Motor controller shell with efficient heat dissipation

A motor controller and housing technology, which is applied in the directions of chassis/cabinet/drawer parts, dispersed particle separation, dispersed particle filtration, etc. Can not achieve normal work and other problems, to achieve the effect of improving heat dissipation, saving labor, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

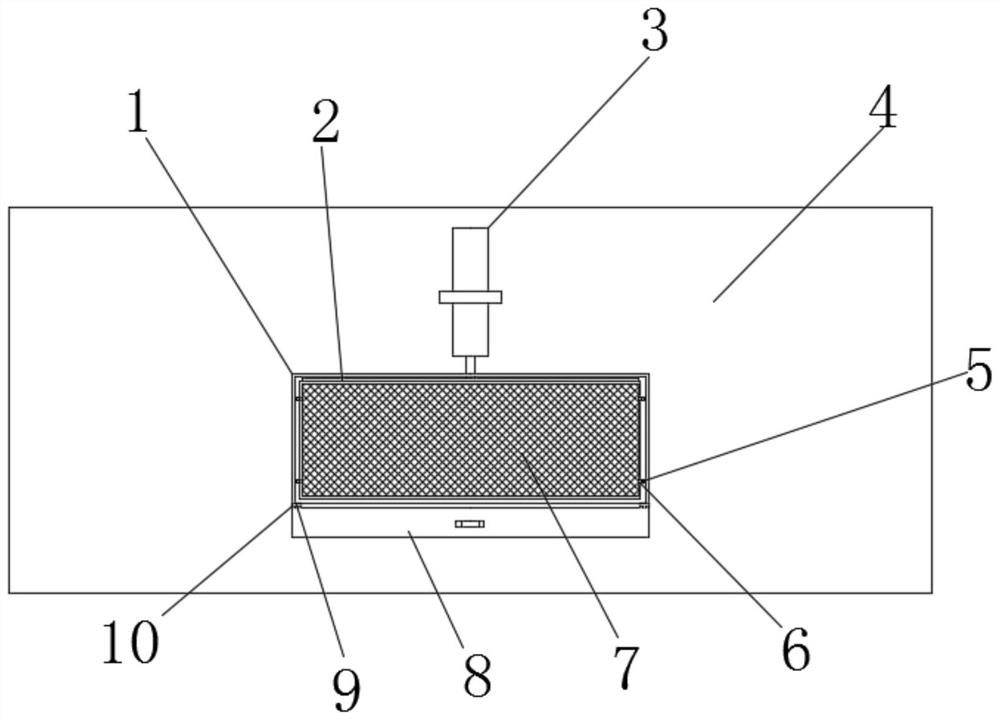

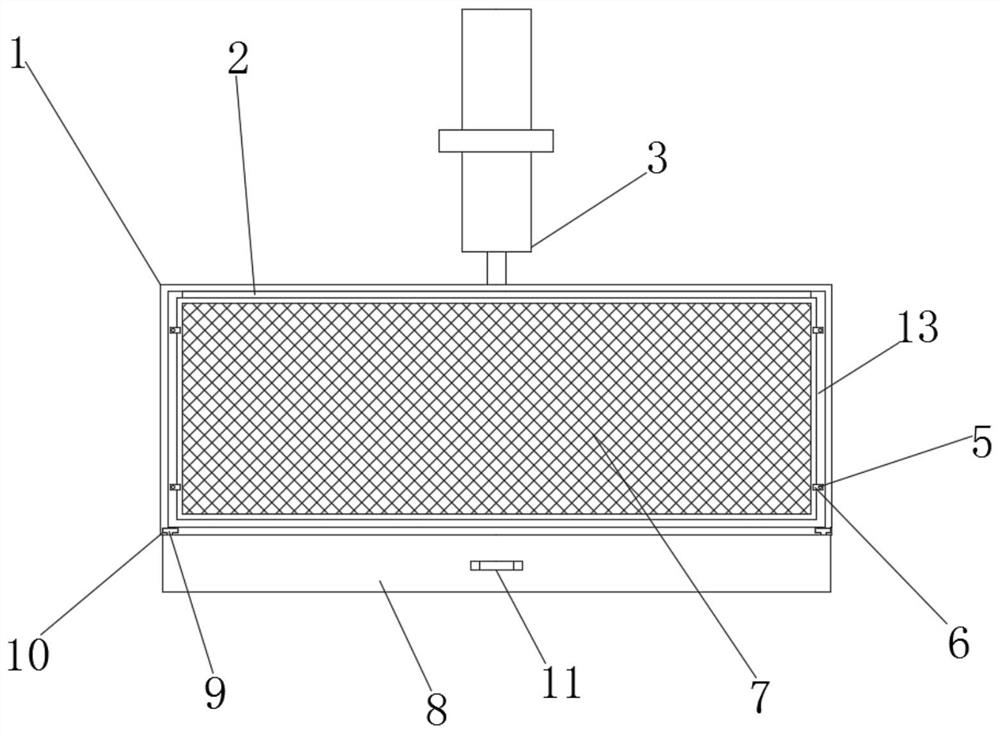

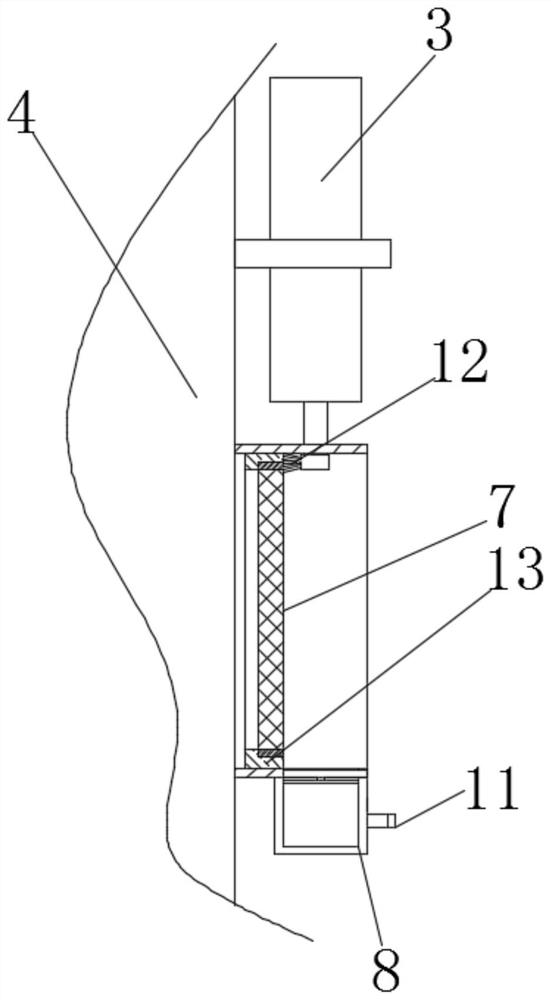

[0025] A high-efficiency heat dissipation motor controller housing, comprising a housing body 4, the front and rear side surfaces of the housing body 4 are provided with a frame plate 1 that communicates with each other, and a limit frame 13 is arranged inside the frame plate 1. A filter screen 7 is provided inside, a rotating rod 5 is provided on both sides of the surface of the limiting frame 13, and a fixing block 6 is provided at the outer end of the rotating rod 5, and the fixing block 6 is closely attached to the surface of the filter screen 7. An electric push rod 3 is provided, the electric push rod 3 is fixed on the surface of the housing body 4, and one end of the electric push rod 3 extending into the interior of the frame plate 1 is provided with a brush plate 2, and the brush plate 2 is close to the side of the filter screen 7. A brush 12 is provided; in order to collect and clean the dust on the filter screen 7, the lower end of the frame plate 1 is provided with ...

Embodiment 2

[0028] As an optional case, see Figure 4-8 , an efficient heat dissipation motor controller housing, the interior of the housing body 4 is provided with a support rod 21, the upper end of the support rod 21 is provided with a support plate 30, and the upper surface of the support plate 30 is provided with an encoder body 14, One side of the encoder body 14 is provided with a motor 15, one side of the motor 15 is provided with a controller 16, the front and rear sides of the support plate 30 are provided with an arc-shaped slide plate 24, and the upper end of the arc-shaped slide plate 24 is provided with a fan 17, and the arc-shaped slide plate 24 is provided with a fan 17. The lower end of the sliding plate 24 is provided with an arc-shaped slide rail 23, the lower end of the arc-shaped slide rail 23 is provided with a second support rod 22, the lower end of the second support rod 22 is provided with a fixed plate 18, and the lower end of the fixed plate 18 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com