Gas stove and method for controlling gas stove glass disc temperature

A technology for glass pans and gas furnaces, applied in the field of glass pan temperature control and glass pan temperature control devices, which can solve the problems of shortening the service life of glass pans (6), rising indoor temperature, and increasing carbon monoxide concentration, so as to improve usability and safety, reduce indoor temperature rise, and prevent explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

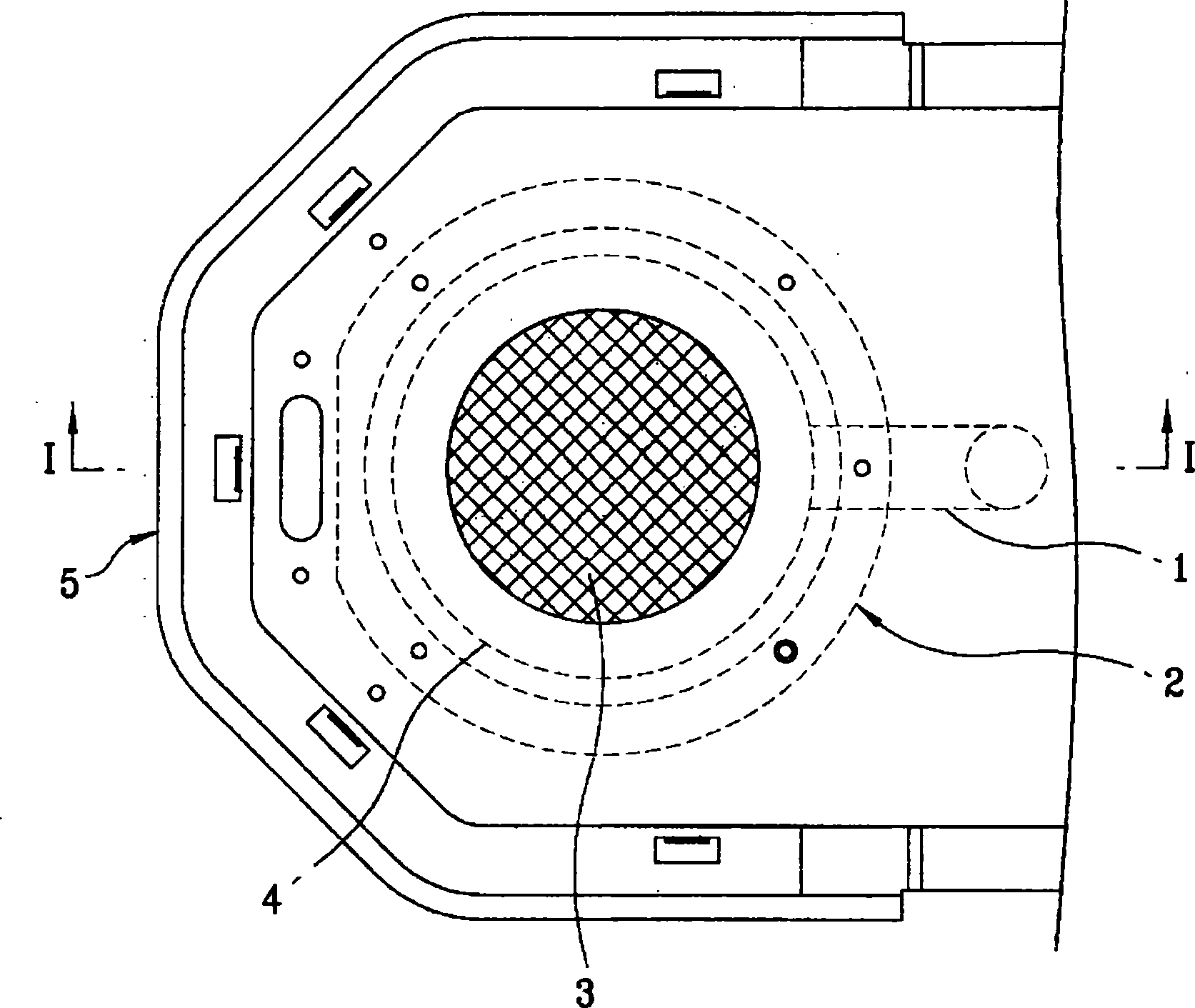

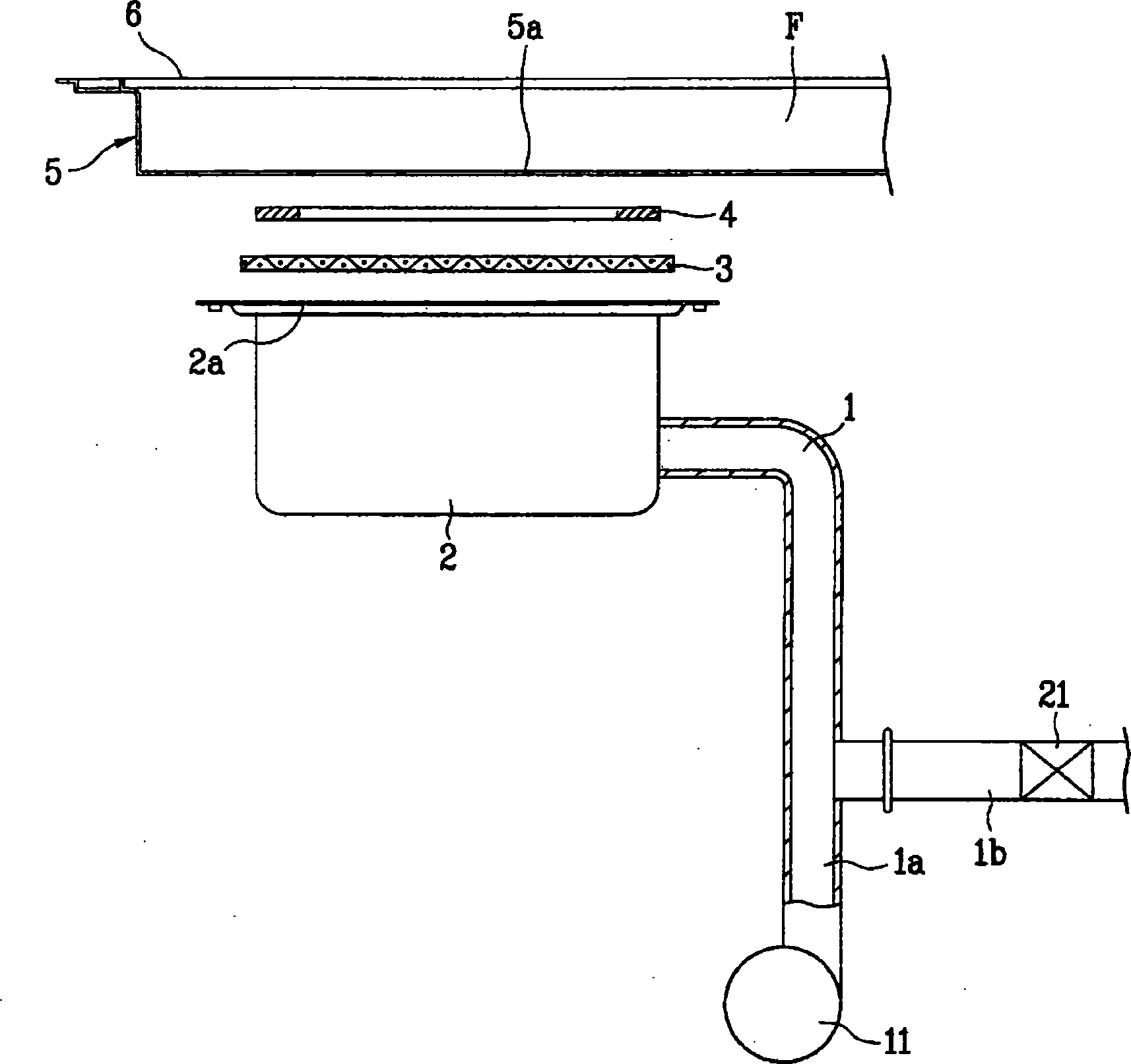

[0031] The gas furnace of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] In order to avoid duplication of description, the same reference numerals are used for the same components as in the prior art.

