Centrifugal clutch

A centrifugal clutch and ring technology, applied in the field of clutches, can solve the problems affecting the friction coefficient of the friction plate, wear of the clutch elements, inconvenient operation and use, etc., and achieve the effects of large transmission torque, improved service life and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

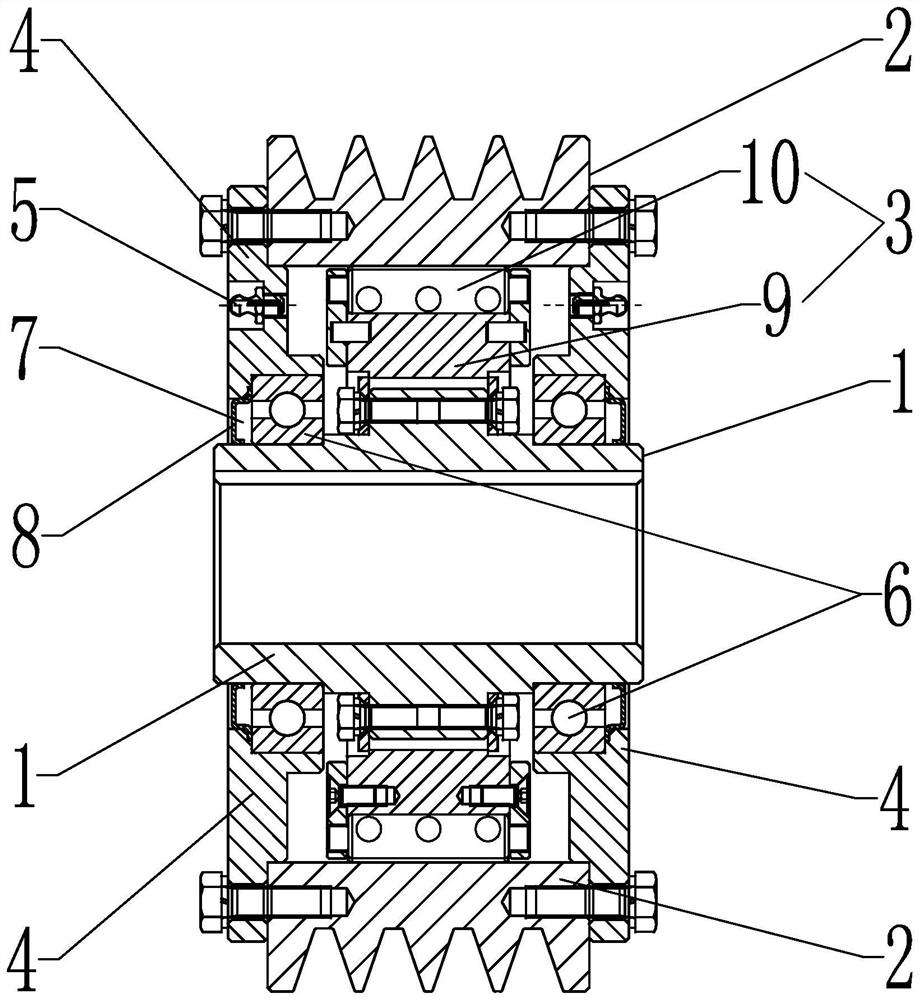

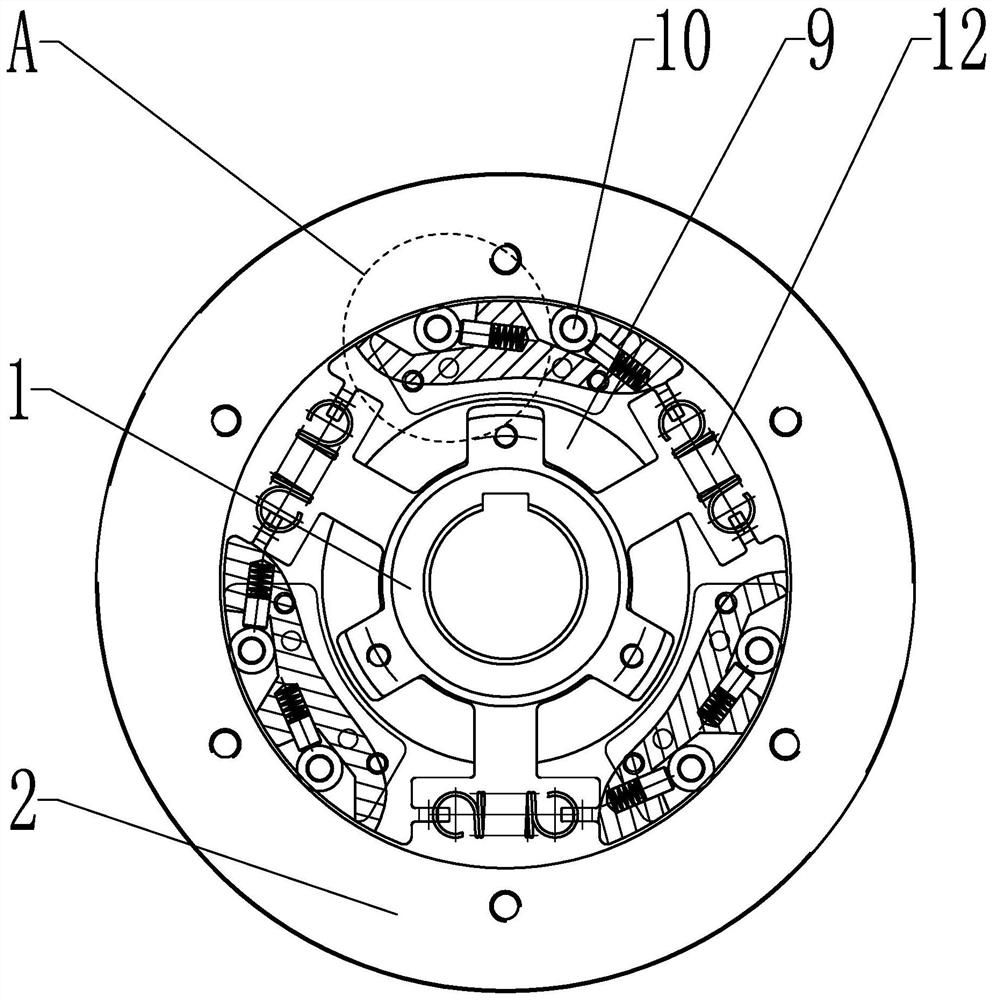

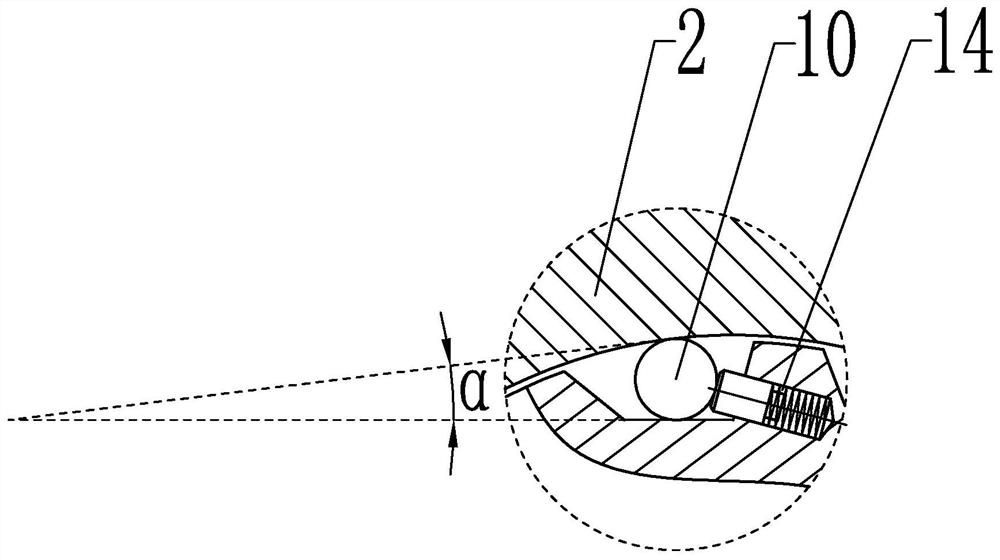

[0033] combine Figure 1 to Figure 6, this embodiment provides a centrifugal clutch, comprising: an inner ring member 1 engaged with the driving end, an outer ring member 2 engaged with the driven end, and a middle ring member 1 and the outer ring member 2 disposed between the inner ring member 1 and the outer ring member 2 between centrifuge assemblies 3. The inner ring member 1 and the outer ring member 2 are coaxially arranged, the centrifugal assembly 3 is always in driving connection with the inner ring member 1, and after the inner ring member 1 is rotated to reach the centrifugal condition, the centrifugal assembly 3 can be triggered at the same time with the outer ring member 2. Transmission connection to realize clutch operation between. A shell member 4 is arranged between the inner ring member 1 and the outer ring member 2 . The shell members 4 are respectively covered on the two outer end surfaces to form a closed inner cavity between the inner ring member 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com