Blowing-in method of blast furnace

A blast furnace and charge technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as difficult to confirm detection, low carbon saturation, etc., achieve stable heat storage, increase carbon saturation, and avoid furnace conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The present embodiment provides a method for opening a blast furnace, and the method for opening a furnace includes sequentially performing furnace charge smelting, molten iron charge smelting, and stable smelting;

[0074] The blast furnace used in the described furnace is a blast furnace filled with sleepers in the hearth;

[0075] In the smelting of the open-furnace charge, the whole-furnace coke ratio of the open-furnace charge is 3.3 t / t, the amount of the blast furnace entering the furnace is 70% of the maximum air volume of the blast furnace, and the binary basicity of the obtained slag is 0.84;

[0076] The molten iron charge is smelted into a first smelting stage, a second smelting stage and a third smelting stage, with a total of 16 smelting cycles;

[0077] Wherein, the first smelting stage consists of 4 smelting cycles (in the first smelting cycle, the charge to coke ratio is 3.3t / t, and the binary basicity of the slag is controlled to be 0.84); with the inc...

Embodiment 2

[0084] The present embodiment provides a method for opening a blast furnace, and the method for opening a furnace includes sequentially performing furnace charge smelting, molten iron charge smelting, and stable smelting;

[0085] The blast furnace used in the described furnace is a blast furnace filled with sleepers in the hearth;

[0086] In the smelting of the open-furnace charge, the whole-furnace coke ratio of the open-furnace charge is 3.5 / t, the charging component is 60% of the maximum air volume of the blast furnace, and the binary basicity of the obtained slag is 0.83;

[0087] The molten iron charge is smelted into a first smelting stage, a second smelting stage and a third smelting stage, with a total of 16 smelting cycles;

[0088] Wherein, the first smelting stage consists of 4 smelting cycles (in the first smelting cycle, the charge to coke ratio is 3.5t / t, and the binary basicity of the slag is controlled to be 0.83); as the smelting cycle increases, the In the...

Embodiment 3

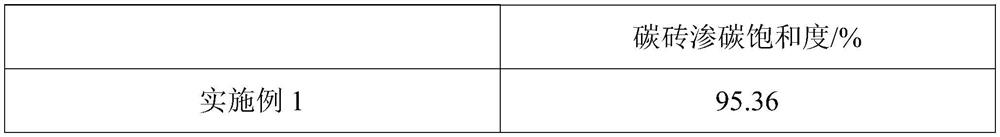

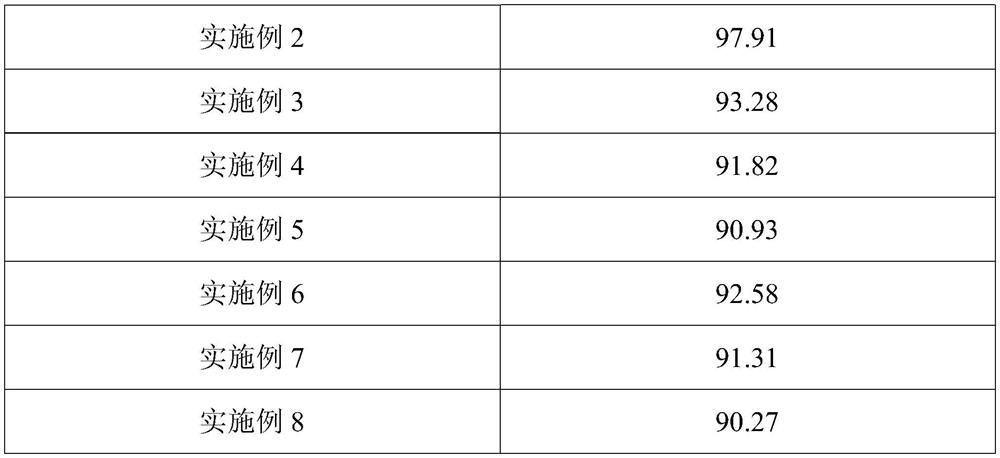

[0096] The only difference from Example 1 is that stable smelting is not performed. The carburizing saturation of carbon bricks after the furnace is completed is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com