figure 2 , the present invention provides a method for cleaning a roll membrane for water treatment, comprising the following steps:

[0039] S1, cleaning liquid configuration, use 1 / 2 of the total produced water of the membrane device to distribute water, and add acid cleaning liquid to the cleaning water tank 3;

[0040] S2. The cleaning liquid is heated, and the cleaning water pump 4 is switched to the cleaning water tank 3 for self-circulation. After the liquid level of the cleaning water tank 3 reaches 1 / 2, the cleaning water pump 4 is started, and the mixed medicine is circulated. The monitoring system monitors that the pH value of the acid cleaning liquid is less than 2, and the cleaning water tank is 3. After the liquid level reaches 100%, the heating system of the cleaning water tank 3 is put into operation according to the actual needs, and the control temperature is lower than 40 ℃, and the heating methods include but are not limited to steam he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com