Preparation method and application of collagen peptide magnesium chelate

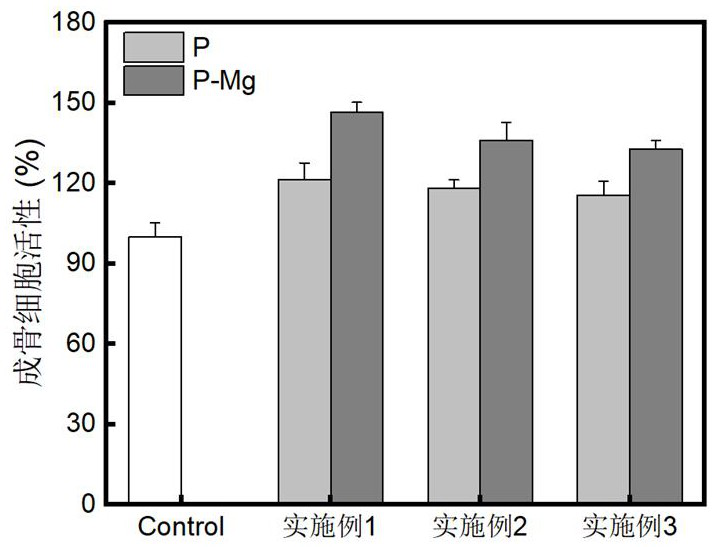

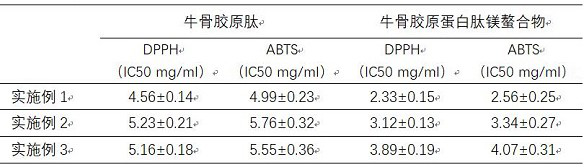

A collagen peptide and magnesium chelate technology, applied in the biological field, can solve the problems of osteoporosis, bone formation and bone resorption imbalance, and achieve the effect of improving antioxidant activity, avoiding side effects, and low operating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Preparation of bovine collagen peptides

[0031] Take a certain amount of defatted and decalcified beef bones, add deionized water at a ratio of 1:4, adjust the pH of the solution to 8.0, add alkaline protease and papain at 1.0% and 0.75% of the mass of the beef bones, respectively, at 60 ℃ Enzymatic hydrolysis was carried out for 2 h, and then the enzyme was inactivated by boiling water bath for 15 min. Filtration dialysis was filtered through filter cotton, and then the ions introduced by adjusting the pH during the reaction were removed through a 200 Da dialysis bag, concentrated by a rotary evaporator, and rotary evaporated. The temperature is 60°C; then freeze-drying is performed, and the conditions for freeze-drying are cold hydrazine-60°C, and the drying chamber is 10°C, and then bovine collagen peptide P is prepared.

[0032] Step 2: Preparation of bovine collagen peptide magnesium chelate

[0033] The prepared bovine collagen peptide is dissolved at a ...

Embodiment 2

[0035] Step 1: Preparation of bovine collagen peptides

[0036] Take a certain amount of defatted and decalcified beef bones, add deionized water at a ratio of 1:4 to the liquid, adjust the pH of the solution to 8.0, add alkaline protease and papain at 0.75% and 0.75% of the mass of the beef bones, respectively, at 60 ℃ Enzymatic hydrolysis was carried out for 2 h, and then the enzyme was inactivated by boiling water bath for 15 min. Filtration dialysis was filtered through filter cotton, and then the ions introduced by adjusting the pH during the reaction were removed through a 200 Da dialysis bag, concentrated by a rotary evaporator, and rotary evaporated. The temperature is 60°C; then freeze-drying is performed, and the conditions for freeze-drying are cold hydrazine-60°C, and the drying chamber is 10°C, and then bovine collagen peptide P is prepared.

[0037] Step 2: Preparation of bovine collagen peptide magnesium chelate

[0038] The prepared bovine collagen peptide was...

Embodiment 3

[0040] Step 1: Preparation of bovine collagen peptides

[0041] Take a certain amount of defatted and decalcified beef bones, add deionized water at a ratio of 1:4 to the liquid, adjust the pH of the solution to 8.0, add alkaline protease and papain at 1.0% and 0.5% of the mass of the beef bones, respectively, at 60° C. Enzymatic hydrolysis was carried out for 2 h, and then the enzyme was inactivated by boiling water bath for 15 min. Filtration dialysis was filtered through filter cotton, and then the ions introduced by adjusting the pH during the reaction were removed through a 200 Da dialysis bag, concentrated by a rotary evaporator, and rotary evaporated. The temperature is 60°C; then freeze-drying is performed, and the conditions for freeze-drying are cold hydrazine-60°C, and the drying chamber is 10°C, and then bovine collagen peptide P is prepared.

[0042] Step 2: Preparation of bovine collagen peptide magnesium chelate

[0043]The prepared bovine collagen peptide was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com