Ball bead supporting bridging sample anti-blocking drainage device for vacuum sealing drainage

A technology of supporting bridges and balls, applied in the direction of suction devices, dressings, viscous dressings, etc., can solve the problems of weakening the effect and efficiency of VSD devices, poor negative pressure conduction, difficulty in suction, etc., and achieve the possibility of compressive necrosis of tissue cells Sexual weakening, continuous effective continuous rebound, continuous effective drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

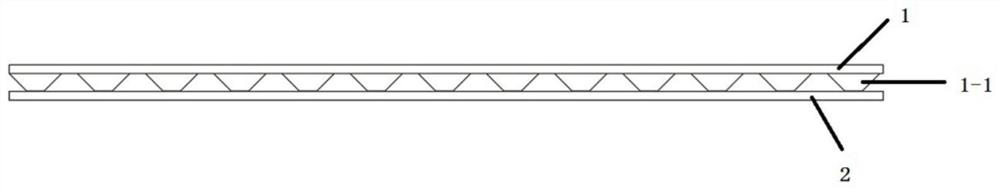

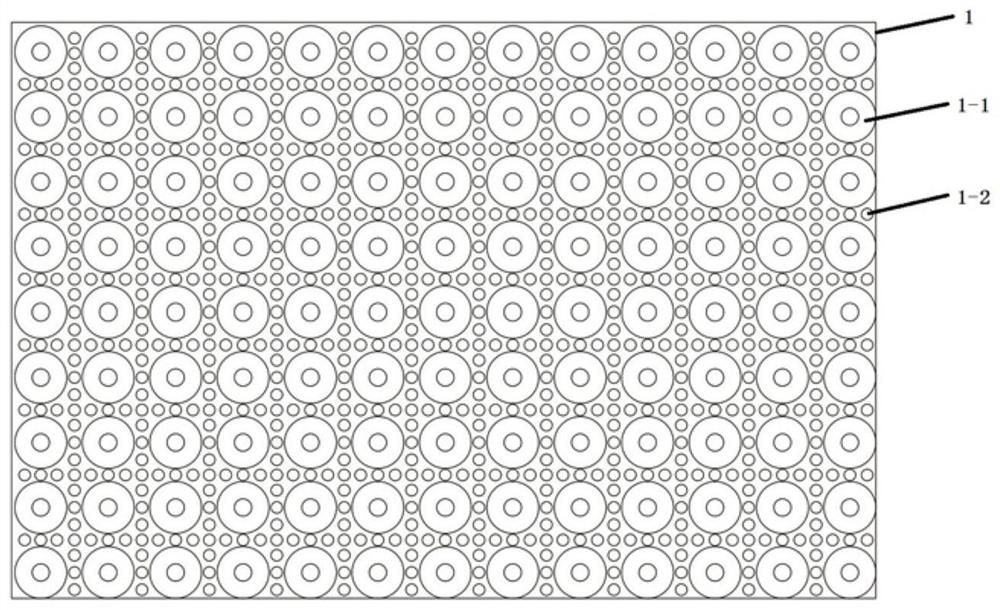

[0055] like Figures 1 to 3 As shown, this embodiment is a preferred structure, specifically a ball-supported bridge-like anti-blocking and drainage device for negative pressure closed drainage, including an upper support layer 1 and a lower drainage layer 2; the upper support layer 1 is evenly distributed There are a plurality of drainage holes 1-2, the upper surface of which is a smooth plane, which is easy to be sealed with a medical sealing film, and a plurality of ball supports 1-1 are evenly distributed on the lower surface, the ball supports 1-1 and the lower drainage layer 2 The radius of the circular bottom surface of the opposite lower surface is smaller than the radius of the circular bottom surface of the upper surface, thereby forming a downwardly convex truncated cone, and the drainage holes 1-2 are evenly distributed around the ball support 1-1.

