Defoaming filter

A filter and defoaming technology, which is applied in the direction of filtration separation, filtration circuit, chemical instruments and methods, etc., can solve the problems of easy generation of air bubbles in oil, reduce the service life of equipment, and cavitation, so as to improve the defoaming effect and increase the Effect of large contact area and expanded defoaming range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

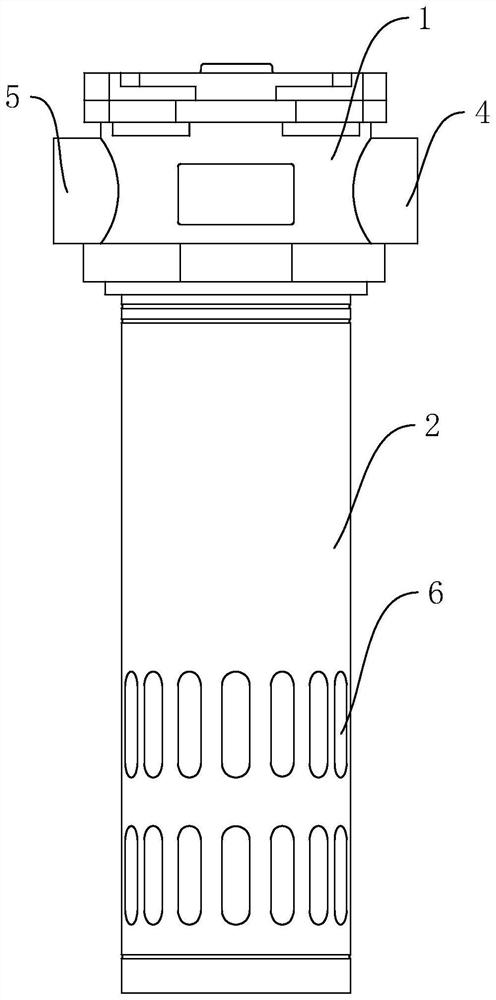

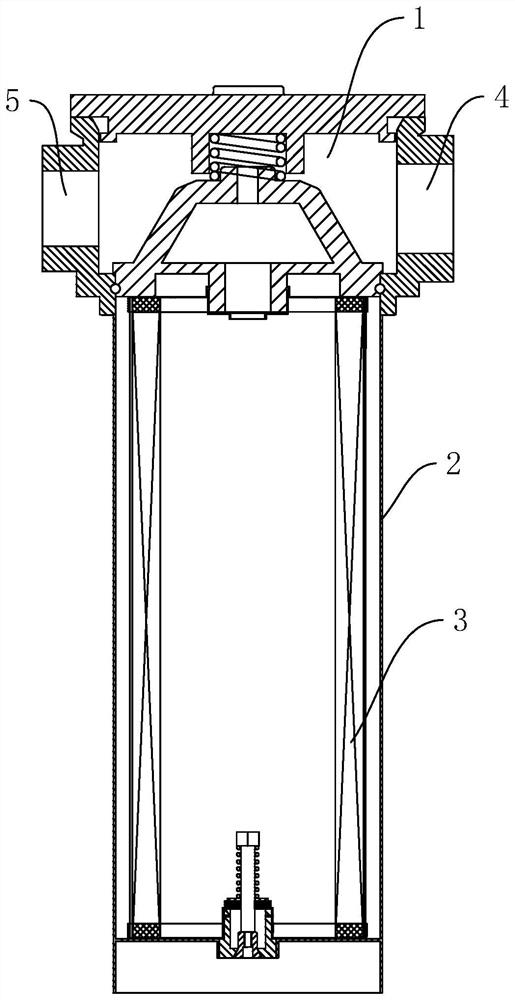

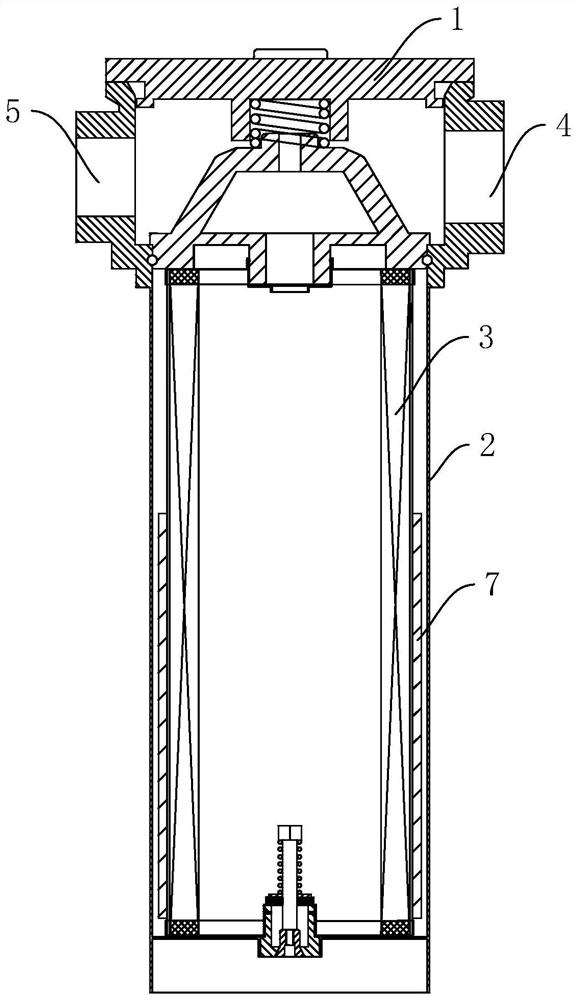

[0033] refer to Figure 3-4 , which is a defoaming filter disclosed in the present invention, comprising a filter head 1 , a filter cartridge 2 and a filter element 3 . The filter head 1 is provided with an oil inlet 4 and a sensor connection port 5, the oil inlet 4 is the inlet for the oil to enter the filter, and the sensor connection port 5 is used to connect the sensor used with the filter. The filter cartridge 2 and the filter element 3 are both cylindrical, the filter cartridge 2 and the filter element 3 are connected with the filter head 1, the filter element 3 is located inside the filter cartridge 2, the filter element 3 is communicated with the filter head 1, and the bottom of the side wall of the filter cartridge 2 Several oil outlet holes 6 are provided.

[0034] The bottom of the filter element 3 is sleeved with a defoaming filter screen cartridge 7, which is located between the filter element 3 and the filter cartridge 2, and the position of the defoaming filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com