Construction method of deep foundation pit earthwork ramp

A construction method and technology of deep foundation pits, applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of heterogeneous distribution of structural forms, affect the safety of foundation pits, and unfavorable project advancement, etc., to achieve convenient construction, structural safety, and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated by specific examples below.

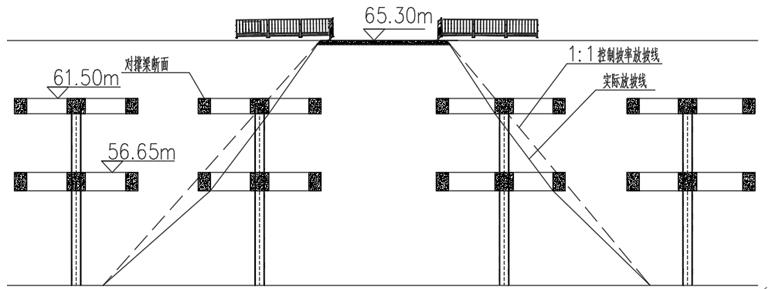

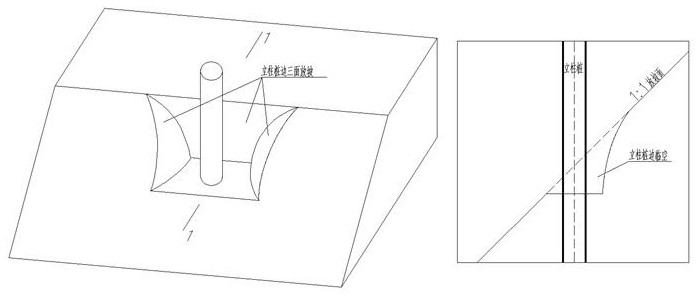

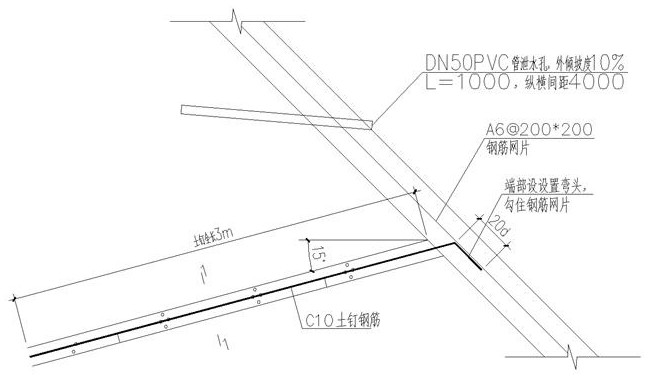

[0025] like Figure 1~Figure 3 As shown, a construction method of a deep foundation pit earthwork ramp, comprising:

[0026] Step 1. Ramp monitoring: According to the design drawings of the ramp, select the monitoring point of the foundation pit, complete the layout before the construction of the ramp, and collect the initial data; the monitoring frequency is from complex to simple, three days before the ramp is put into use, Three times a day in the morning, noon and evening; from the third to fourteenth days, once a day; after two weeks, once every three days, the monitoring time should continue until the ramp is removed;

[0027] Step 2. Ramp construction and initial grinding: Backfill the earthwork according to the designed ramp positioning and slope, starting from the bottom of the foundation pit, backfilling in layers and compacting in layers. During the backfilling process, an excavator c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com