Water-based graphene composite conductive paste, manufacturing method of paste and graphene heating film

A water-based graphene and composite conductive technology, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, electric heating devices, etc., can solve instability, poor thixotropy, easy clusters and Solve problems such as precipitation, achieve stable and reliable square resistance, excellent electrical conductivity, and stable and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

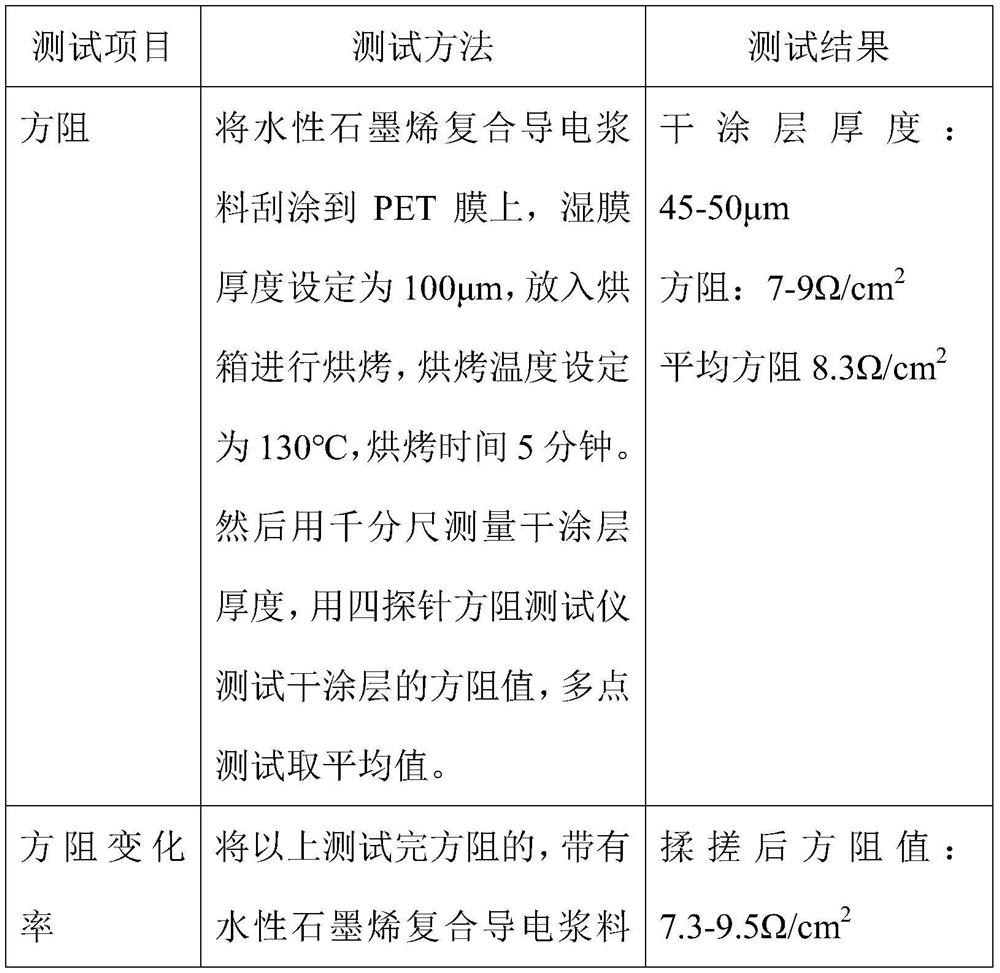

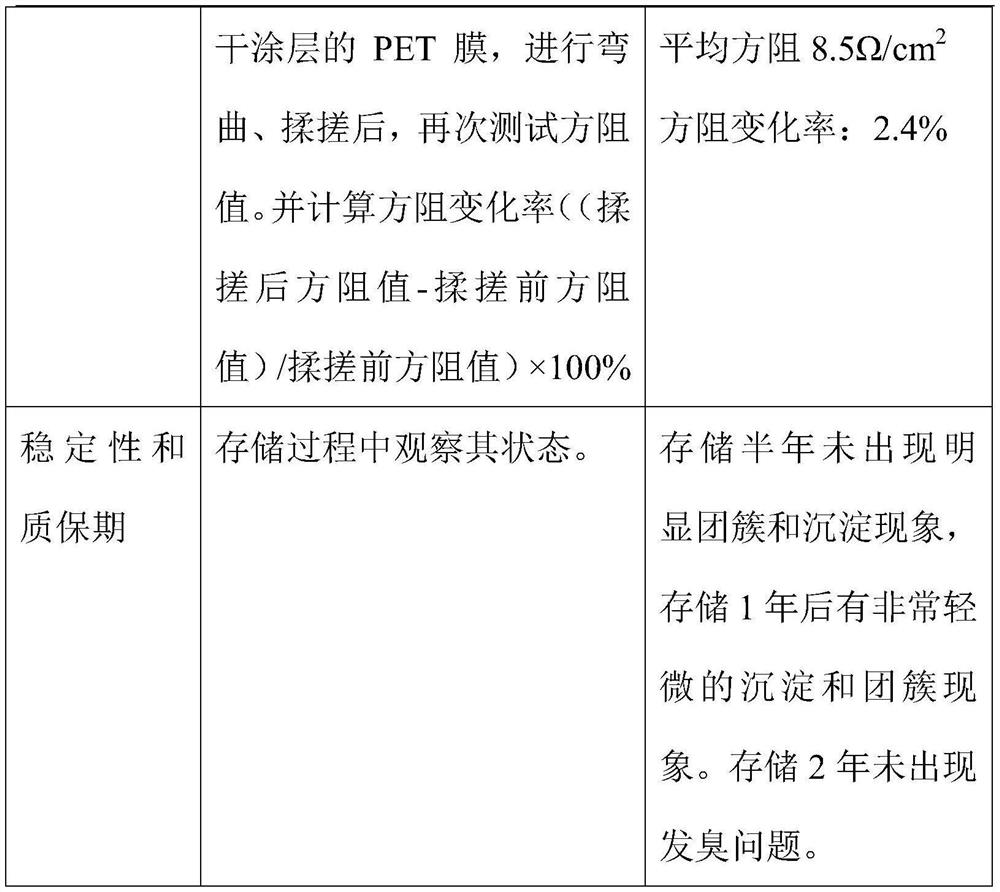

Embodiment 1

[0032] Formulation and raw materials

[0033] Deionized water (purity 99.99%), the percentage content is 47%; graphene powder (5-10 layers), the percentage content is 3%; expanded graphite powder (particle size: ≤ 10μm), the percentage content is 25%; Carbon black powder (particle size: ≤20μm), the percentage content is 10%; sulfonated castor oil, the percentage content is 1.1%; CMC carboxymethyl cellulose, the percentage content is 0.5%; technical grade urea, the percentage content is 0.3 %; caprolactam tablets, the percentage content is 0.6%; ammonia water (25%), the percentage content is 0.3%; non-ionic surfactant (908 surfactant), the percentage content is 5.1%; defoamer (BASF, Germany, Foamaster 8034A) Foaming agent), the percentage content is 1.2%; the preservative (British Thor preservative Acticide MBS), the percentage content is 0.4%; the acrylic resin, the percentage content is 5.5%.

