Preparation method of low-cost high-weldability hot-rolled pickled plate for 440MPa-grade automobile structure

A hot-rolled pickling and automobile structure technology, which is applied in the field of material processing, can solve problems affecting product forming and welding performance, inclusion segregation, high alloy cost, etc., to ensure plasticity index and welding performance, refine grains, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

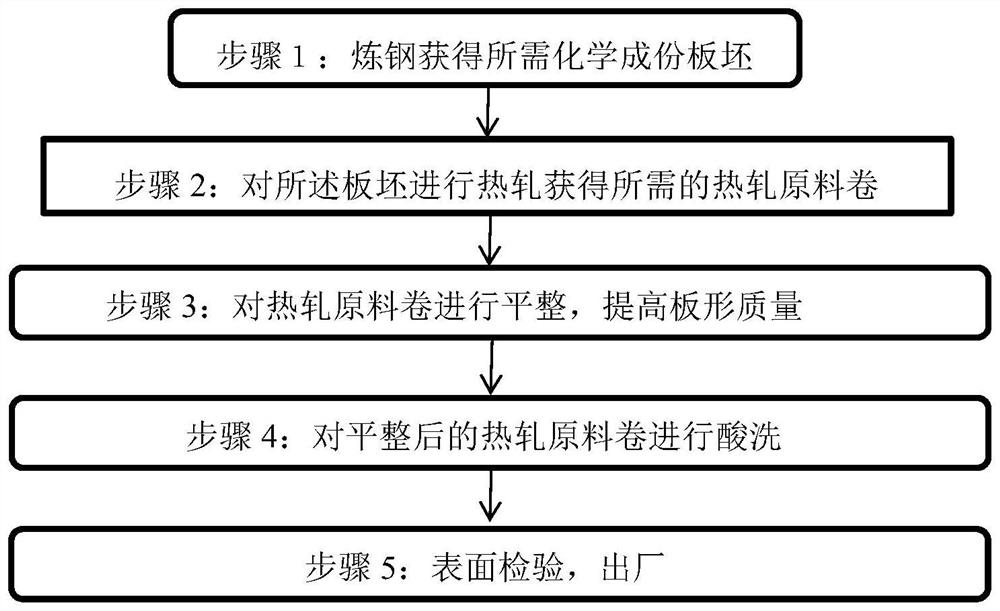

Image

Examples

Embodiment 1

[0042] Adopt the technical scheme of the patent of the present invention to manufacture the hot-rolled pickling plate for automobile structure with low cost and high weldability of 440MPa. The specific production steps are as follows:

[0043] 1. A low-cost and high-weldability 440MPa-grade hot-rolled pickling sheet for automobile structure, the chemical composition content of elements: C: 0.064%, Si: 0.17%, Mn: 1.32%, P: 0.012%, S: 0.003%, Als: 0.045%, O: 0.0025%, N: 0.003%, and the balance is Fe and inevitable inclusions.

[0044] 2. Obtain the required continuous casting slabs through steelmaking production according to the above components and weight percentages;

[0045] 3. Heating the continuous casting billet in a walking heating furnace and keeping the temperature at 1170-1250℃ for 45-90min;

[0046] 4. After the continuous casting billet is released from the furnace, it is first descaled by high-pressure water, and then rolled in the rough rolling mill. The rolling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com