Low-odor offset printing ink and preparation method thereof

An offset printing ink and low-odor technology, which can be used in inks, household utensils, applications, etc., can solve problems that affect the user's sensory experience, and achieve the effects of reducing VOC content, good environmental protection, and reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

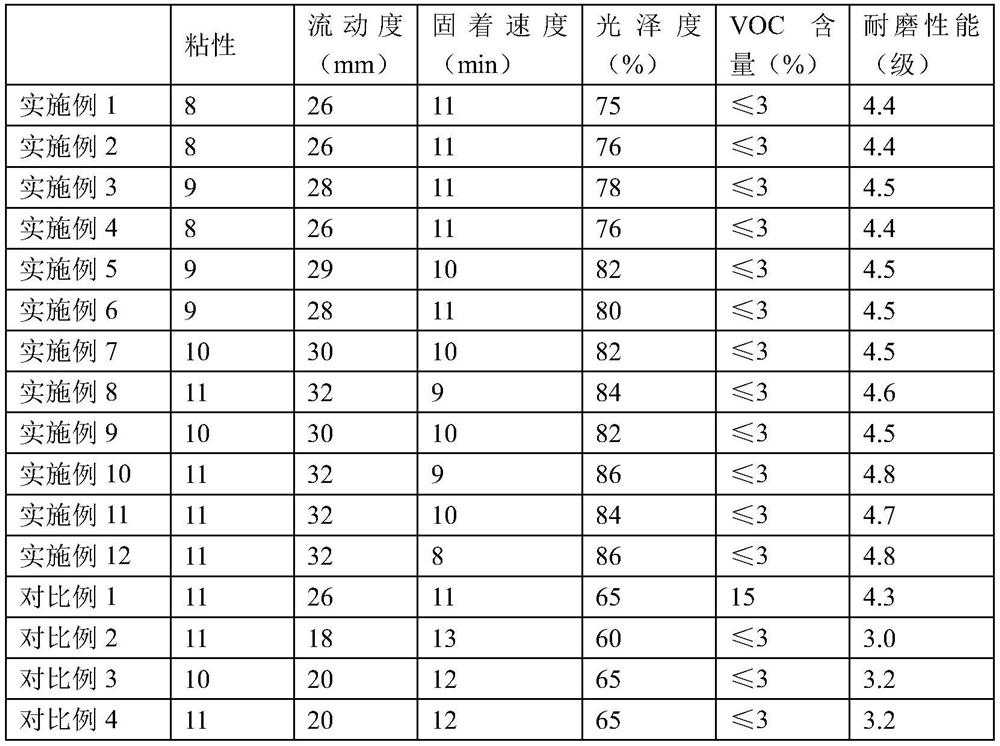

Examples

preparation example 1-3

[0038] Preparation Example 1-3 A connecting material, each raw material and the consumption of each raw material are shown in Table 1, and its preparation steps are as follows:

[0039] Each raw material was weighed according to the amount in Table 1, then the raw materials were mixed, the temperature was raised to 240° C., stirred evenly, and kept for 1.5 h to obtain a connecting material.

[0040] Among them, the soybean oil derivative is a mixture of epoxidized soybean oil pentaerythritol ester, epoxidized soybean oil propylene glycol ester, and epoxidized soybean oil ethylene glycol ester.

[0041] Each raw material of the connecting material of table 1 preparation example 1-3 and each raw material consumption (kg)

[0042] Preparation Example 1 Preparation Example 2 Preparation Example 3 Epoxidized soybean oil 30 40 50 Soybean Oil Derivatives 50 40 30 Rosin Modified Phenolic Resin 20 30 40

preparation example 4-6

[0044] A kind of anti-wear agent of preparation example 4-6, its each raw material and each raw material consumption are as shown in table 2, and its preparation step is as follows:

[0045] Each raw material is weighed according to the amount in Table 2, and then each raw material is stirred evenly to obtain the anti-wear agent.

[0046] Each raw material of the anti-wear agent of table 2 preparation example 4-6 and each raw material consumption (kg)

[0047] Preparation Example 4 Preparation Example 5 Preparation Example 6 polyethylene wax 5 8 10 Polypropylene Wax 8 6 4 polyamide wax 4 5 6

Embodiment

[0049] A kind of environmental protection offset printing ink of embodiment 1-4, its each raw material and each raw material consumption are as shown in table 3, and its preparation step is as follows:

[0050] 1) Mix epoxidized soybean oil, soybean oil derivative, and rosin-modified phenolic resin, heat up to 240° C., stir evenly, and keep the temperature for 1.5 hours to obtain a connecting material;

[0051] 2) Add pigment, filler and dispersant to the connecting material, then move the material to the three-roller for grinding 3-4 times, and measure the fineness below 10 μm, otherwise continue grinding until the fineness meets the requirements, and obtain Binder;

[0052] 3) Add vegetable oil fatty acid ester, desiccant, and anti-wear agent to the base material, mix uniformly, and stir for 40 minutes to obtain low-odor offset printing ink.

[0053] Wherein, the binder is from Preparation Example 1, the anti-wear agent is from Preparation Example 4, the desiccant is cobalt n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com