[0033] Such as Figure 4 As shown, in order to perceive the temperature of the glass dish (6), the gas furnace of the present invention is provided with a temperature sensor (100) on the lower surface of the glass dish (6), and is also provided with a temperature sensor connected to the temperature sensor and sensed according to the temperature sensor (100). The microcomputer (200) that controls the speed of the blower fan (11) according to the temperature of the glass plate (6).

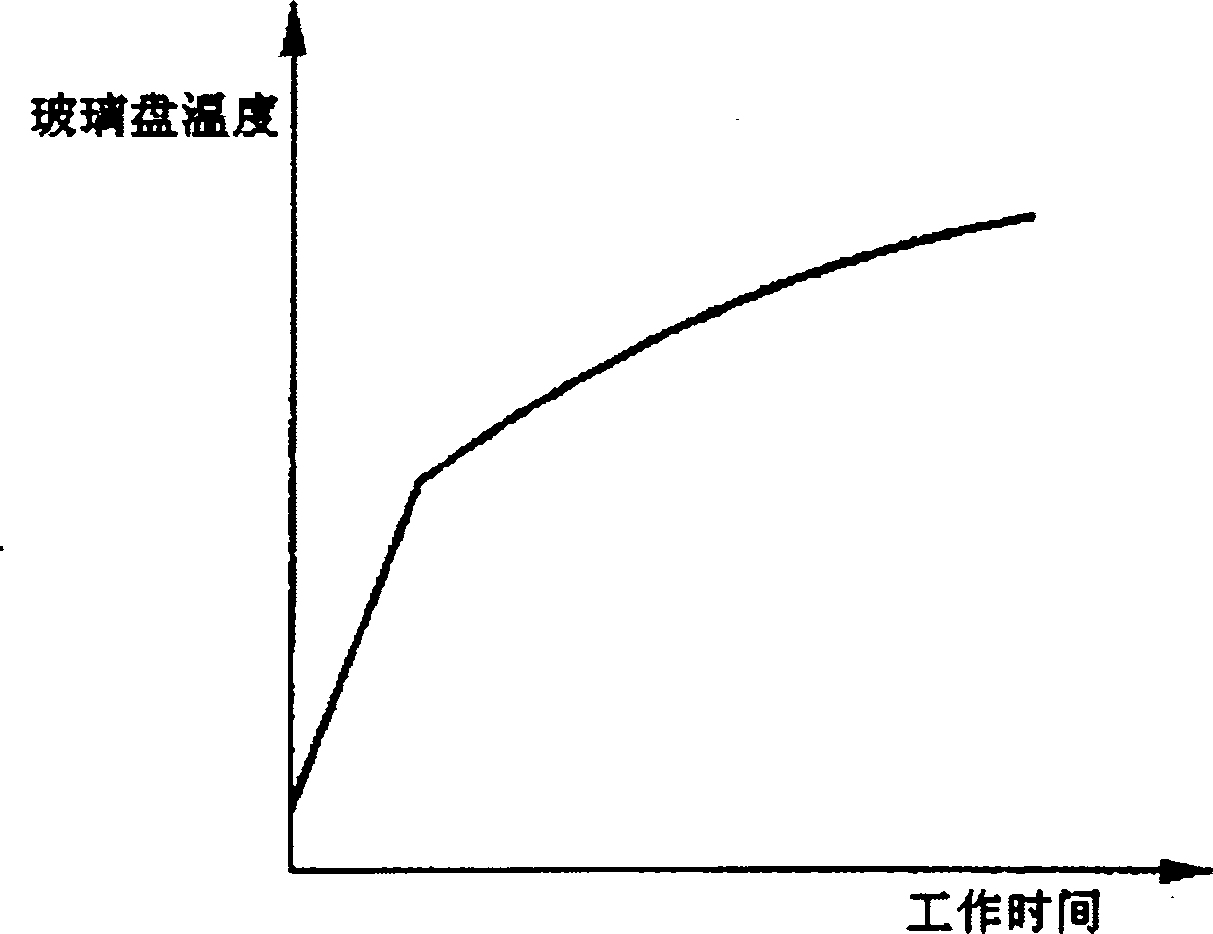

[0034] The temperature sensor (100) periodically measures the temperature of the glass plate (6), and when the temperature of the glass plate (6) rises above the reference value, the microcomputer (200) adjusts the speed of the blower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com