Tray palletizing robot with adjustable applicable width

A technology of palletizing robots and pallets, which is applied in the direction of object depalletizing, object stacking, transportation and packaging, etc. It can solve the problems of difficulty in adapting to the width of pallets of different specifications and difficulty in adjustment, so as to achieve quick adjustment, improved stability, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

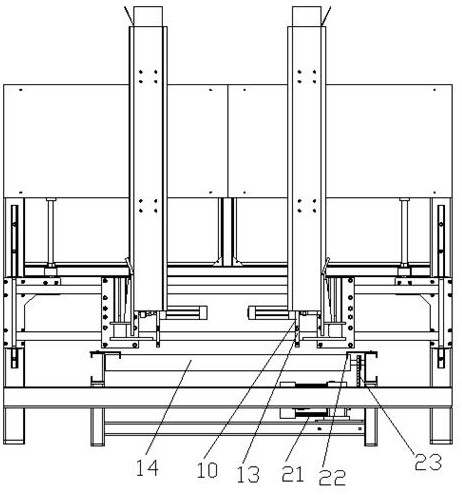

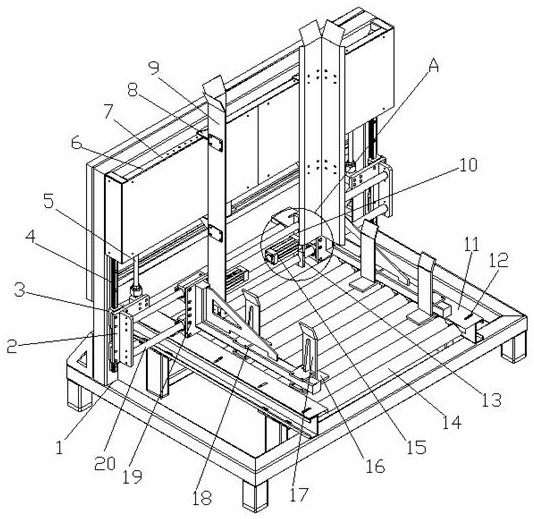

[0021] see Figure 1~Figure 3 , the embodiments of the present invention include:

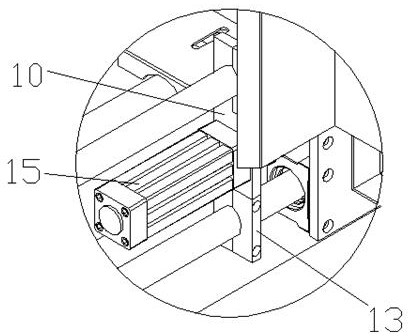

[0022] like figure 1 and figure 2 The shown palletizing robot with adjustable width includes: frame 1, roller 14, clamping arm 18, sliding bar 20, first sliding seat 2, second sliding seat 19, first sliding seat driving device 5 and The second carriage drive 15 . The drum 14 is arranged in the frame 1 at intervals in the front and rear. In this embodiment, a passive sprocket is arranged at one end of the drum 14 , a chain 23 for l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com