[0034] Preparation method and steps

[0035] Step 1: Proportioning and weighing:...

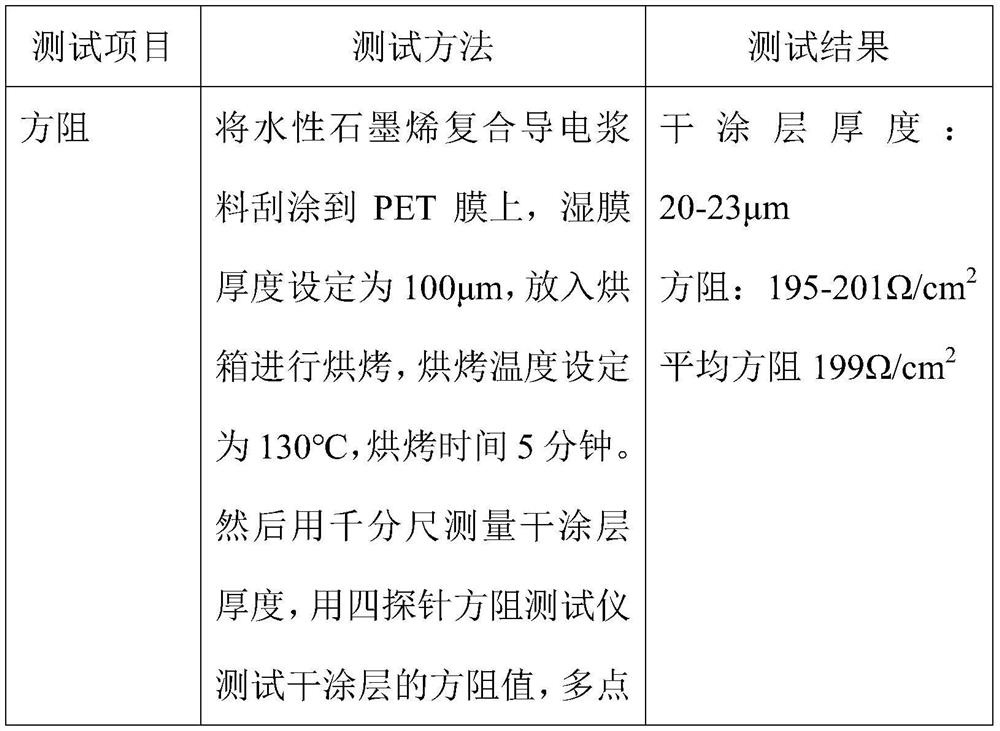

Embodiment 2

[0053] Formulation and raw materials

[0054] Deionized water (purity 99.99%), the percentage content is 65%; graphene powder (5-10 layers), the percentage content is 1%; flake graphite powder (particle size: ≤10μm), the percentage content is 11%; Carbon black powder (particle size: ≤20μm), the percentage content is 6%; talc, the percentage content is 1%; sulfonated castor oil (emulsifier), the percentage content is 1.1%; lauric acid polyoxyethylene ether (emulsified agent), the percentage content is 1.5%; CMC carboxymethyl cellulose, the percentage content is 0.5%; technical grade urea (dispersing agent), the percentage content is 0.2%; β-naphthalenesulfonate sodium formaldehyde condensate (dispersing agent), The percentage content is 0.6%; 25% ammonia water (pH regulator), the percentage content is 0.3%; 908 surfactant (non-ionic surfactant), the percentage content is 4.7%; defoaming agent (Germany BASF Foamaster8034A defoamer) , the percentage content is 1.2%; the preserva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com