Backwash water recovery equipment

A technology for backwashing water and equipment, applied in the field of water treatment, can solve the problems of large floor space and difficult recycling of backwashing wastewater, and achieve the effects of small floor space, increased pretreatment effect, and long cleaning cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

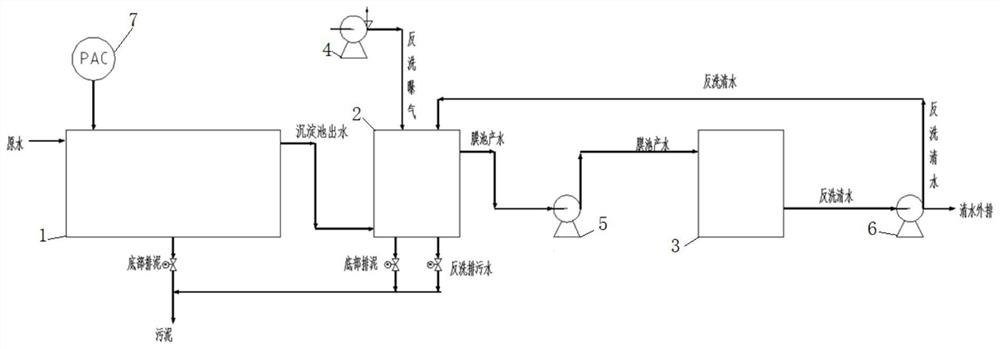

[0021] A kind of backwash water recovery equipment of the present embodiment, which includes a two-way flow inclined plate sedimentation tank 1, a membrane tank 2, a clean water tank 3, a blower 4, a production water pump 5 and a backwash pump 6;

[0022] The two-way flow inclined plate sedimentation tank 1 is provided with a liquid inlet, the water outlet of the two-way flow inclined plate sedimentation tank 1 is connected with the water inlet of the membrane tank 2 through a pipeline, and the bottom of the two-way flow inclined plate sedimentation tank 1 is provided with a liquid inlet. Mud discharge port; the gas inlet of described membrane pool 2 is communicated with the air outlet of blower 4 through pipelines; the bottom of membrane pool 2 is provided with a mud discharge port and a sewage outlet; the water produced after the filtration of membrane pool 2 passes through the production water pump 5 is pumped into the clean water tank 3; the water outlet of the clean water ...

Embodiment 2

[0026] A kind of backwash water recovery equipment of the present embodiment, which includes a two-way flow inclined plate sedimentation tank 1, a membrane tank 2, a clean water tank 3, a blower 4, a production water pump 5 and a backwash pump 6;

[0027] The two-way flow inclined plate sedimentation tank 1 is provided with a liquid inlet, the water outlet of the two-way flow inclined plate sedimentation tank 1 is connected with the water inlet of the membrane tank 2 through a pipeline, and the bottom of the two-way flow inclined plate sedimentation tank 1 is provided with a liquid inlet. Mud discharge port; the gas inlet of described membrane pool 2 is communicated with the air outlet of blower 4 through pipelines; the bottom of membrane pool 2 is provided with a mud discharge port and a sewage outlet; the water produced after the filtration of membrane pool 2 passes through the production water pump 5 is pumped into the clean water tank 3; the water outlet of the clean water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com