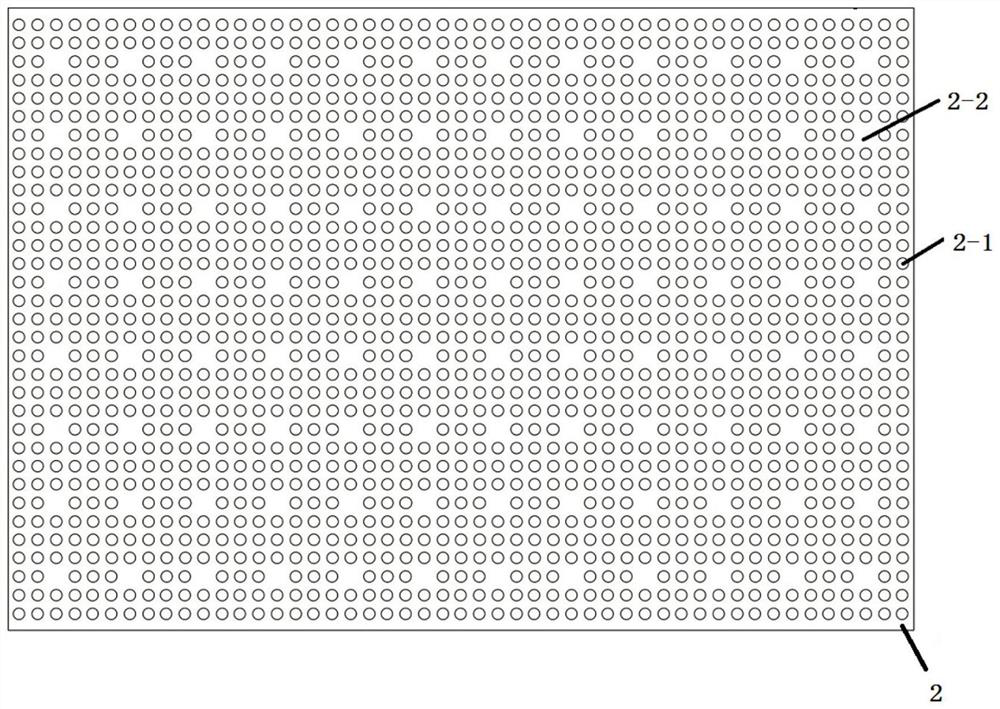

[0056] The lower drainage layer 2 is evenly distributed with a plurality of supporting surfaces 2-2, the supporting ...

Embodiment 2

[0068] like Figures 6 to 7 As shown in the figure, another preferred structure is proposed in this embodiment. The difference from Embodiment 1 lies in that the supporting surface 2-2 of the lower drainage layer 2 is provided with connecting holes 2-3, and the balls of the upper supporting layer 1 support the 1- The lower surface of 1 is embedded in the connection holes 2-3, and is fixed with the lower drainage layer 2, which can not only play a supporting role, but also ensure smoothness and no blockage.

[0069] Since the supporting surface 2-2 of the lower drainage layer 2 of this structure is provided with a connecting hole 2-3, and the lower surface of the ball support 1-1 of the upper supporting layer 1 is embedded in the connecting hole 2-3, the upper and lower parts of the structure are When the layers are combined, the overall thickness is 1 mm less than the structure of Example 1, which is 4 mm thick. This design has the following three beneficial effects: 1. The l...

Embodiment 3

[0071] like Figures 8 to 9 As shown in the figure, another preferred structure is proposed in this embodiment. The difference from Embodiment 1 is that the middle part of the ball support 1-1 of the upper support layer 1 is provided with a connecting groove 1-3, and the support surface 2 of the lower drainage layer 2 is provided with a connecting groove 1-3. -2 is provided with a connecting body 2-4, the connecting body 2-4 is embedded in the connecting groove 1-3 to limit and fix, which plays a supporting role and ensures smoothness and no blockage.

[0072] Since the middle part of the ball support 1-1 of the upper support layer 1 is provided with a connecting groove 1-3, the supporting surface 2-2 of the lower drainage layer 2 is provided with a connecting body 2-4, and the connecting body 2-4 is embedded in the connecting groove 1 -3 The inner limit is fixed, so the structure has the following two beneficial effects: 1. The limit effect is stronger than that of Embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com