Aerosol generator and system

An aerosol generator and aerosol generation technology, which are used in inhalers, atomizers for treatment, etc., can solve the problems of difficult atomization and utilization of substrates, combustion of substrates, and long preheating time, so as to shorten the The effect of increasing atomization time, release amount and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

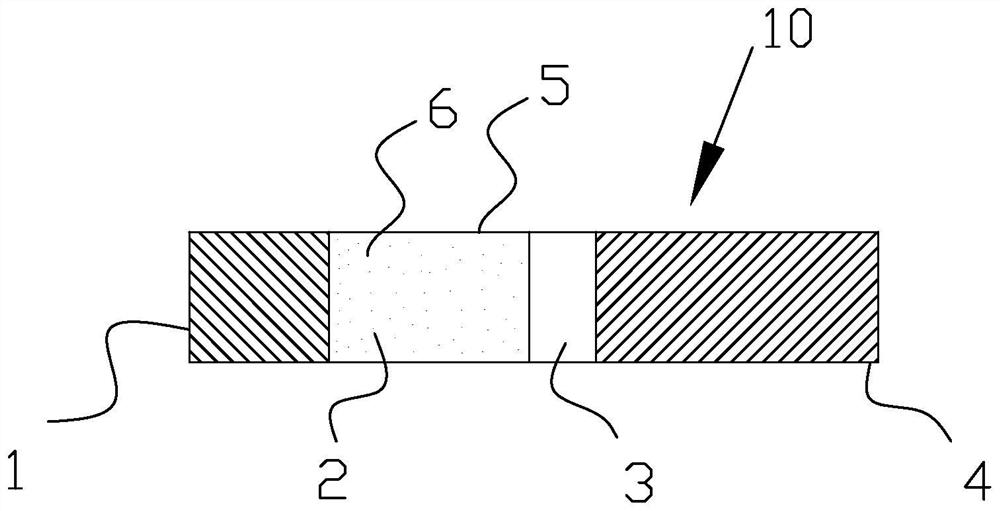

[0067] like figure 1 , according to an aerosol generator according to an embodiment of the present invention, the susceptor 1 is arranged in the case of a block structure, and is arranged on one side of the base material 2 . Along the aerosol diffusion direction, a susceptor 1 , a substrate 2 , a support member 3 and a suction nozzle member 4 are respectively provided.

[0068] The susceptor 1 is used to receive heat, microwave or electromagnetic field to generate heat, and is in thermal contact with the base material 2 , and supports the base material 2 .

[0069] The substrate 2 is used to form an aerosol under heating.

[0070] The support member 3, which is configured as a hollow flow channel structure or a porous flow channel structure, is arranged between the base material and the suction nozzle, and is used for supporting and insulating the base material 2 and guiding the aerosol.

[0071] The suction nozzle 4 is used for filtering and cooling the aerosol formed by th...

Embodiment 2

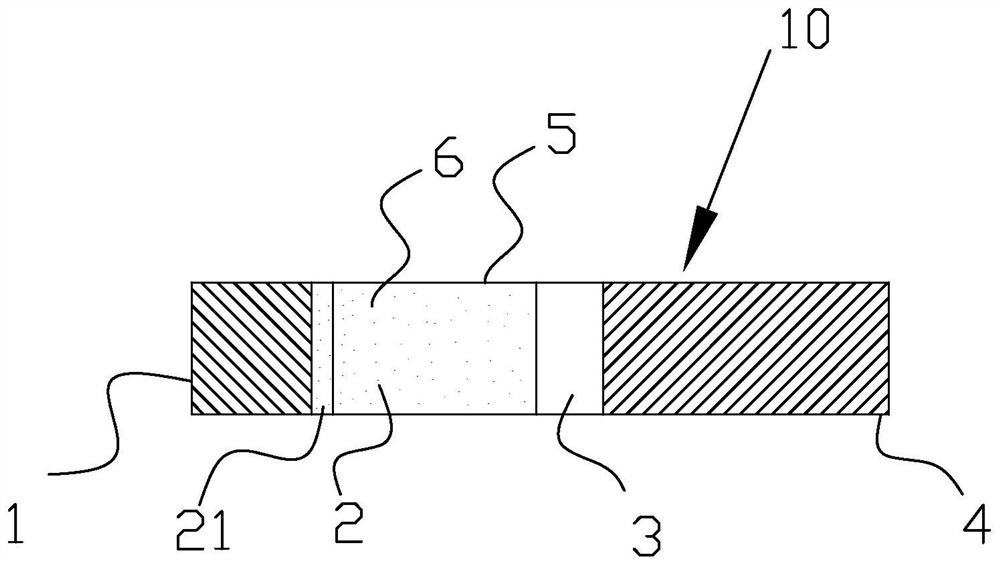

[0080] The difference from the first embodiment is that, as image 3 , the susceptor 1 is arranged in a hollow structure, and is arranged on one side of the base material 2 . The interior of the susceptor 1 is provided with an aerosol generating coating 21, so as to shorten the preheating time required for generating aerosol and generate aerosol quickly.

Embodiment 3

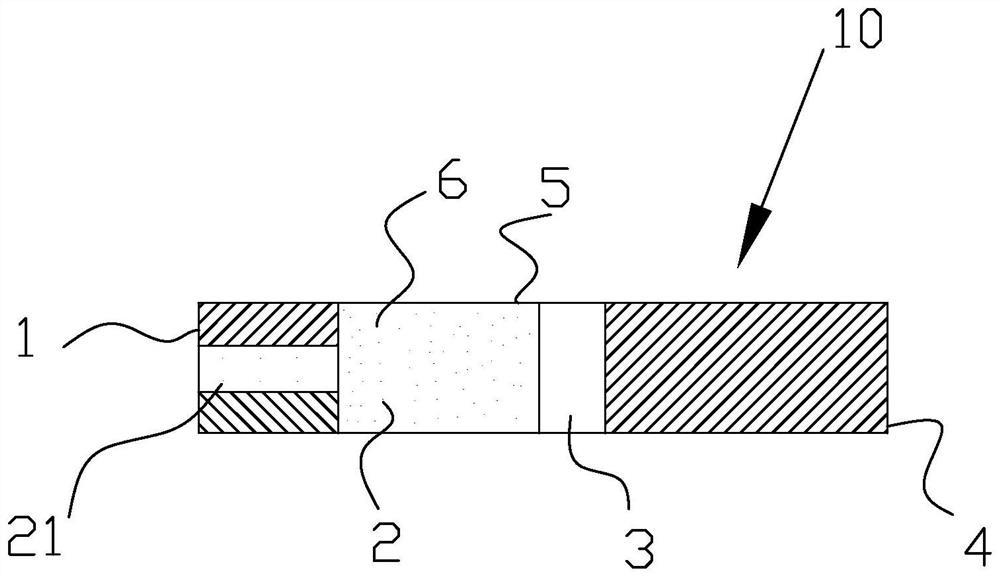

[0082] The difference from the first embodiment is that, as Figure 4 , the susceptor 1 is arranged in a porous structure, and is arranged on one side of the substrate 2 . The interior of the susceptor 1 is provided with an aerosol generating coating 21, so as to shorten the preheating time required for generating aerosol and generate aerosol quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com