Master-slave bidirectional control method and system for redundant degree-of-freedom teleoperation robot

A robot main and two-way control technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of reducing the sense of presence and operation accuracy, not feeling the feedback force, and laborious operation of the main hand, so as to enhance the sense of presence, The effect of reducing shock and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

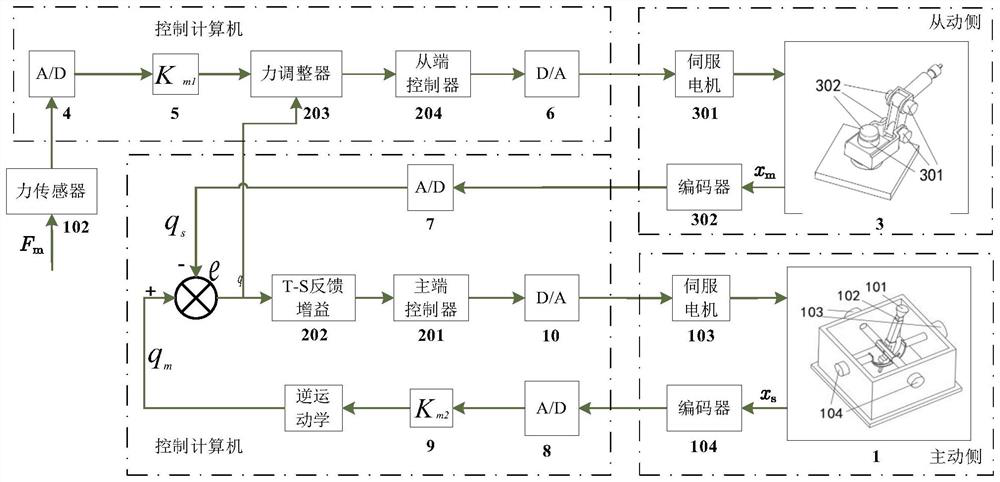

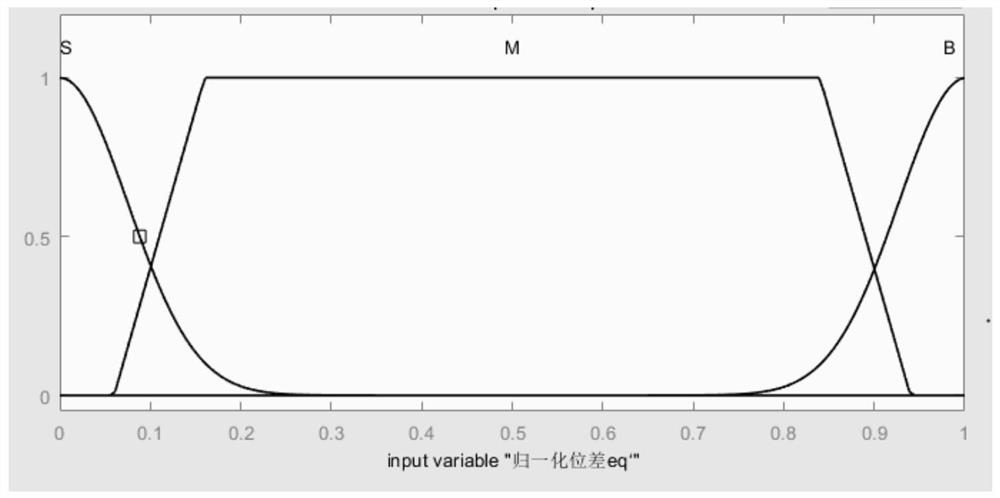

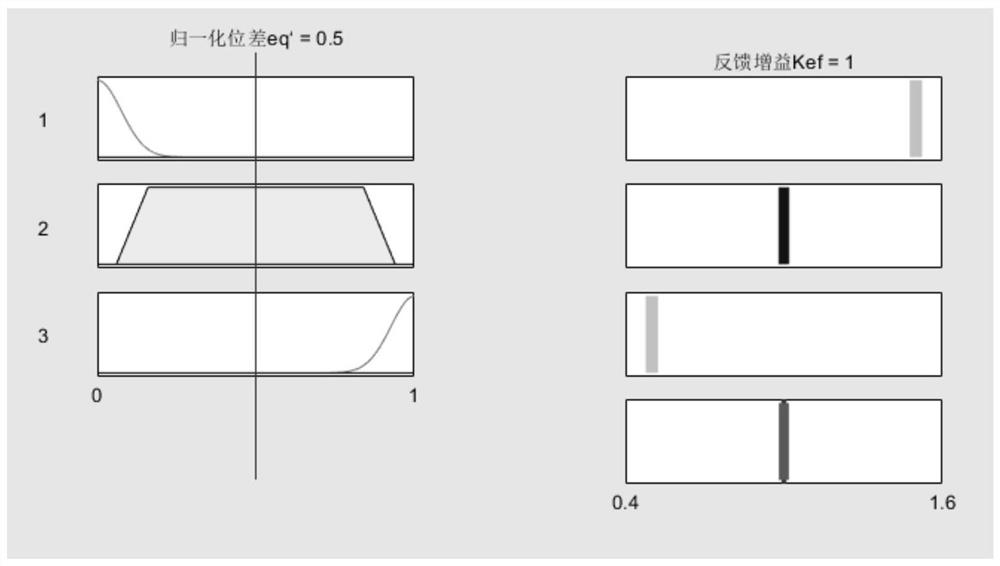

[0039] like Figure 1-4 As shown, on the one hand, the present invention provides a master-slave bidirectional control system for a redundant degree-of-freedom teleoperated robot, which includes a master manipulator 1, a computer control unit 2 and a slave manipulator 3, and the master manipulator 1 has two mutual The rotational degrees of freedom in the vertical direction, including the joystick 101, the three-dimensional force sensor 102, the servo motor 103 and the absolute value encoder 104, the slave manipulator 3 has four rotational degrees of freedom and the rotary joint is fixedly installed with a servo motor 301 and an absolute value The encoder 302, the computer control unit 2 includes a master-side controller 201, a T-S feedback gain 202, a force regulator 203, a slave-side controller 204 and a calculation module (not shown in the figure, which is used to cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com