Natural alginate fiber cat litter and preparation method thereof

A technology of seaweed fiber and cat litter, applied in animal houses, applications, animal husbandry, etc., can solve the problems of bean dregs fiber raw material shortage and unstable quality, reduce solid waste treatment costs, solve supply instability, and improve Effects on Usability and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] This embodiment provides a natural seaweed fiber cat litter, including 30 parts by weight of seaweed fiber, 30 parts of corn flour, 30 parts of corn starch, 4 parts of guar gum, 3 parts of water-absorbent resin and 3 parts of essence.

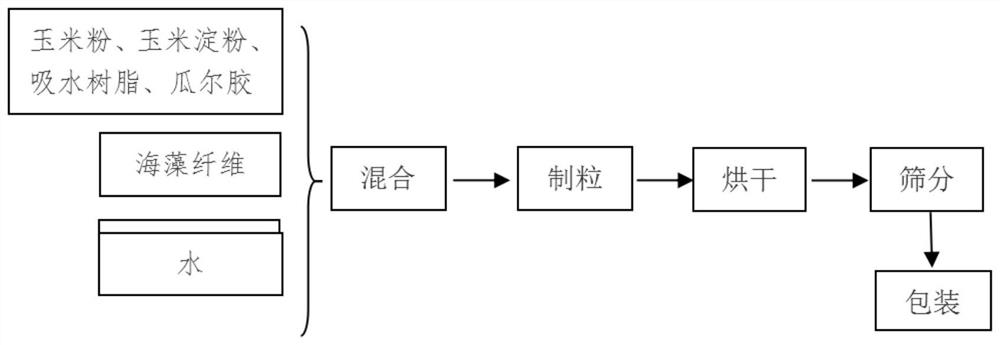

[0018] The preparation process of above-mentioned natural seaweed fiber cat litter is as follows figure 1 shown, including the following steps:

[0019] 1) Dissolve the essence in water evenly;

[0020] 2) adding the seaweed fiber to the mixer, adding the aqueous solution in step 1) to the mixer in the form of spraying, and mixing and stirring for 10 minutes until uniform;

[0021] 3) After the corn flour, corn starch, guar gum, and water-absorbent resin are mixed uniformly, they are added to the mixer, and mixed for 15 minutes until uniform;

[0022] 4) Passing the uniformly mixed raw materials through a cat litter granulator to produce cat litter particles of the required shape and specification;

[0023] 5) The cat litter after gra...

Embodiment 2

[0026] This embodiment provides a natural seaweed fiber cat litter, including 50 parts by weight of seaweed fiber, 22 parts of corn flour, 12 parts of corn starch, 8 parts of guar gum, 6 parts of water absorbent resin and 2 parts of essence.

[0027] The preparation process of above-mentioned natural seaweed fiber cat litter is as follows figure 1 shown, including the following steps:

[0028] 1) Dissolve the essence in water evenly;

[0029] 2) adding the seaweed fiber to the mixer, adding the aqueous solution in step 1) to the mixer in the form of spraying, and mixing and stirring for 10 minutes until uniform;

[0030] 3) After the corn flour, corn starch, guar gum, and water-absorbent resin are mixed uniformly, they are added to the mixer, and mixed for 15 minutes until uniform;

[0031] 4) Passing the uniformly mixed raw materials through a cat litter granulator to produce cat litter particles of the required shape and specification;

[0032] 5) The cat litter after gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com