Two groups of matched ink for color-overlapping gel ink pen and preparation method of two groups of matched ink for color-overlapping gel ink pen

A technology of water-based pens and inks, applied in inks, applications, household appliances, etc., can solve the problems of irregular and uncontrollable discoloration, and achieve the effects of long-term bright colors, difficult structures, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

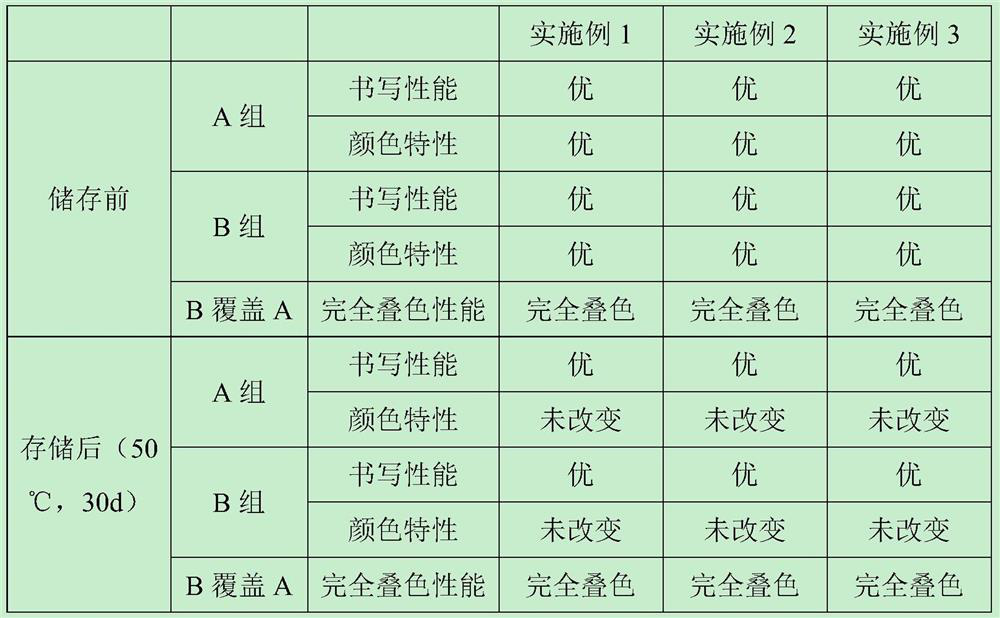

Embodiment 1

[0020] Group A ink: Add 3g anthraquinone dye to 81.9g water, stir rapidly for 20min, stir 10g glycerol, 5g propylene glycol, 0.1g ammonia water at low speed for 1h, filter to remove large particles of impurities, and the finished product is obtained;

[0021] Group B ink: 8g of PVP15, 0.5g of DISPERBYK2012 and 0.5g of polyoxyethylene fatty alcohol ether were prepared to obtain a coating material. Mix the above coating material with 35g of deionized water, add 5g of red fluorescent pigment, stir and disperse to obtain a viscous slurry, grind 0.3mm zirconium beads for 1 hour, then add 8g of propylene glycol, 10g of ten polyglycerol, 5g of acrylic resin, 2g of ethanol, 3g Potassium hydrogen sulfite, 0.2 g of ammonia water and the remaining deionized water are added, and the mixture is stirred at low speed for 1 h. Filter to remove large particles of impurities, that is, to obtain the finished product.

Embodiment 2

[0023] Group A ink: add 2g carbonium dye to 89.85g water, stir quickly for 20min, 8g decaglycerol, 0.15g ammonia water and stir at low speed for 1h, filter to remove large particles of impurities, the finished product is obtained;

[0024] Group B ink: 6g of PVP (K15:K90=1:1), 0.5g of DISPERBYK2012 and 0.6g of polyoxyethylene fatty alcohol ether were prepared to obtain a coating material. Mix the above coating material with 35g deionized water, add 3g phthalocyanine pigment, stir and disperse to obtain a viscous slurry, grind 0.3mm zirconium beads for 1 hour, then add 10g propylene glycol, 8g ten polyglycerol, 4g polyurethane resin, 3g ethanol, 4g Potassium hydrogen sulfite, 0.1 g of ammonia water and the remaining deionized water, and stir at low speed for 1 h. Filter to remove large particles of impurities, that is, to obtain the finished product.

Embodiment 3

[0026] Group A ink: Add 4g metal complex dye to 84.8g water, stir rapidly for 20min, stir 11g glycerol, 0.2g oxalic acid at low speed for 1h, filter to remove large particles of impurities, the finished product is obtained;

[0027] Group B ink: 5g of PVP (K30:K90=1:1), 0.5g of DISPERBYK2012 and 0.6g of polyoxyethylene fatty alcohol ether were prepared to obtain a coating material. Mix the above coating material with 35g of deionized water, add 3g of triarylmethane pigments, stir and disperse to obtain a viscous slurry, grind 0.3mm zirconium beads for 1 hour and then add 10g of polypropylene glycol, 8g of decaglycerol, 7g of polyurethane resin, 3g of ethanol , 3g of hydrogen peroxide, 0.4g of oxalic acid and the remaining supplementary deionized water, stirring at low speed for 1h. Filter to remove large particles of impurities, that is, to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com