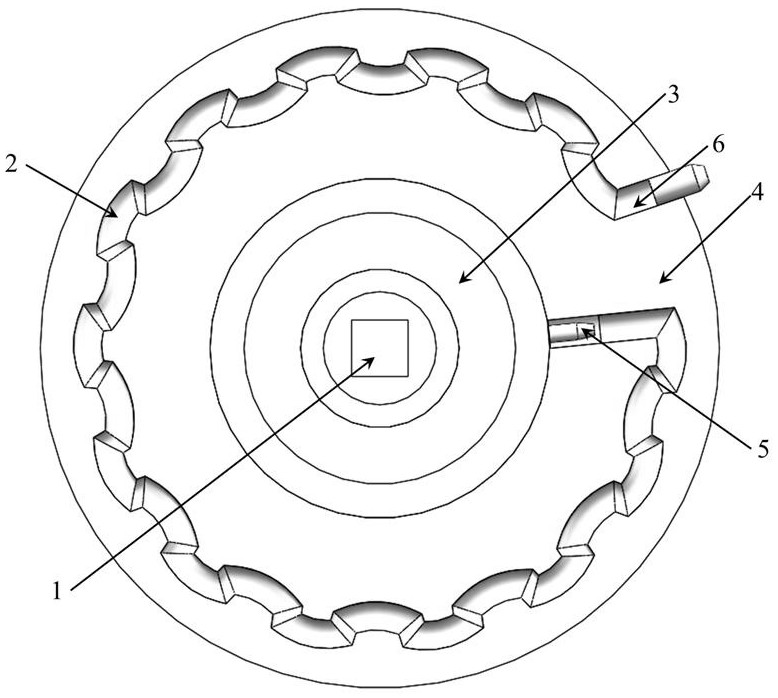

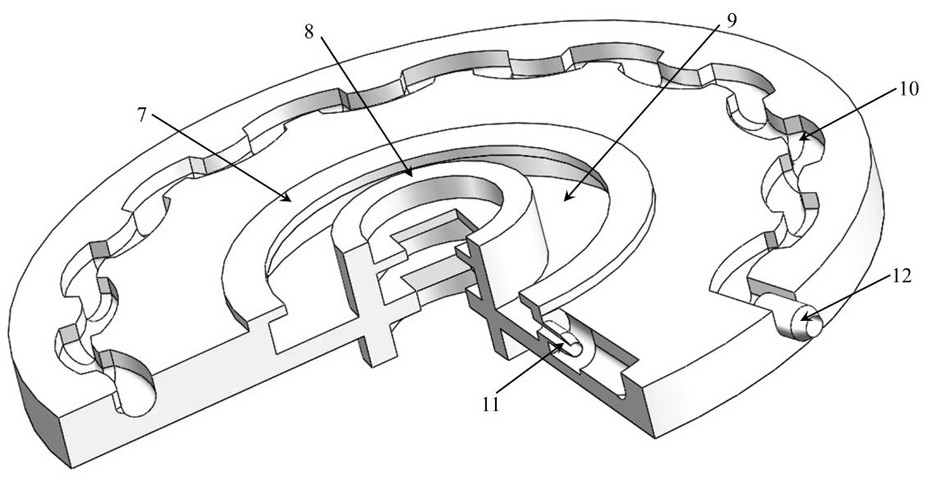

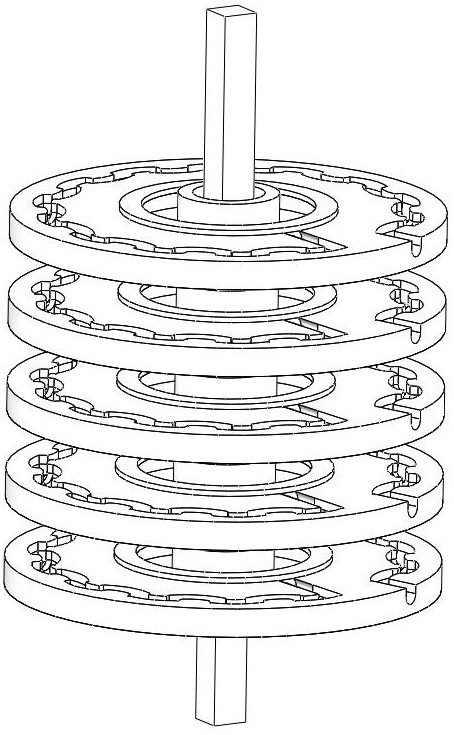

Continuous flow reactor with controllable residence time and design and use method thereof

A residence time and reactor technology, applied in chemical instruments and methods, fluid mixers, mixers, etc., can solve the problems of short residence time of reactants, high microchannel pressure, and low reaction efficiency, and it is not easy to achieve residence time. Control, the effect of easy control of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0063] Sodium alginate with a viscosity of 2.52Pa·s was added to the ink as the test medium. The test medium is pumped into the liquid storage chamber 3 as a buffer through the peristaltic pump, and the test medium enters the reaction channel through the channel inlet under the action of centrifugal force. Change the motor speed to get as Figure 4 results shown. In the figure, (a), (b), (c) are the conditions of small rotation speed, and (d), (e), and (f) are conditions of large rotation speed. Depend on Figure 4 It can be known that the residence distribution of the two situations in the channel can be achieved by changing the motor speed, and the material residence time can be controlled by controlling the inlet speed of the material.

example 2

[0065] Nano-silver was prepared by using 15Pa·s sodium alginate and silver nitrate as reactants, and the reaction was carried out at 80℃ in a continuous flow reactor with controllable residence time. The sodium alginate and silver nitrate are mixed uniformly at room temperature, and the sodium alginate and silver nitrate basically do not react at this temperature. The mixture is pumped into the buffer by the peristaltic pump, and the test medium enters the reaction channel through the channel inlet under the action of centrifugal force. The motor speed was kept at 1000rpm for 30min.

[0066] Figure 5 It is the XRD pattern of nano-silver, which shows the X-ray diffraction pattern of the reaction of 0.05mol / L silver nitrate and sodium alginate to produce nano-silver. The crystal planes (111), (200), (220) and (311) in the figure are consistent with the 04-0783 silver in the standard card JCPDS, indicating that the nano-silver generated by the reaction has a face-centered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com